டிசம்பர் . 05, 2024 11:29 Back to list

strainer type y

Understanding Strainer Types A Comprehensive Guide

Strainers are essential components in different industries, designed to filter out unwanted particles from liquids or gases to ensure smooth operation and longevity of equipment. Among the various types of strainers available, the Y-strainer is one of the most widely used due to its efficiency and compact design. In this article, we will delve into the characteristics, benefits, applications, and considerations of the Y-strainer type to help you understand its significance in various applications.

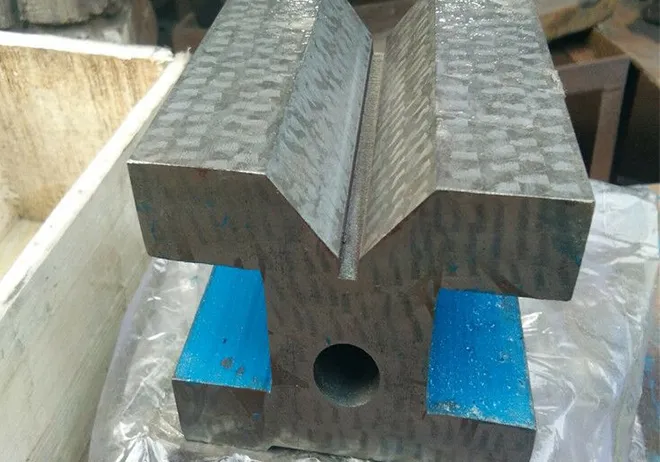

What is a Y-Strainer?

The Y-strainer gets its name from its unique shape, resembling the letter “Y.” This design allows for a symmetrical flow path, enabling liquids or gases to enter the strainer, filter through a mesh or perforated screen, and exit through a separate outlet. Typically constructed from robust materials such as stainless steel, brass, or cast iron, Y-strainers are engineered to withstand high-pressure and temperature applications.

Characteristics of Y-Strainers

1. Shape and Design The Y-shape allows for a more compact installation in tight spaces, making it ideal for various piping systems. 2. Filtering Capability Y-strainers come equipped with different mesh sizes or perforations, allowing various levels of filtration depending on application requirements. They can effectively remove debris and contaminants from liquids and gases.

3. Maintenance Y-strainers are designed for ease of maintenance. They often feature a removable screen, which can be accessed for cleaning without needing to remove the entire strainer from the pipeline.

4. Flow Direction The configuration allows for liquid or gas to flow in a straight line, minimizing pressure drops across the system.

Benefits of Using Y-Strainers

- Protection of Equipment By effectively filtering out particles, Y-strainers help in protecting pumps, valves, and other equipment downstream from damage caused by debris.

- Versatility Y-strainers are used in a wide range of applications, spanning from water treatment facilities to chemical processing, oil and gas, and HVAC systems.

- Cost-Effectiveness With their ability to prolong the life of equipment and reduce maintenance costs, Y-strainers can be a cost-effective solution for many industries.

- Compact Size Their design allows for installation in areas where space is limited, providing flexibility in system design.

Applications of Y-Strainers

strainer type y

Y-strainers can be found in various industries, providing filtration solutions across numerous applications

1. Water Treatment Used to protect pumps and other equipment from suspended sediments and debris in water sources.

2. Oil and Gas Common in pipelines to filter out solid contaminants from crude oil and natural gas, ensuring efficient transport and processing.

3. Chemical Processing Help to prevent damage to sensitive equipment by removing solids from chemicals during the production phase.

4. HVAC Systems Employed to protect cooling and heating systems by filtering particulates from water and refrigerants.

5. Food and Beverage Ensure that production lines remain clear of contaminants, maintaining product quality and safety.

Considerations When Choosing a Y-Strainer

When selecting a Y-strainer for your application, consider the following factors

- Material Depending on the medium being filtered, select a material that can withstand the specific chemical properties and temperature conditions.

- Filtration Size Choose an appropriate mesh size that will effectively filter out potential contaminants without compromising flow rates.

- Installation and Space Evaluate the available space in your system and ensure the chosen Y-strainer fits properly.

- Maintenance Needs Consider how easy it is to access the strainer for cleaning and maintenance, especially in larger systems.

Conclusion

In conclusion, Y-strainers play a pivotal role in maintaining the integrity of various industrial systems by filtering out unwanted particles from liquids and gases. Their unique design, combined with their versatility and cost-effectiveness, makes them an invaluable component in many applications. Understanding the characteristics, benefits, applications, and selection considerations of Y-strainers is crucial for making informed decisions that will ensure the efficiency and longevity of industrial systems. Whether you're involved in water treatment, chemical processing, or HVAC applications, a Y-strainer can significantly contribute to the reliability and performance of your operations.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS