ธ.ค. . 10, 2024 00:20 Back to list

Understanding Pin Gauge Sizes for Precision Measurement and Tooling Applications

Understanding Pin Gauge Sizes A Comprehensive Overview

Pin gauges are essential tools used in various engineering and manufacturing applications to measure hole sizes, diameters, and ensure the proper fit of parts. These cylindrical tools come in a range of sizes, allowing engineers and technicians to meet the precise specifications required in their work. This article will delve into pin gauge sizes, their applications, and why they are crucial in maintaining quality standards in manufacturing processes.

What Are Pin Gauges?

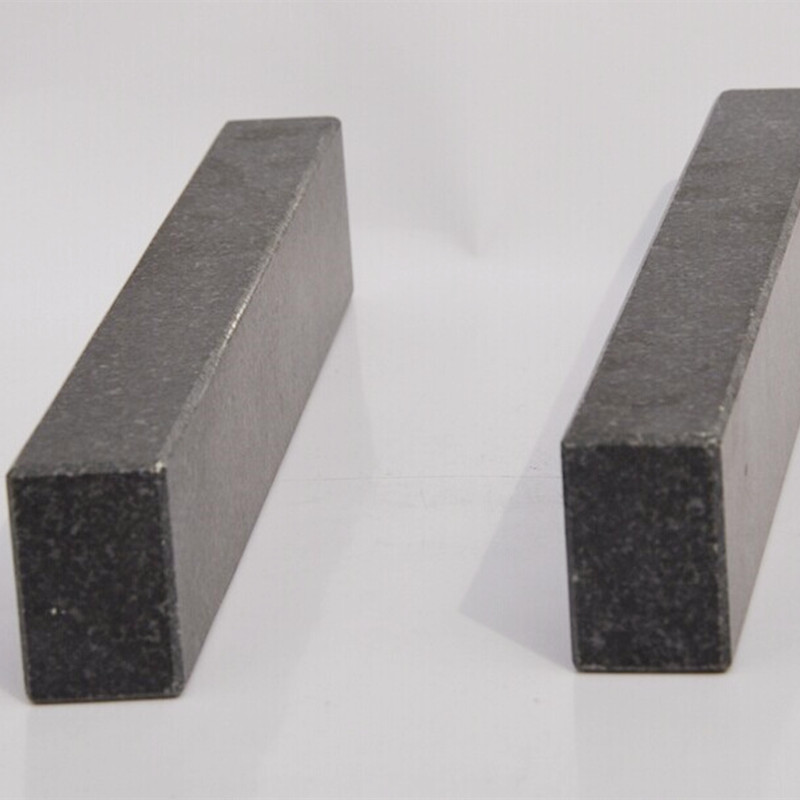

Pin gauges, also known as pin measuring plugs, are precision tools that consist of a straight, cylindrical pin manufactured to exact dimensions. They are typically made from high-strength materials such as steel or carbide, which provide durability and resistance to wear. The ends of the pins are often ground to enhance accuracy and surface finish. Pin gauges are commonly used in the inspection of holes, slots, and other dimensional measurements where precision is critical.

Types of Pin Gauges

Pin gauges are generally categorized into two primary types fixed pin gauges and adjustable pin gauges

.1. Fixed Pin Gauges These are available in a range of standardized sizes, each designed to fit a specific diameter. They are an economical choice for many applications and are widely used due to their simplicity and reliability. Fixed pin gauges are often used in quality control processes to ensure that produced parts conform to specified tolerances.

2. Adjustable Pin Gauges Unlike fixed pin gauges, adjustable pin gauges can be set to a range of sizes. These are highly versatile tools that allow for custom measurements without the need to keep an extensive inventory of fixed-size pins. They are particularly useful in applications where components may vary slightly in size.

pin gauge sizes

Pin Gauge Sizes and Standards

Pin gauges are available in numerous sizes, typically from 0.5 mm (0.020 inches) to 25 mm (1 inch) or more, depending on the manufacturer's standards. The specific sizes often adhere to international standards such as ISO, ANSI, or ASME, which define the tolerances and specifications for these measuring devices.

The standard increment for pin sizes is usually set at 0.01 mm or 0.001 inches, ensuring that users have an extensive range of options to measure various diameters accurately. When selecting pin gauges, it is crucial to consider the application requirements, including the tolerance levels of the parts being inspected.

Importance of Pin Gauge Sizes in Manufacturing

The significance of pin gauge sizes in manufacturing cannot be understated. They serve as a benchmark for quality assurance, helping to verify that parts fit together correctly, which is essential in assembly processes. By using pin gauges, manufacturers can significantly reduce the likelihood of issues arising from improperly sized components, such as excessive wear, misalignment, or failure during operation.

Moreover, pin gauges play a vital role in maintaining consistency across production runs. Regular inspections using these gauges provide critical feedback to operators, allowing for necessary adjustments in machining processes to achieve desired dimensions and tolerances.

Conclusion

In conclusion, pin gauge sizes are fundamental tools in the realm of precision measurement. Understanding the different types of pin gauges and their respective sizes is crucial for anyone involved in engineering or quality control processes. By utilizing pin gauges effectively, industries can assure high-quality production standards, thereby enhancing reliability and performance in a wide array of applications. As manufacturing continues to evolve, the role of precision measurement tools like pin gauges will remain indispensable in achieving excellence in engineering and production practices.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS