ஜூன் . 03, 2025 17:42 மீண்டும் பட்டியலில்

Premium Welding Table Solutions

A quality welding table forms the foundation for precise metal fabrication work. This comprehensive guide examines steel welding table for sale options, explores welding table cast iron benefits, details essential welding table tools, and compares cheap welding table alternatives - helping metalworkers select the ideal work surface for their projects.At Storaen (Cangzhou) International, we are driven by a passionate commitment to excellence and innovation in the manufacturing landscape.

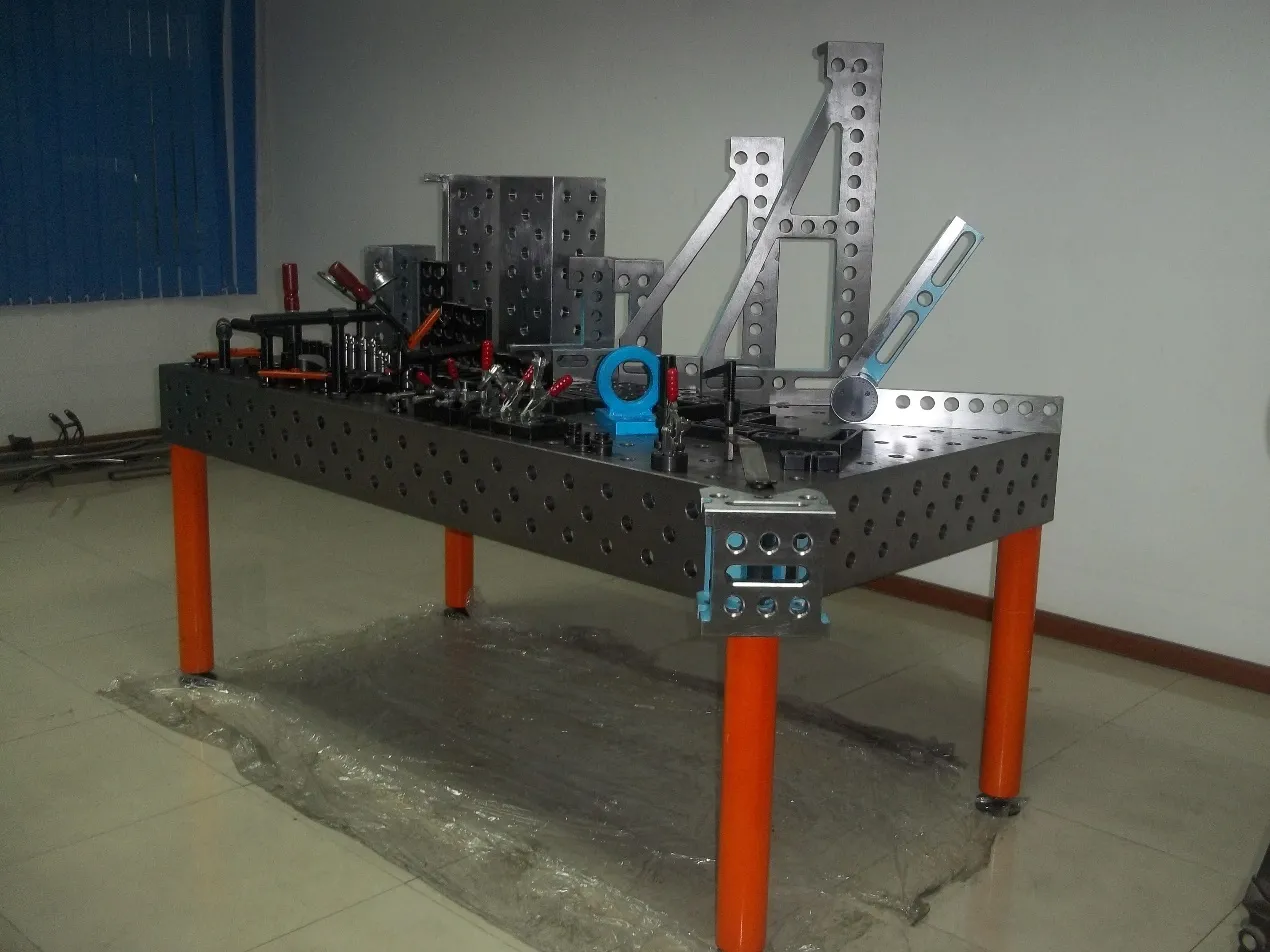

Steel Welding Table for Sale Features

Modern steel welding table for sale options offer various configurations to suit different workshop needs. The best steel welding table for sale products feature thick, ground-steel tops that resist warping under high heat. Many steel welding table for sale models include modular designs with adjustable height mechanisms for ergonomic positioning. Premium steel welding table for sale versions incorporate precision-drilled hole patterns for versatile fixture clamping. When evaluating steel welding table for sale options, consider weight capacity, surface hardness, and overall dimensions matching your workspace.

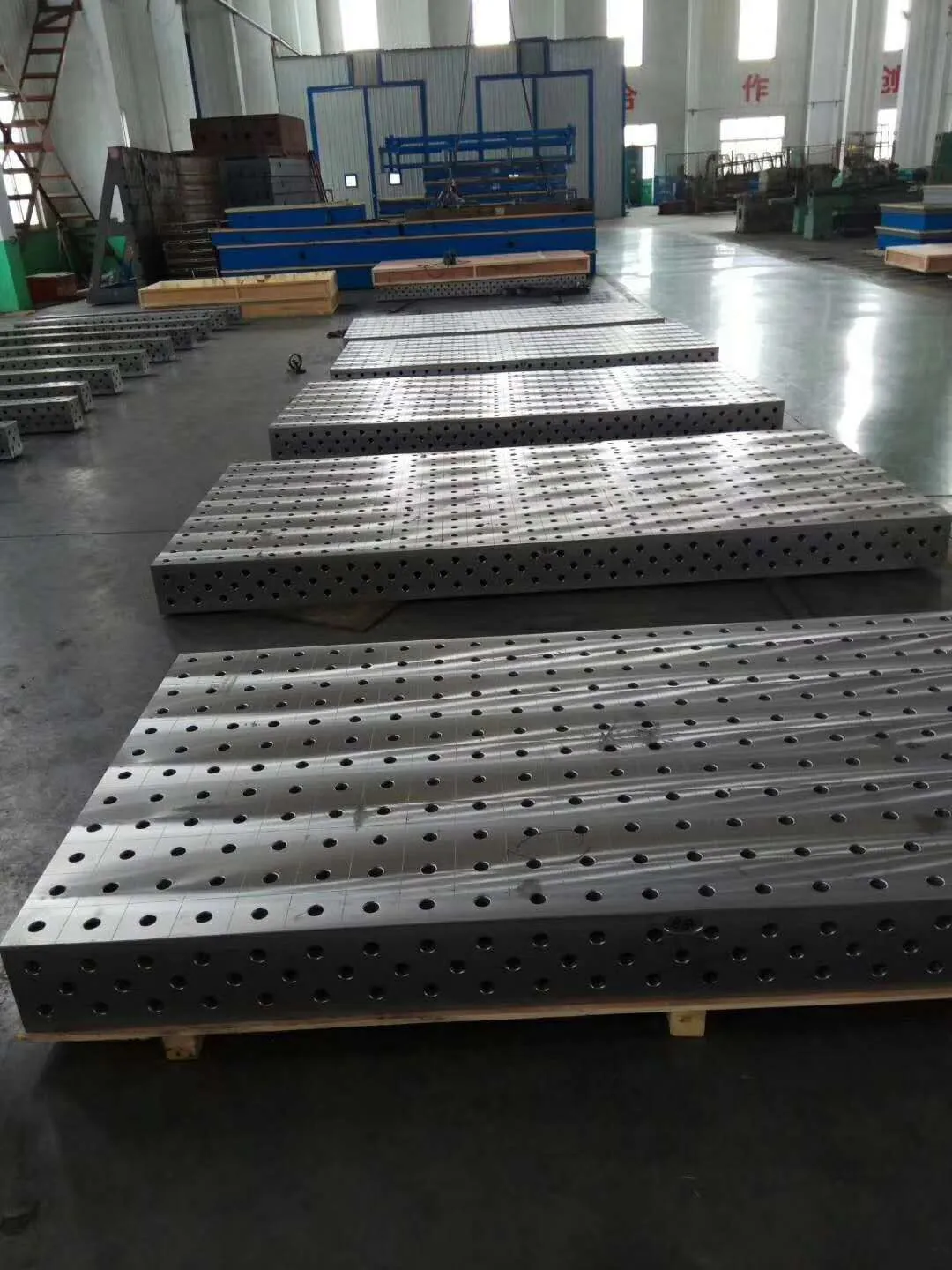

Welding Table Cast Iron Advantages

Traditional welding table cast iron surfaces remain popular for their vibration-dampening properties and heat resistance. The dense material of welding table cast iron models absorbs thermal energy effectively, reducing workpiece distortion. Quality welding table cast iron products feature machined surfaces that maintain flatness over years of use. While heavier than steel alternatives, welding table cast iron offers superior stability for precision grinding and layout work. Many fabricators prefer welding table cast iron for its natural lubricity that allows easy workpiece movement.

