నవం . 08, 2024 04:07 Back to list

Precision Dial Bore Gauge Set for Accurate Measurement of Cylinder Diameters and Internal Sizing

Understanding Dial Bore Gauge Sets A Comprehensive Guide

When it comes to precision measurement in engineering and mechanical applications, a dial bore gauge set is an essential tool for any technician or engineer. This instrument is designed to measure the internal diameter of holes, ensuring that they meet strict specifications and tolerances crucial in various industries, from automotive to aerospace. In this article, we will delve into the workings, applications, and importance of dial bore gauge sets.

What is a Dial Bore Gauge?

A dial bore gauge consists of a measuring head that houses a dial indicator, a set of interchangeable contacts, and a shaft that can be adjusted to fit different bore sizes. This tool operates on the principle of comparative measurement, where the gauge is inserted into the bore and expanded until it contacts the walls of the hole at both sides. The dial indicator then provides a precise reading of the bore’s diameter by measuring the distance the gauge moves.

Components of a Dial Bore Gauge Set

1. Dial Indicator The heart of the gauge, this component translates the mechanical movement of the gauge into a readable dial measurement, usually calibrated in micrometers or thousandths of an inch.

2. Expandable Rod This is the part that extends into the bore. It can be adjusted based on the size of the hole being measured.

3. Interchangeable Contacts These are crucial for taking measurements at various depths and diameters. Different shapes and sizes can accommodate different bore configurations.

4. Calibration Standards To ensure accurate readings, calibration standards are sometimes included in a dial bore gauge set, allowing users to check and adjust the accuracy of their measurements.

How to Use a Dial Bore Gauge

Using a dial bore gauge is relatively straightforward, but accuracy lies in technique

2. Setting Up Select the appropriate contact size based on the bore diameter. Insert the expandable rod into the bore, ensuring it doesn’t touch the walls initially.

dial bore gauge set

3. Adjusting the Gauge Slowly expand the gauge until it makes contact with the bore walls on both sides. Use the fine adjustment feature available in many sets for precise settings.

4. Reading the Measurement The dial indicator will provide you with a reading. It is essential to take multiple measurements at different points along the bore to account for any irregularities or tapering.

Applications of Dial Bore Gauge Sets

Dial bore gauge sets are widely used across various industries

- Automotive In car manufacturing and repair, these gauges are used to measure cylinder bores, ensuring that they are within specifications for performance and safety.

- Aerospace Precision is critical in aerospace components, making dial bore gauges vital for measuring fuel lines, bolt holes, and structural openings.

- Manufacturing Many manufacturing processes require tight tolerances, and dial bore gauges help ensure that machinery and components meet those requirements.

- Quality Control In any production line, quality control is essential. Using dial bore gauges helps maintain the integrity of products by ensuring proper dimensions.

Importance of Accuracy

Accuracy is of utmost importance when measuring bores. A slight deviation can lead to significant issues down the line, including mechanical failure, safety hazards, or costly rework. Therefore, investing in a high-quality dial bore gauge set is a wise decision for anyone involved in precision engineering.

Conclusion

In summary, a dial bore gauge set is a fundamental tool for anyone involved in measurement and machining in various industries. Understanding its components and how to use it effectively can significantly impact the quality of work and precision measurements. Whether you are measuring engine components, ensuring structural integrity in aerospace applications, or simply performing routine quality checks in a manufacturing environment, a reliable dial bore gauge is an indispensable asset. By mastering this tool, professionals can achieve the high standards of accuracy and quality required in modern engineering and manufacturing processes.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

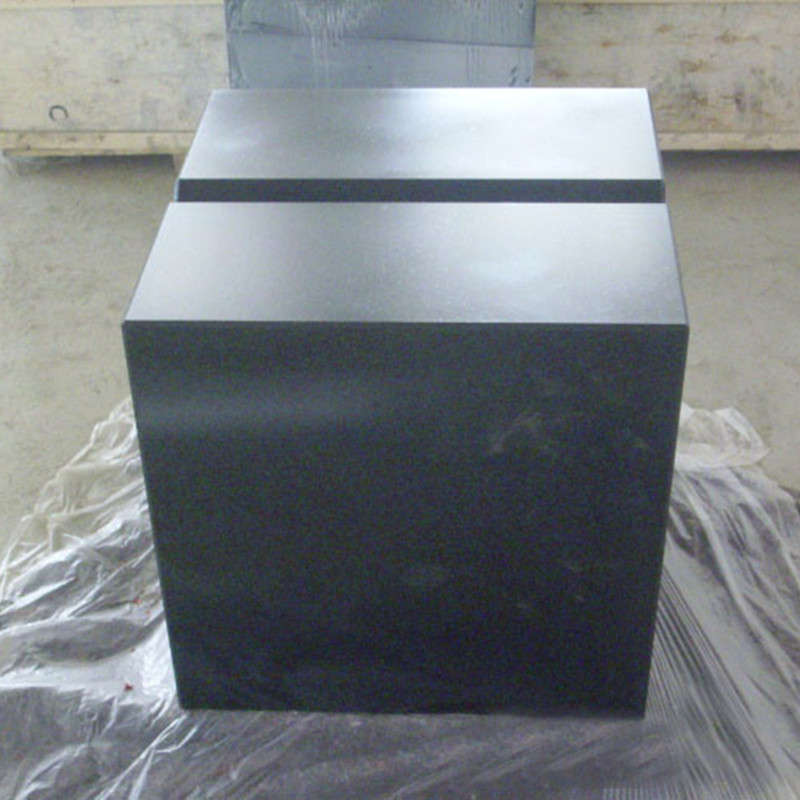

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS