నవం . 01, 2024 19:50 Back to list

Specifications and Applications for DN80 Gate Valve in Industrial Settings

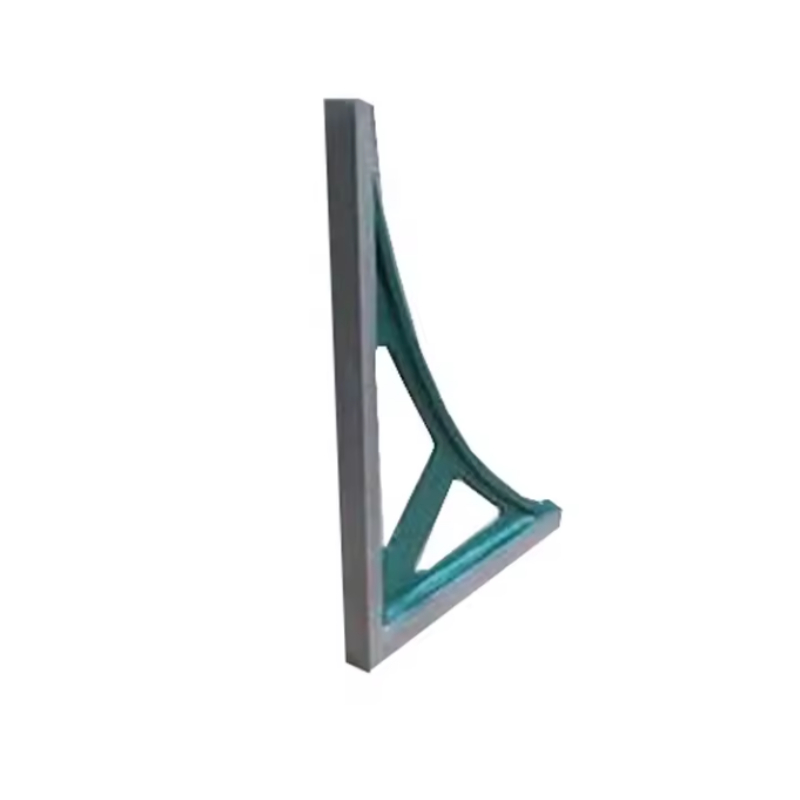

Understanding the Gate Valve DN80 A Comprehensive Overview

When it comes to fluid control in various industrial applications, the gate valve is one of the most popular types of valves used today. Specifically, the DN80 gate valve holds a significant position due to its size and versatility. DN, or Diameter Nominal, references the valve's nominal size in millimeters; thus, DN80 indicates a valve with a diameter of 80 millimeters.

What Is a Gate Valve?

A gate valve is primarily designed to allow or obstruct the flow of fluid. Unlike other valve types, such as globe valves or ball valves, gate valves are either fully open or fully closed. They are known for their exceptional sealing ability and minimal flow resistance when fully open. This feature makes them ideal for applications where a straight-line flow of fluid is necessary.

Design and Construction

The gate valve DN80 typically features a steel or cast iron body, with various internal components that can vary depending on the application. The internal mechanism consists of a gate or wedge that moves up and down, driven by a handwheel or actuator. When the handwheel is turned, the gate moves down into the flow path to close the valve or rises to open it.

The design of the DN80 gate valve ensures durability and reliability. Many are equipped to handle high pressures and can withstand varying temperatures, making them suitable for both cold water services and hot applications, such as steam and oil transport.

Applications of DN80 Gate Valves

gate valve dn80

The DN80 gate valve finds application across a wide range of industries, including waterworks, wastewater treatment, oil and gas, and power generation. In water distribution systems, these valves help manage the flow of water between different sections of pipelines. In the oil and gas industry, they are used to control the flow of crude oil or natural gas in various processing stages.

One of the key advantages of using a DN80 gate valve is its ability to provide a tight seal. This capability prevents fluid leakage, which is essential for safety and environmental concerns. Furthermore, when the valve is fully open, it presents minimal resistance to fluid flow, thereby preserving system efficiency.

Maintenance and Operation

Like any mechanical device, the DN80 gate valve requires routine maintenance to ensure longevity and optimal performance. Operators should regularly check for signs of wear, corrosion, or any leakage. It’s essential to exercise the valve periodically to prevent it from seizing or becoming stuck in the closed position.

In terms of operation, the valve should always be opened and closed gradually to avoid sudden pressure fluctuations that could damage the valve seat or associated pipework.

Conclusion

In conclusion, the DN80 gate valve is an indispensable component in various industrial systems. Its robust design, reliability, and effective flow control make it a preferred choice among engineers and operators alike. Understanding the features and maintenance requirements of the DN80 gate valve is essential for anyone involved in fluid management, ensuring both efficient operation and safety in any industrial setting. Whether it’s controlling water flow or managing hydrocarbons, the DN80 gate valve stands out as a critical element in the engineering and operational toolkit.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS