Novemba . 09, 2024 21:00 Back to list

Exploring the Significance of Gauges in Various Applications and Industries

Understanding Gauges An Essential Tool for Precision and Measurement

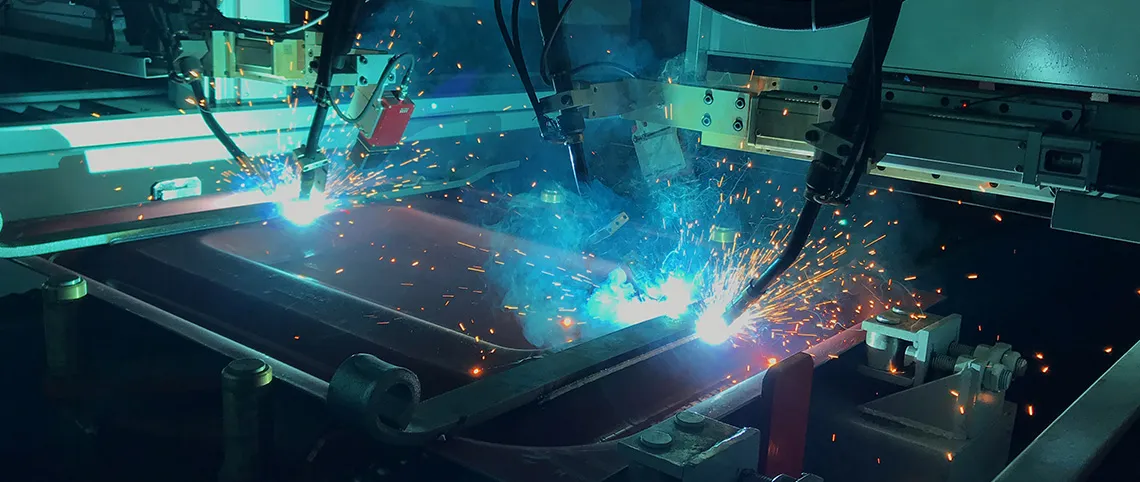

In various fields, from engineering and manufacturing to HVAC and automotive industries, precision and accuracy are paramount. One of the essential tools that ensure these qualities in measurement is the gauge. A gauge, in its simplest form, is a device or instrument used to measure the magnitude, amount, or contents of something. It plays a critical role in maintaining standards and ensuring that products, systems, and processes meet specified criteria. This article will explore the different types of gauges, their significance, and their applications in various industries.

Types of Gauges

Gauges come in various forms, each designed for specific applications. Some of the most common types include

1. Mechanical Gauges These include dial gauges, analog gauges, and pressure gauges. They utilize mechanical components like springs and levers to measure physical quantities. For instance, a pressure gauge measures the pressure of gases or liquids and displays the reading on a dial.

2. Electronic Gauges With advancements in technology, electronic gauges have gained prominence. These devices provide more precise readings and often come with digital displays. They can measure temperature, humidity, and pressure, converting these measurements into electronic signals.

3. Calipers and Micrometers These tools are crucial for measuring the dimensions of objects. Calipers can measure the external and internal dimensions of an object, while micrometers offer more precision, measuring minute distances or thicknesses.

4. Thickness Gauges These are used to measure the thickness of materials, such as coatings or films. They are essential in industries like automotive and manufacturing, where thickness impacts quality and performance.

5. Feeler Gauges Used primarily in mechanical settings, feeler gauges consist of a series of thin metal blades of varying thicknesses and are used to measure gap widths or clearance between surfaces.

gauge

Importance of Gauges

The significance of gauges cannot be understated. They ensure that products and processes remain within the defined tolerances, thereby maintaining quality and safety. For instance, in the automotive industry, gauges are crucial in ensuring that components like brake systems operate within acceptable limits. Accurate measurements prevent malfunctions that could lead to accidents, making gauges invaluable in safeguarding lives.

In the manufacturing sector, gauges play a vital role in quality control. They help in the assessment of raw materials, in-process components, and finished products. By utilizing gauges, manufacturers can detect deviations from specifications early in the production process, minimizing waste and reducing costs. This iterative check-and-balance system helps maintain high standards and facilitates continuous improvement.

Applications Across Industries

Gauges are used across numerous industries with incredible versatility. In the construction sector, for instance, they help ensure that materials meet structural integrity standards. A thickness gauge may be used to confirm that steel beams are within required limits, while moisture gauges can measure humidity levels in concrete to ensure proper curing.

In the healthcare industry, precision is critical. Medical devices, such as blood pressure monitors, rely on accurate gauge readings to provide vital health information. The accuracy of these gauges can have a direct impact on patient care and treatment outcomes.

The aerospace industry employs a range of gauges to ensure safety and performance standards in aircraft components. From measuring stress and strain to monitoring fuel pressure, gauges are integrated into multiple systems, reflecting their crucial importance in safety-critical applications.

Conclusion

In conclusion, gauges are indispensable tools across various sectors, providing precision and accuracy in measurement. Whether mechanical or electronic, these instruments ensure that products and processes comply with stringent quality standards, reducing risks and enhancing safety. As technology continues to evolve, the capabilities of gauges will undoubtedly expand, further solidifying their role in industries that demand meticulous attention to detail. Understanding and utilizing gauges effectively can lead to significant improvements in quality and efficiency, reinforcing their essential place in modern engineering and manufacturing practices.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS