ก.ย. . 25, 2024 09:50 กลับไปที่รายการ

Why Granite Surface Plates Outperform Other Materials

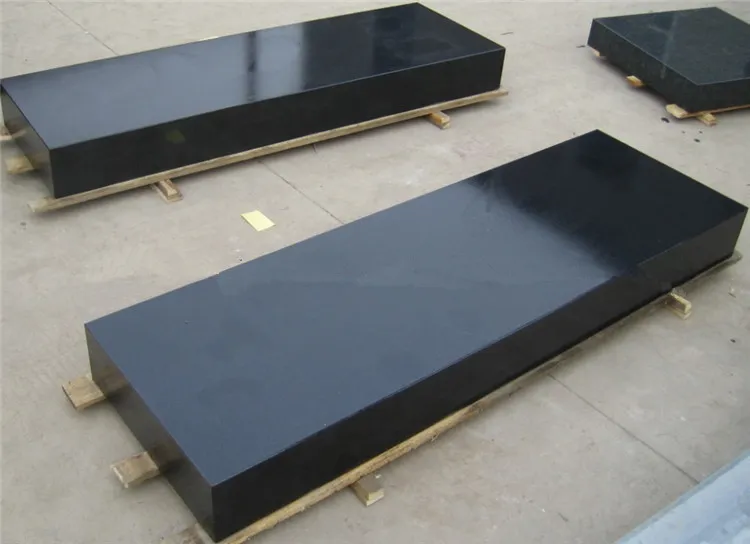

Precision is the foundation of any successful industrial or fabrication process. Whether it's for measuring, marking, or inspecting, the tool you use must be of the highest quality to ensure accuracy. Enter the granite surface plate, an essential tool for industries that demand perfection. The granite surface plate is known for its superior accuracy, and it has become the gold standard in many sectors, including manufacturing, engineering, and quality control. In this article, we’ll dive into why granite surface plates for sale stand out compared to cast iron, the importance of granite surface plate with stand, and how they compare to other options such as fabrication tables. Read on to understand why investing in a granite surface plate is essential for your enterprise’s precision needs.

Why Choose a Granite Surface Plate for Sale Over Cast Iron?

The accuracy of granite surface plates is much higher than that of cast iron platforms. This is due to several reasons, the most important being the properties of granite itself. Unlike cast iron, granite has undergone a long process of natural aging, eliminating internal stress. As a result, granite remains stable and does not warp over time, which is a critical factor for precision measurements.

1. Long-Term Stability

Granite’s natural aging process makes it one of the most stable materials for surface plates. Cast iron, on the other hand, can develop internal stresses over time, leading to deformation. A granite surface plate for sale offers long-term reliability and maintains its flatness for extended periods, making it ideal for precision work.

2. Resistance to Corrosion and Wear

Granite is highly resistant to corrosion, unlike cast iron, which can rust if not properly maintained. This makes granite a more durable option, especially in environments with fluctuating humidity and temperature. The resistance to wear means that granite surface plates last longer and maintain their accuracy even after extended use.

3. Accuracy Levels

Granite surface plates are available in various accuracy levels: 000, 00, 0, and 1. The higher the grade, the more precise the surface. These accuracy levels make granite the go-to choice for inspection, marking, and measuring in high-precision industries.

Benefits of a Granite Surface Plate with Stand

A granite surface plate with stand offers added convenience and stability. The stand ensures that the surface plate remains at an optimal working height, reducing the strain on workers and enhancing productivity. Additionally, the stand can be adjusted to maintain the level of the surface plate, which is crucial for accurate measurements.

1. Ergonomics

Working on a surface plate that’s positioned too low or too high can result in discomfort and affect the quality of work. A granite surface plate with stand allows you to position the plate at the ideal height for ergonomic efficiency, improving both worker comfort and output.

2. Improved Stability

The stand provides added stability by distributing the weight of the granite surface plate evenly. This minimizes vibrations or movements during use, which can impact measurement accuracy. For precision marking, inspection, and fabrication, a stable work surface is critical.

3. Mobility Options

Some stands come with wheels or casters, allowing you to move the granite surface plate around your workspace easily. This mobility is particularly useful in larger fabrication or inspection shops where flexibility is required.

The Role of Fabrication Tables in Precision Work

While fabrication tables are useful in industrial settings for general assembly, welding, and other tasks, they are not designed for precision work in the same way that granite surface plates are. Fabrication tables are typically made from steel or cast iron, and while they offer durability, they lack the stability and precision that granite provides.

1. Surface Precision

The primary difference between a fabrication table and a granite surface plate lies in the level of precision. Fabrication tables are designed for heavy-duty tasks but do not offer the flatness or accuracy required for detailed measurements and inspections. If your work demands precision down to the micron level, a granite surface plate for sale is your best option.

2. Durability vs. Precision

While fabrication tables are incredibly durable and resistant to heavy impacts, their surface can become scratched, dented, or deformed over time. These imperfections can affect the accuracy of your work. Granite surface plates, on the other hand, are not only more resistant to wear but also maintain their flatness and precision over long periods of use.

3. Applications

Fabrication tables are perfect for general industrial use, such as welding, cutting, and assembly. However, when it comes to tasks that require meticulous precision, such as calibration or inspection, granite surface plates are the tool of choice.

Choosing the Right Granite Surface Plate for Sale

When selecting a granite surface plate, there are several factors to consider to ensure you choose the right one for your needs.

1. ขนาด

The size of the granite surface plate you need depends on the scale of your work. Smaller plates are suitable for detailed inspection tasks, while larger plates are required for marking or inspecting larger components.

2. Accuracy Level

As mentioned earlier, granite surface plates come in different accuracy levels: 000, 00, 0, and 1. For the highest precision, choose a plate with an accuracy of grade 000 or 00. If your work requires slightly less accuracy, a grade 0 plate will suffice.

3. Accessories

Consider purchasing a granite surface plate with stand for ergonomic efficiency and added stability. You may also want to invest in accessories such as protective covers to shield the surface plate from dust and other contaminants when not in use.

4. Budget

While granite surface plates tend to be more expensive than cast iron, they are a long-term investment. The durability, precision, and low maintenance costs make them a more cost-effective solution over time.

Why Invest in a Granite Surface Plate?

In industries where precision is non-negotiable, investing in a granite surface plate is a must. Whether you’re involved in manufacturing, engineering, or quality control, the stability, durability, and accuracy offered by granite far exceed that of cast iron or steel alternatives. The natural properties of granite, combined with advanced manufacturing techniques, ensure that granite surface plates remain flat and accurate for years, making them an essential tool in any precision-focused workspace.

From the granite surface plates for sale to the versatility offered by fabrication tables, making the right choice depends on your specific needs. However, if accuracy, stability, and long-term performance are your priorities, the granite surface plate with stand is the superior choice.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion Controlข่าวAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial Useข่าวAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline Clogsข่าวAug.05,2025

-

The Importance of Regular Calibration for Master Ring Gagesข่าวAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in Manufacturingข่าวAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow Controlข่าวAug.05,2025

สินค้าที่เกี่ยวข้อง