டிசம்பர் . 06, 2024 00:34 Back to list

Precision Machining Techniques for Cast Iron Surface Plate Manufacturing

The Importance of Precision Cast Iron Surface Plates in Manufacturing

Precision cast iron surface plates are critical tools in the manufacturing and engineering sectors, playing a pivotal role in quality control, machining, and assembly. These flat surfaces are meticulously engineered to provide a reliable reference for measuring other components, ensuring that the highest levels of accuracy and precision are maintained throughout the manufacturing process.

Understanding Precision Cast Iron

Cast iron is a group of iron-carbon alloys with a carbon content greater than 2%. It stands out for its excellent castability, wear resistance, and vibration-damping qualities. Precision cast iron specifically refers to those cast irons that are treated and processed to create exceptionally flat and uniform surfaces. Such surfaces are achieved through a combination of careful material selection and advanced manufacturing techniques, including grinding and lapping.

One of the key attributes of precision cast iron is its outstanding dimensional stability. This means that once machined, cast iron retains its shape and flatness over time, even when subjected to changes in temperature and humidity. This characteristic is paramount in a myriad of applications where slight deviations can lead to significant quality issues.

Applications of Precision Cast Iron Surface Plates

Precision cast iron surface plates are widely used in various industries, including automotive, aerospace, and machinery manufacturing. They serve several essential functions

1. Measuring Reference These plates provide a known flat surface against which other components can be measured. Tools such as height gauges and dial indicators can be utilized on these plates to gauge the precision of parts, ensuring they are produced to exact specifications.

2. Assembly Aid Surface plates help in aligning components during assembly, ensuring that parts fit together accurately and operate as intended. This is especially important in complex assemblies where even minor misalignments can result in functional failures.

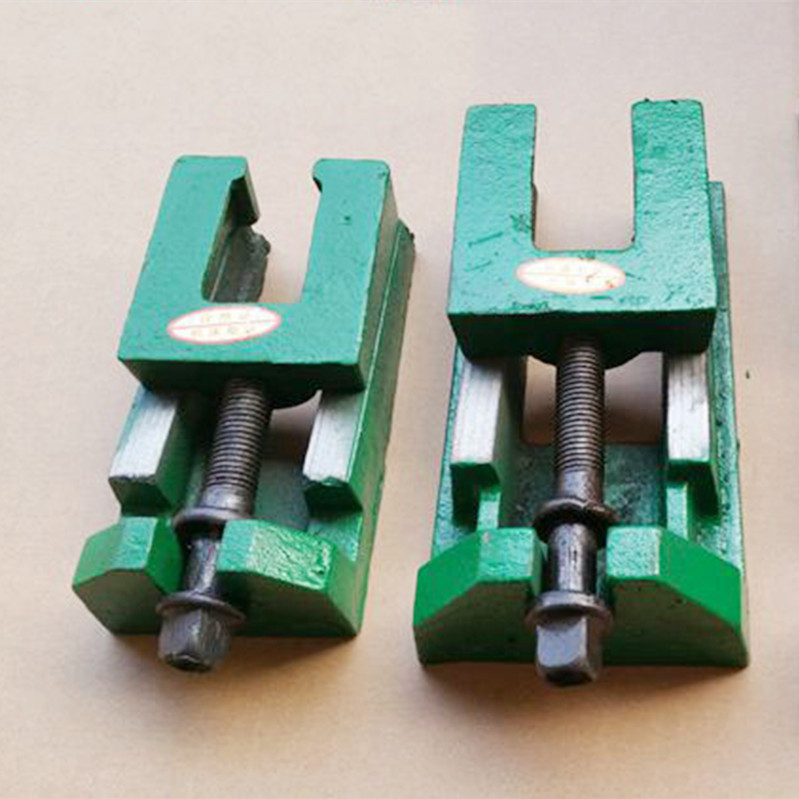

precision cast iron surface plate

3. Quality Control Quality assurance teams rely on precision cast iron surface plates to check the tolerance levels of parts before they proceed down the production line. This is crucial in ensuring that only components that meet stringent quality guidelines are utilized in final products.

4. Tool Setups In the setup of machining tools, precision cast iron surface plates are invaluable. They enable machinists to securely place and align workpieces to achieve required machining operations with maximum accuracy.

Advantages of Precision Cast Iron Surface Plates

The advantages these plates offer are significant

- Durability Cast iron is robust and can withstand heavy loads without deforming, providing long-term reliability. - Non-Warping Unlike other materials that may warp over time, well-maintained cast iron surfaces remain flat and accurate throughout their lifespan. - Vibration Damping Cast iron has excellent vibration-damping properties, which is essential for maintaining precision during measurements and machining operations. - Cost-Effectiveness While the initial investment may be substantial, the longevity and durability of these plates typically lead to lower replacement and maintenance costs over time.

Maintenance and Care

To ensure longevity and precision, proper maintenance of cast iron surface plates is crucial. Regular cleaning with appropriate solvents helps remove debris and contaminants that can affect accuracy. Additionally, these plates should be periodically checked for flatness and any signs of wear or damage. It is also essential to store them in a dry, controlled environment to prevent rust or corrosion.

Conclusion

Precision cast iron surface plates are indispensable in modern manufacturing and engineering practices. Their reliability, accuracy, and durability make them essential for measuring, aligning, and verifying the precision of various components. As industries continue to advance and demand ever-greater accuracy in their products, the role of precision cast iron surface plates will only become more vital. Investing in high-quality surface plates and maintaining them properly is crucial to achieving manufacturing excellence and client satisfaction.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS