พ.ย. . 18, 2024 14:21 Back to list

HighPrecision Iron Surface Plates for Accurate Measurements and Quality Assurance

The Importance of Iron Surface Plates in Precision Measurement

In the realm of manufacturing and engineering, precision is paramount. One of the unsung heroes in achieving accuracy in measurements is the iron surface plate. These flat, heavy plates are critically important in the setup and alignment of various measuring instruments, providing a stable reference plane for inspections and calibrations.

Iron surface plates, traditionally made from cast iron, are prized for their rigidity and resistance to deformation. The material has excellent vibration-dampening properties, which is particularly beneficial in environments where external disturbances can affect precision measurements. Typically ranging in size and thickness, these plates can be found in machine shops, laboratories, and manufacturing facilities, serving as a foundational element in the measurement process.

One of the primary uses of an iron surface plate is as a reference surface for precision measuring tools such as dial indicators, height gauges, and calipers. By placing a workpiece on the surface plate, technicians can inspect it for flatness, height, and dimensional accuracy. The high level of flatness achievable with these plates makes them ideal for machining and inspection applications, where minute deviations can lead to significant quality control issues.

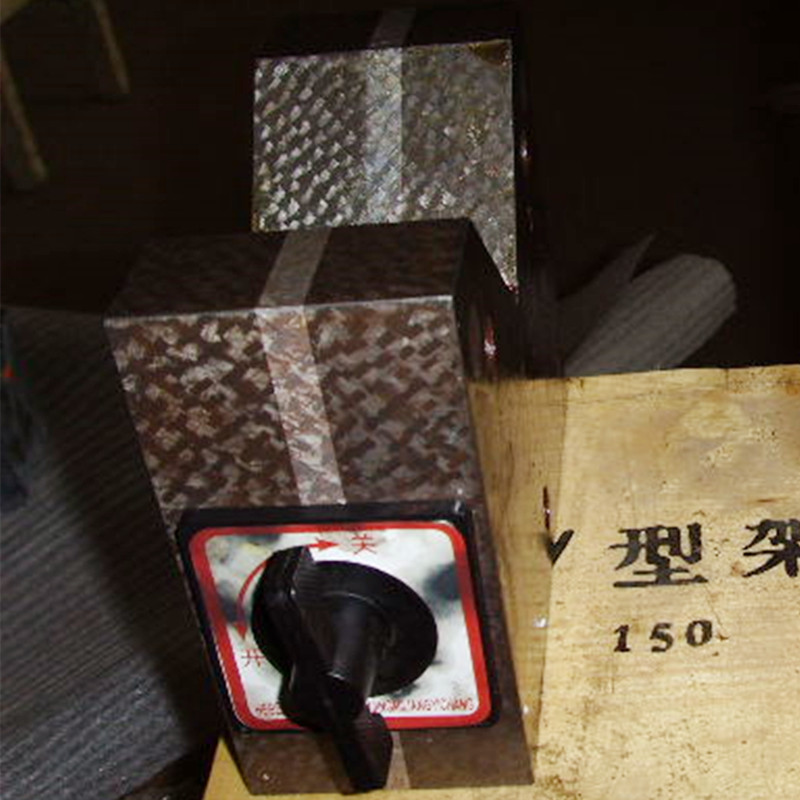

iron surface plate

Moreover, iron surface plates come with a variety of finishes, including ground and lapped surfaces

. The lapped surfaces provide an even finer level of accuracy, often required in applications involving high-precision instruments. Maintenance of these plates is crucial; regular cleaning and periodic calibration ensure that they remain accurate and effective over time.The durability of cast iron makes these plates a long-term investment in ensuring measurement accuracy. Unlike other materials, iron surface plates do not easily deform under pressure, maintaining their flatness even after years of use. However, they should be handled with care to avoid chipping or scratching, which could compromise their effectiveness.

Another benefit of iron surface plates is their relatively low cost compared to alternative high-precision surfaces made from granite or other advanced materials. While granite plates are also popular for their stability and precision, cast iron plates offer a practical solution for many manufacturing settings where budget constraints are a factor.

In conclusion, the role of iron surface plates in precision measurement cannot be overstated. They provide a stable, accurate reference point for a wide array of measurement and inspection tasks, essential for maintaining quality standards in manufacturing. By investing in high-quality iron surface plates and ensuring their correct maintenance, industries can significantly enhance their productivity and accuracy, ultimately leading to better product outcomes and customer satisfaction.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS