Jun . 30, 2025 10:21 Sanawa dolan

Eco-Friendly Granite Measuring Tools

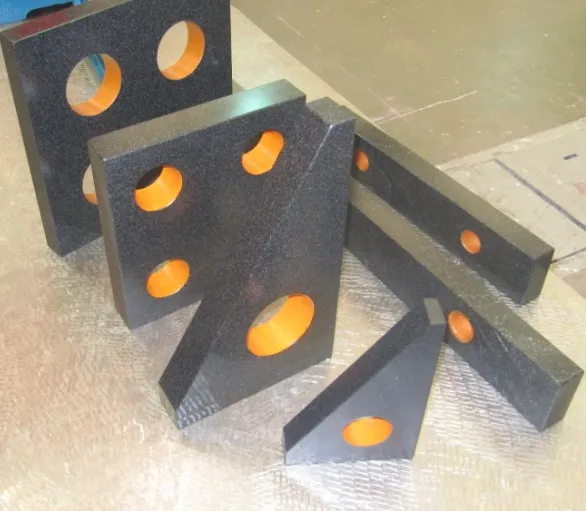

In an era where sustainability and precision are paramount, industries are increasingly turning to materials and tools that align with eco-friendly practices without compromising performance. Granite, a natural stone renowned for its durability and stability, has emerged as a cornerstone in manufacturing high-precision measuring and industrial tools. This article explores how granite small tools, granite measuring tool, and granite industrial tools are revolutionizing industries by combining environmental responsibility with unmatched accuracy.

The Role of Granite Small Tools in Sustainable Manufacturing

Granite small tools are indispensable in applications requiring meticulous precision, such as laboratory equipment, calibration devices, and specialized machining components. Unlike synthetic materials, granite is quarried directly from the earth, minimizing the carbon footprint associated with manufacturing. Its natural composition eliminates the need for energy-intensive processes like smelting or chemical treatments, making it inherently eco-friendly.

The longevity of granite small tools further enhances their sustainability. Granite’s resistance to wear, corrosion, and temperature fluctuations ensures these tools have a lifespan decades longer than alternatives like steel or aluminum. This reduces the frequency of replacements, curbing waste and resource consumption. Additionally, granite is 100% recyclable. At the end of its lifecycle, it can be repurposed into construction materials or crushed for industrial applications, ensuring zero landfill contribution.

Industries such as aerospace, automotive, and electronics rely on granite small tools for tasks demanding sub-micron accuracy. For example, granite surface plates are used to calibrate precision instruments, ensuring machinery operates within strict tolerances. By choosing granite, manufacturers not only achieve operational excellence but also align with global sustainability goals.

Precision and Durability: The Advantages of Granite Measuring Tool

A granite measuring tool is the gold standard in metrology, the science of measurement. Granite’s low thermal expansion coefficient ensures dimensional stability even in fluctuating temperatures, a critical feature for maintaining accuracy in environments like quality control labs or production floors.

The eco-friendly credentials of granite measuring tool stem from its minimal maintenance requirements. Unlike metal tools, granite does not require lubricants or coatings that could leach harmful chemicals. Routine cleaning with water and mild detergent suffices, reducing the use of toxic cleaning agents. Furthermore, granite’s non-porous surface prevents bacterial growth, making it ideal for industries like pharmaceuticals or food processing where hygiene is paramount.

In practice, granite measuring tool such as straightedges, squares, and coordinate measuring machine (CMM) bases provide unparalleled flatness. For instance, a granite straightedge can maintain a flatness tolerance of ±0.001 mm over several meters, ensuring product consistency. This precision reduces material waste during manufacturing, as components are produced correctly the first time.

Enhancing Efficiency with Granite Industrial Tools

Granite industrial tools are the backbone of heavy-duty applications, including machine bases, optical assemblies, and vibration-damping platforms. Granite’s inherent dampening properties absorb vibrations, a feature critical in high-speed machining or semiconductor manufacturing. This reduces energy waste caused by machine recalibrations and downtime.

The sustainability of granite industrial tools is amplified by their energy-efficient production. Quarrying and shaping granite consume less energy compared to processing metals or polymers. Moreover, granite’s weight and stability eliminate the need for additional reinforcement structures, simplifying installation and reducing material use.

In sectors like renewable energy, granite industrial tools play a pivotal role. Wind turbine manufacturers use granite-based fixtures to assemble rotor blades with micron-level precision, ensuring optimal aerodynamic performance. Similarly, solar panel producers rely on granite alignment tools to position photovoltaic cells accurately, maximizing energy capture.

FAQs About Eco-Friendly Granite Measuring Tools

How does a granite measuring tool maintain accuracy over time?

Granite’s minimal thermal expansion and resistance to wear ensure that a granite measuring tool retains its dimensional stability for decades. Regular calibration checks are rarely needed, reducing maintenance interruptions.

Are granite small tools suitable for high-temperature environments?

Yes. Granite small tools can withstand temperatures up to 120°C without warping, making them ideal for industries like metalworking or glass manufacturing.

What makes granite industrial tools more sustainable than steel alternatives?

Granite industrial tools require no coatings or lubricants, last longer, and are fully recyclable. Their production also generates fewer greenhouse gases compared to steel fabrication.

Can granite measuring tool be customized for specific applications?

Absolutely. Manufacturers can tailor the size, shape, and surface finish of a granite measuring tool to meet unique industrial requirements, ensuring versatility without compromising sustainability.

How do granite industrial tools contribute to energy efficiency?

By dampening vibrations and reducing machine downtime, granite industrial tools lower energy consumption. Their stability also minimizes the need for recalibrations, further conserving power.

The shift toward eco-friendly granite measuring tools reflects a broader industrial commitment to sustainability and precision. Granite small tools, granite measuring tool, and granite industrial tools exemplify how natural materials can drive innovation while reducing environmental impact. By integrating these tools into their processes, manufacturers achieve not only operational excellence but also a greener future. As industries continue to prioritize eco-conscious practices, granite’s role as a sustainable, high-performance material will only expand.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlHabarlarAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseHabarlarAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsHabarlarAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesHabarlarAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingHabarlarAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlHabarlarAug.05,2025

Baglanyşykly önümler