Januari . 01, 2025 05:47 Back to list

Durable Stainless Steel Surface Plate for Accurate Measurement and Inspection Tasks

Iron Surface Plates Essential Tools in Precision Engineering

Iron surface plates are fundamental components in the field of precision engineering and metrology. These flat, rigid plates made of cast iron provide a stable and accurate reference surface for various applications, including inspection, calibration, and assembly of mechanical parts. Their importance cannot be overstated, as they serve as the backbone of quality control in manufacturing processes.

The primary purpose of an iron surface plate is to provide a perfectly flat and stable working surface. This flatness is vital for a variety of measuring instruments and tools. Engineers and machinists rely on these plates to ensure that measurements taken during various stages of production are accurate and repeatable. The flatness of the surface helps eliminate any errors that could arise from the workpiece not being properly aligned or leveled. Consequently, the use of iron surface plates is a critical step in achieving high standards of quality assurance.

Made from high-quality cast iron, these plates exhibit remarkable stability and durability. Cast iron is known for its excellent wear resistance, making these plates suitable for heavy-duty applications. Moreover, they can withstand significant loads without warping or deforming, which is particularly important in industrial environments where heavy machinery is prevalent. Iron surface plates are often designed with a specific thickness and weight to enhance their stability and performance.

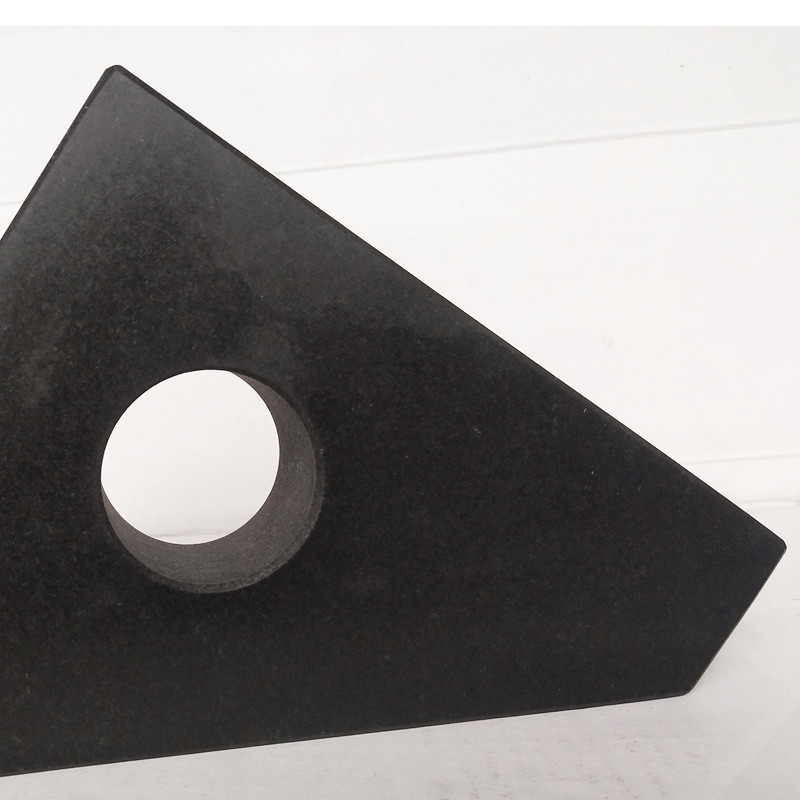

iron surface plate

In addition to their physical properties, iron surface plates are often finished with a high degree of precision. Techniques such as hand scraping can be employed to achieve the desired level of flatness and surface finish. This meticulous process ensures that the plates meet the strict standards required for accurate measurements. Some manufacturers may also use advanced machining techniques like CNC milling to produce these plates, further enhancing their precision.

Another essential feature of iron surface plates is their versatility. They can be used in conjunction with a wide range of measuring instruments, including dial indicators, micrometers, and gage blocks. This adaptability makes them suitable for various industries, including automotive, aerospace, and manufacturing. Iron surface plates can serve as inspection beds for checking the flatness of components, evaluating the dimensions of parts, and even aiding in the calibration of measuring tools.

Moreover, the maintenance of these plates is relatively simple. Regular cleaning and periodic checking for flatness can help extend their lifespan and ensure continued accuracy. In situations where a plate shows signs of wear, techniques like resurfacing can restore its flatness and functionality, making them a long-term investment for any workshop or manufacturing facility.

In conclusion, iron surface plates are indispensable tools in the realm of precision engineering. Their ability to provide a reliable and flat reference surface makes them essential for accurate measurements and quality control. With their robust construction and versatility, they are well-equipped to meet the demands of various industries. As precision engineering continues to evolve, the significance of iron surface plates will undoubtedly remain, solidifying their status as a cornerstone in the quest for excellence in manufacturing processes.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS