நவ் . 05, 2024 23:19 Back to list

Understanding the Applications of Taper Ring Gauges in Precision Measurements

Understanding the Taper Ring Gauge Its Uses and Importance

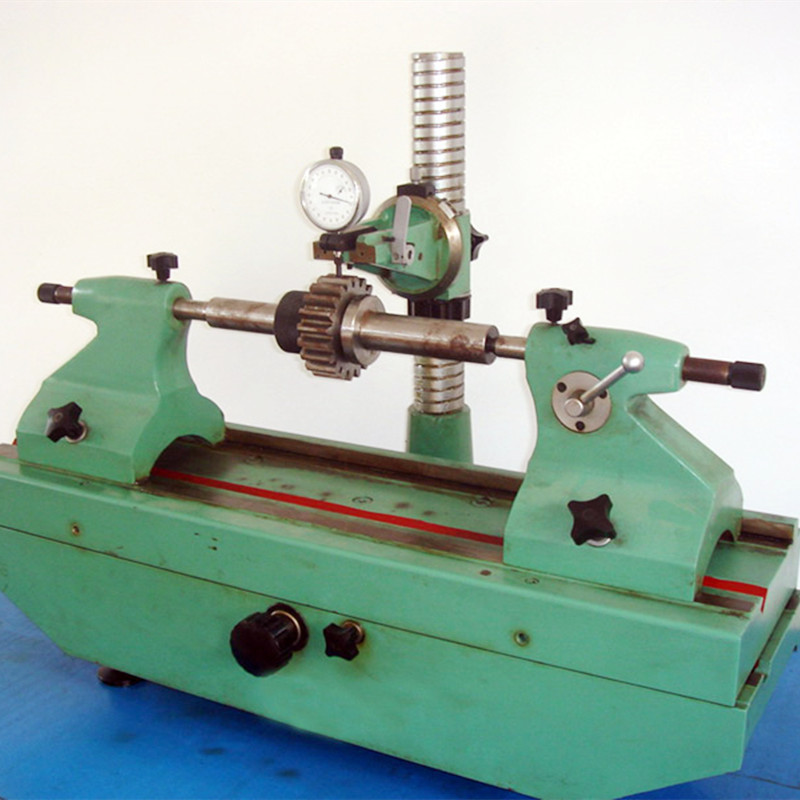

A taper ring gauge is an essential tool used primarily in manufacturing and engineering fields to measure the dimensions of tapered components. This specialized gauge is engineered to verify the accuracy of the taper of holes and shafts and to ensure that machined parts meet specific tolerances and standards.

What is a Taper Ring Gauge?

A taper ring gauge is a precision instrument designed with a conical shape that allows it to gauge the taper of various components. The gauge typically features precise angles on its tapered surfaces to allow for accurate measurements of the taper's depth and diameter. It serves as a reliable standard against which the dimensions of the workpiece can be checked. Taper ring gauges are often made from high-grade materials like steel or carbides to maintain durability, resistance to wear, and decrease the likelihood of distortion over time.

Uses of Taper Ring Gauges

1. Quality Control In manufacturing, ensuring the quality of machined parts is crucial. Taper ring gauges are widely used in quality control processes to inspect the taper of holes and shafts. They help in identifying defects and ensuring that the components fit together correctly, enhancing the reliability of mechanical assemblies.

2. Dimensional Inspection Taper ring gauges are used to measure the accuracy of a workpiece's dimensions. They can confirm whether a component meets the specified tolerances outlined in engineering drawings. This is especially important in industries such as aviation, automotive, and precision machinery, where even slight deviations can lead to catastrophic failures.

taper ring gauge is used for

3. Tool Calibration These gauges can also be employed to calibrate other measuring instruments. By using a taper ring gauge as a reference standard, manufacturers can ensure that their equipment is measuring accurately over time and usage. This contributes to overall production efficiency and reduces the likelihood of errors.

4. Assembly Verification In assembly processes, taper ring gauges can be used to check that coupled parts align properly. This reduces the risk of misalignment that could lead to operational failures or increased wear on the components.

Importance of Taper Ring Gauges

The importance of taper ring gauges cannot be overstated. By providing a means to measure and verify the taper of components, they play a critical role in ensuring precision. In sectors where exact specifications are paramount, these gauges help manufacturers maintain high standards of quality control. This leads to decreased production costs, as rework and scrap rates are minimized, and an enhancement in product integrity and reliability.

Moreover, with the rise of automated and precision manufacturing, the reliance on accurate measurements has increased. Taper ring gauges meet this demand, providing manufacturers with a trustworthy solution for gauging taper angles and other dimensions with high accuracy.

Conclusion

In conclusion, taper ring gauges are pivotal tools in the world of manufacturing and engineering. Their ability to measure and verify tapered dimensions ensures that components are manufactured with precision, enhancing the overall reliability and safety of mechanical systems. As industries continue to evolve and demand higher standards of quality, the role of taper ring gauges will only become more significant, underscoring their importance in achieving excellence in production processes.

-

The Role of Cast Iron T Slot Plates in RoboticsNewsMay.12,2025

-

The Importance of Parallel Rulers in Mechanical EngineeringNewsMay.12,2025

-

Heavy-Duty Applications for Granite Surface Plate for SaleNewsMay.12,2025

-

Cast Iron Y Strainer: A Reliable Solution for Dirty FluidsNewsMay.12,2025

-

Boosting Workshop Productivity Using Granite BlocksNewsMay.12,2025

-

Water Control Valves: Essential Components for Fluid RegulationNewsMay.08,2025

Related PRODUCTS