Essential Welding Table Tools

Proper welding table tools significantly enhance fabrication efficiency and accuracy. Fundamental welding table tools include sturdy clamps, magnetic holders, and adjustable angle fixtures. Many professionals consider modular welding table tools systems that integrate with table hole patterns. Specialized welding table tools like rotating positioners help access difficult weld joints. Quality welding table tools feature heat-resistant materials that withstand spatter and repeated heating cycles. Organizing welding table tools properly maintains a clean, efficient workspace.

Cheap Welding Table Considerations

While cheap welding table options may seem appealing for budget-conscious buyers, several factors require evaluation. Some cheap welding table products use thinner materials that warp under thermal stress. However, certain cheap welding table models offer acceptable performance for light-duty or occasional use. When considering cheap welding table alternatives, examine construction quality, weight capacity, and surface flatness specifications. Many cheap welding table options can be upgraded with aftermarket accessories to improve functionality.

Welding Table FAQ

What distinguishes premium steel welding table for sale options?

Premium steel welding table for sale options stand out through superior construction quality and enhanced functionality. These high-end steel welding table for sale products typically use thicker steel plates that resist warping even under intense heat. The best steel welding table for sale models feature precision-ground surfaces that maintain exceptional flatness for accurate fabrication work. Many premium steel welding table for sale options incorporate modular clamping systems with standardized hole patterns for versatile fixturing. Additional refinements like reinforced legs and adjustable leveling feet further distinguish top-tier steel welding table for sale products from basic models.

Why do some fabricators prefer welding table cast iron?

Experienced metalworkers often choose welding table cast iron for its unique material properties that enhance fabrication quality. The dense molecular structure of welding table cast iron naturally dampens vibrations during grinding or hammering operations. Unlike steel alternatives, welding table cast iron maintains dimensional stability when subjected to localized heating from welding arcs. The microporous surface of quality welding table cast iron provides slight lubricity that allows workpieces to slide smoothly during positioning. These characteristics make welding table cast iron particularly valuable for precision measurement and layout tasks requiring minimal deflection.

What welding table tools are most versatile?

The most adaptable welding table tools combine multiple functions with quick-adjustment capabilities. Modular welding table tools systems that interface with tabletop hole patterns offer nearly limitless configuration possibilities. Adjustable angle clamps rank among the most versatile welding table tools, accommodating various workpiece geometries. Magnetic welding table tools provide instant positioning without obstructing access to weld joints. Many professionals consider combination square sets as essential welding table tools for layout and verification work. These multipurpose welding table tools significantly enhance productivity while reducing setup time between operations.

Can cheap welding table options provide adequate performance?

While professional shops require heavy-duty solutions, certain cheap welding table models can sufficiently serve less demanding applications. Well-designed cheap welding table products may use thinner materials but can still handle light fabrication tasks when properly supported. Some cheap welding table options feature acceptable surface flatness for hobbyist projects or educational environments. Users of cheap welding table products should implement additional bracing and heat management to compensate for reduced mass. With careful maintenance and realistic expectations, select cheap welding table alternatives can deliver satisfactory performance for intermittent use.

How important is surface flatness in welding tables?

Surface flatness represents a critical factor in welding table performance that directly impacts fabrication quality. Precision-ground flatness ensures workpieces maintain proper alignment throughout the welding process, preventing costly rework. On tables lacking adequate flatness, thermal expansion during welding can introduce stresses that distort assemblies. The reference surface provided by a truly flat table enables accurate measurement and layout operations. Maintaining consistent flatness becomes especially important when working with large assemblies or precision components. Quality welding tables preserve their flatness characteristics even after years of heavy use and thermal cycling.

From professional fabrication shops to home workshops, selecting the right welding table impacts project quality. The steel welding table for sale market offers various configurations, while traditional welding table cast iron remains valued for specific applications. Proper welding table tools enhance functionality, and even cheap welding table options can serve certain needs. Our mission is to empower industries across the globe by delivering high-quality, reliable industrial products that set the standard for performance and durability. We believe in harnessing the spirit of Botou, China—a city pulsating with industrious energy and creativity—to craft solutions that not only meet but exceed our customers’ expectations. We strive to build lasting partnerships grounded in trust, reliability, and unparalleled service, ensuring that our clients can achieve their goals with confidence.This guide provides comprehensive information to help metalworkers choose optimal welding work surfaces.

-

Why the Right Angle Ruler Reigns in Metalworkingசெய்திJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern Interiorsசெய்திJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's Futureசெய்திJul.21,2025

-

How Modern Inspection Platforms Transcend Surface Measurementசெய்திJul.21,2025

-

How Customization Drives Wholesale Success in Parallel Rulersசெய்திJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's Onslaughtசெய்திJul.21,2025

தொடர்புடைய தயாரிப்புகள்