Februari . 12, 2025 09:10 Back to list

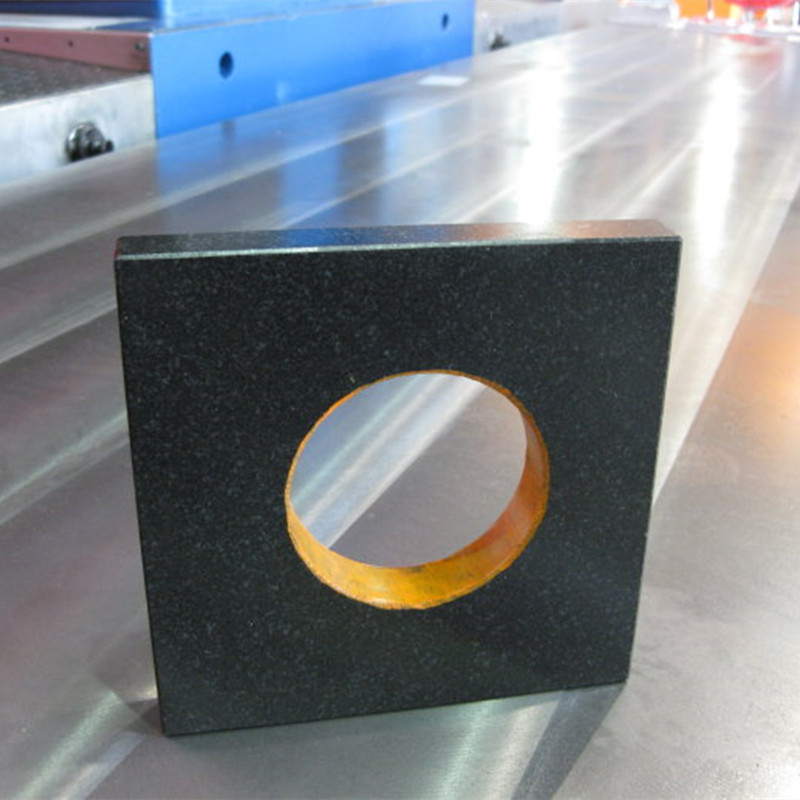

check valve assy

Understanding the Importance of a 100mm Check Valve A Comprehensive Guide

Installation and Maintenance Insights Correct installation is pivotal for the effective operation of a 100mm check valve. Positioning and alignment must be precise, as even minor misalignments can lead to inefficient operation or failures. It is often recommended to have an experienced technician oversee the installation process. Periodic maintenance should also be prioritized to ensure valves are functioning correctly and to extend their operational life. A case study from a leading water management company highlights that regular maintenance checks reduced system downtime by 30% over a year. The authority and trust embedded in their maintenance protocols exemplify best practices for any industry utilizing these valves. Enhancing System Performance with the Right Check Valve To optimize system performance, understanding the dynamics of the system in which the 100mm check valve operates is essential. Considerations such as flow rate, pressure, and temperature all influence valve selection. Moreover, employing advanced simulation tools to model flow dynamics can provide valuable insights into how a valve will perform over its lifespan. Recommendations from specialists frequently highlight the importance of not just relying on manufacturer specifications but also considering the unique aspects of your system. This nuanced approach ensures the check valve will operate seamlessly within your system architecture. In conclusion, the 100mm check valve is not just a simple mechanical component but a vital element that contributes to the efficiency and safety of fluid systems. Leveraging expert knowledge and real-world experiences can guide the selection, installation, and maintenance processes, ensuring optimal performance and system reliability. This commitment to excellence is what ultimately fosters an environment of trust and authority in fluid system management.

Installation and Maintenance Insights Correct installation is pivotal for the effective operation of a 100mm check valve. Positioning and alignment must be precise, as even minor misalignments can lead to inefficient operation or failures. It is often recommended to have an experienced technician oversee the installation process. Periodic maintenance should also be prioritized to ensure valves are functioning correctly and to extend their operational life. A case study from a leading water management company highlights that regular maintenance checks reduced system downtime by 30% over a year. The authority and trust embedded in their maintenance protocols exemplify best practices for any industry utilizing these valves. Enhancing System Performance with the Right Check Valve To optimize system performance, understanding the dynamics of the system in which the 100mm check valve operates is essential. Considerations such as flow rate, pressure, and temperature all influence valve selection. Moreover, employing advanced simulation tools to model flow dynamics can provide valuable insights into how a valve will perform over its lifespan. Recommendations from specialists frequently highlight the importance of not just relying on manufacturer specifications but also considering the unique aspects of your system. This nuanced approach ensures the check valve will operate seamlessly within your system architecture. In conclusion, the 100mm check valve is not just a simple mechanical component but a vital element that contributes to the efficiency and safety of fluid systems. Leveraging expert knowledge and real-world experiences can guide the selection, installation, and maintenance processes, ensuring optimal performance and system reliability. This commitment to excellence is what ultimately fosters an environment of trust and authority in fluid system management.

Next:

Latest news

-

Types of Thread Gauge BSP Parallel DesignNewsAug.04,2025

-

Ring Gauge Cylindrical Check ApplicationNewsAug.04,2025

-

Machinist Gauge Pins GCr15 MaterialNewsAug.04,2025

-

Gate Valves for Sale Sewage System UseNewsAug.04,2025

-

Control Valve EPDM Seal MaterialNewsAug.04,2025

-

Cast Iron Y Type Strainer Flange Cover DesignNewsAug.04,2025

Related PRODUCTS