feb . 15, 2025 21:09 Back to list

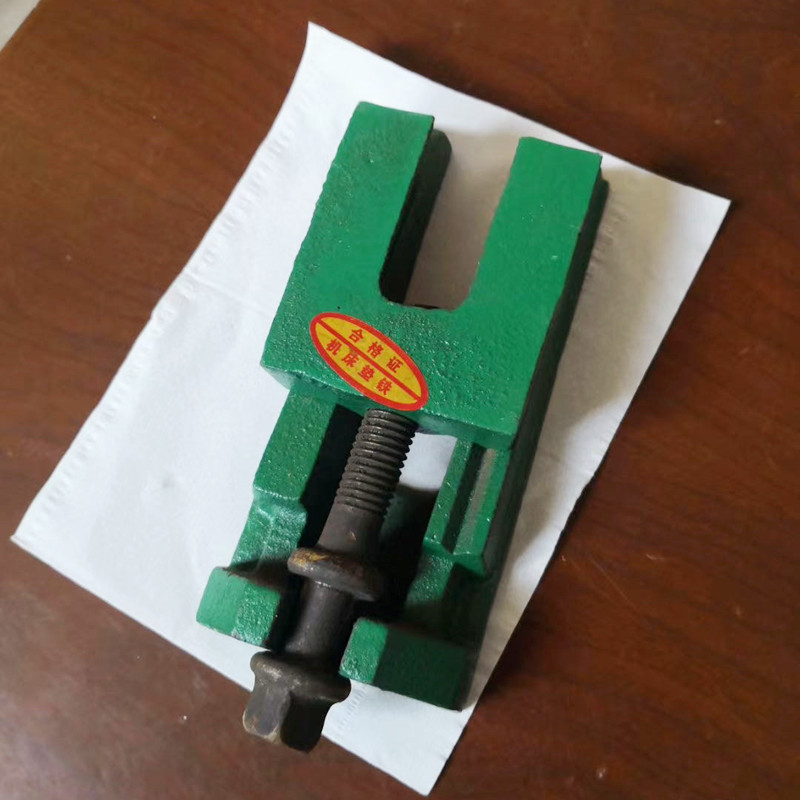

fixture table clamps

Fixture table clamps play a pivotal role in the realm of manufacturing and engineering, offering indispensable support to a variety of processes. Their major contribution lies in their ability to hold workpieces steady, ensuring precision during operations such as cutting, welding, and assembly. For those unfamiliar with these valuable tools, diving into the nuances of fixture table clamps can unearth a new appreciation for their function and necessity in manufacturing environments.

A significant consideration that elevates the expertise associated with fixture table clamps is their ease of use. Modern designs incorporate user-friendly mechanisms that allow for quick and secure fastening. This feature is particularly beneficial for operations requiring frequent adjustments or movements, as it minimizes downtime and allows workers to remain focused on their tasks. The ergonomic design of these clamps often incorporates intuitive locking systems that do not compromise safety, further enhancing trust in their daily use. The authoritativeness of fixture table clamps extends beyond individual workshops. They are a central theme in industrial safety standards and guidelines. Correctly using these tools not only ensures precision but also safeguards the workforce, reducing the risk of accidents caused by machinery. For engineers and safety managers, staying informed about the latest advancements and best practices in clamp design and usage is paramount. By participating in relevant workshops and training sessions, professionals can deepen their understanding and uphold safety standards within their establishments. Trustworthiness in the realm of fixture table clamps often starts with brand reputation. Companies known for producing reliable and innovative clamping solutions have spent years building and validating their credibility. Reviews and case studies from industry peers serve as testimonials, helping new users navigate their choices. Selecting clamps from a reputable manufacturer guarantees not only product quality but also access to technical support and customer service, ensuring that any unexpected issues can be swiftly resolved. To sum up, fixture table clamps are vital components that enhance precision, efficiency, and safety in manufacturing and industrial settings. Their diverse applications, combined with robust design and ease of use, position them as essential tools for anyone involved in detailed work requiring high levels of accuracy. As the industry continues to evolve, staying updated on the developments in fixture table clamp technology and maintaining rigorous standards can empower businesses to achieve exceptional performance levels while safeguarding their workforce. Understanding and leveraging the full potential of these clamps is not merely an operational imperative but a strategic advantage in a competitive marketplace.

A significant consideration that elevates the expertise associated with fixture table clamps is their ease of use. Modern designs incorporate user-friendly mechanisms that allow for quick and secure fastening. This feature is particularly beneficial for operations requiring frequent adjustments or movements, as it minimizes downtime and allows workers to remain focused on their tasks. The ergonomic design of these clamps often incorporates intuitive locking systems that do not compromise safety, further enhancing trust in their daily use. The authoritativeness of fixture table clamps extends beyond individual workshops. They are a central theme in industrial safety standards and guidelines. Correctly using these tools not only ensures precision but also safeguards the workforce, reducing the risk of accidents caused by machinery. For engineers and safety managers, staying informed about the latest advancements and best practices in clamp design and usage is paramount. By participating in relevant workshops and training sessions, professionals can deepen their understanding and uphold safety standards within their establishments. Trustworthiness in the realm of fixture table clamps often starts with brand reputation. Companies known for producing reliable and innovative clamping solutions have spent years building and validating their credibility. Reviews and case studies from industry peers serve as testimonials, helping new users navigate their choices. Selecting clamps from a reputable manufacturer guarantees not only product quality but also access to technical support and customer service, ensuring that any unexpected issues can be swiftly resolved. To sum up, fixture table clamps are vital components that enhance precision, efficiency, and safety in manufacturing and industrial settings. Their diverse applications, combined with robust design and ease of use, position them as essential tools for anyone involved in detailed work requiring high levels of accuracy. As the industry continues to evolve, staying updated on the developments in fixture table clamp technology and maintaining rigorous standards can empower businesses to achieve exceptional performance levels while safeguarding their workforce. Understanding and leveraging the full potential of these clamps is not merely an operational imperative but a strategic advantage in a competitive marketplace.

Next:

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS