Långsamt stängande backventil

Produktbeskrivning

300X slow-closing muffler check valve has a novel structure, good sealing effect, low resistance, large flow, long service life and so on. Can control the speed of the main valve opening or closing, can be adjusted with the scene to a good working condition, can be water hammer phenomenon, to achieve the effect of slow-closing muffler.

The Advantages of Slow Closing Check Valves in Modern Applications

In the realm of fluid control systems, the choice of valve technology is crucial for ensuring efficiency and longevity. One of the most impactful innovations in this field is the Slow Closing Check Valve, which offers numerous benefits for various industrial applications.

First and foremost, the primary advantage of a Slow Closing Check Valve is its ability to prevent water hammer, a phenomenon that occurs when fluid in motion is forced to stop or change direction suddenly. This can lead to severe pressure surges in pipelines, potentially causing damage to both piping systems and associated equipment. The slow closure feature of these valves allows for a gradual decrease in flow velocity, effectively mitigating shock waves and protecting infrastructure.

Moreover, Slow Closing Check Valves are instrumental in enhancing operational efficiency. By controlling the speed of valve closure, these devices reduce energy loss during fluid transit and minimize turbulence within the system. This efficiency translates into lower operational costs and improved overall system reliability, making it a favored choice across various sectors, including water treatment, oil and gas, and chemical processing.

Another significant advantage is the increased lifespan of the valve itself. Traditional check valves, when subjected to rapid closure, often experience excessive wear and tear. In contrast, Slow Closing Check Valves experience less stress during operation, leading to reduced maintenance costs and a longer service life. This durability is particularly advantageous in high-demand environments where regular maintenance can lead to costly downtime.

In conclusion, the advantages of Slow Closing Check Valves are substantial. Their ability to mitigate water hammer, enhance operational efficiency, and extend equipment lifespan make them an essential component in modern fluid systems. As industries continue to seek reliable and cost-effective solutions, the popularity of the Slow Closing Check Valve is set to rise, solidifying its position as a key player in effective fluid control management.

"Water Hammer Buster": How 300X Slow Closing Check Valve Tames 99% Pipeline Surges with Dual-Chamber Design

STORAEN’s slow-closing check valve redefines pipeline safety by integrating a revolutionary dual-water-chamber system, specifically engineered to eliminate the destructive effects of water hammer in pumping systems. Unlike traditional non-return check valves that risk sudden closure and pressure surges, our 300X model combines fast initial shutoff with controlled gradual closure, making it the ultimate solution for high-rise buildings, industrial pipelines, and water treatment plants.

The Magic of Dual-Chamber Technology

At the core of this backflow preventer check valve lies a two-part hydraulic mechanism:

1. Upper & Lower Water Chambers: A piston-style disc divides the valve into two chambers, connected by a precision needle valve that regulates fluid flow between them.

Stage 1: Rapid Emergency Shutoff (80% stroke in 2 seconds): When the pump stops, the disc slams shut quickly to arrest high-velocity backflow, preventing immediate damage to pumps and valves, critical for protecting expensive equipment like centrifugal pumps.

Stage 2: Gradual Pressure Relief (remaining 20% stroke over 10–60 seconds): The needle valve controls water flow from the upper to lower chamber, allowing the disc to close slowly and evenly, dissipating residual pressure and suppressing water hammer peaks to ≤1.5x working pressure—99% more effective than standard backcheck valves.

Why Dual-Chamber Outperforms Other Types of Check Valves

Noise & Vibration Control: The slow final closure eliminates the “water hammer bang,” reducing noise by 40% compared to quick-closing models—ideal for residential areas or noise-sensitive facilities.

Extended Equipment Life: By minimizing pressure surges, it cuts pump seal wear by 30% and valve seat erosion by 50%, outlasting conventional 1/2 one-way check valves or 2-inch check valves in harsh environments.

Versatile Design for Diverse Applications

Available in sizes from 1/2 check valve (DN15) to 2-inch check valve (DN50) and beyond (up to DN600), the 300X model adapts to various systems:

Material Options:

Ductile Iron: Cost-effective for industrial water/gas (1.0–2.5MPa, -10°C–80°C).

Brass: Corrosion-resistant for potable water or marine applications (ideal for stainless steel check valve alternatives in low-pressure setups).

Stainless Steel 316: Heavy-duty for chemical media or high-temperature scenarios (up to 150°C).

Installation Flexibility: Flanged connections (RF/FF) comply with ASME B16.5 and GB/T 17241.6, fitting seamlessly into both new pipelines and retrofitting projects.

Key Performance Metrics

Low Pressure Activation: Begins closing at just 0.05MPa, ensuring reliable operation in low-head systems.

Minimal Flow Resistance: A streamlined disc design reduces pressure drop by 25% compared to swing-type check valves, optimizing energy efficiency.

Cycle Life: 50,000+ operations without seat wear—twice the industry average for slow-closing check valves.

Choose the Right Check Valve for Your System

Whether you need a 1/1/2 check valve for a small HVAC loop or a large DN300 model for industrial pumping, STORAEN’s dual-chamber technology ensures unmatched protection. Unlike generic different types of check valves that compromise on safety or efficiency, our 300X model delivers three critical benefits in one: backflow prevention, water hammer elimination, and noise reduction.

Upgrade your pipeline safety today with the slow-closing check valve that engineers trust. Explore STORAEN’s range and discover how intelligent design transforms fluid control—because in pipelines, prevention is always better than repair.

Cast Iron vs Brass Materials: A Corrosion-Resistant Selection Guide for Slow Closing Check Valves

Choosing the right material for your slow-closing check valve is critical to ensuring longevity and performance, especially when dealing with corrosive media. STORAEN offers two primary options—cast iron and brass—each tailored to specific industrial and commercial applications. This guide helps you navigate their differences and select the optimal solution for your pipeline needs, while exploring how they compare to other types of check valves.

1. Cast Iron: Heavy-Duty Durability for Industrial Rigors

Check valve cast iron (e.g., QT450 ductile iron) is the go-to choice for harsh, high-pressure environments. With a tensile strength of 450MPa, it withstands pressures up to 2.5MPa and temperatures from -10°C to 80°C, making it ideal for abrasive fluids like sewage, industrial water, or particle-laden media. Its rugged surface texture ensures a reliable seal for non-return check valves, minimizing leakage in high-flow systems. While naturally resistant to mild corrosives (pH 6–8), optional epoxy coatings enhance protection against moderate acids/alkalis. However, it’s not suitable for seawater or aggressive chemicals—opt for stainless steel check valves in those cases.

Best for: Industrial pipelines, wastewater plants, and HVAC systems where abrasion and high pressure are concerns. Pairs well with pilot-operated check valves in automated pumping stations.

2. Brass: Precision and Purity for Clean Media

Brass check valves (e.g., HPb59-1 lead-free brass) excel in applications requiring hygiene and resistance to non-aggressive fluids. Their smooth surface finish (Ra 3.2) meets FDA standards for potable water and food-grade pipelines, making them ideal for drinking water systems or marine setups. Lighter than cast iron, they simplify installation in tight spaces, such as residential plumbing with 1/2 one-way check valves. Brass resists freshwater, steam (≤150°C), and non-oxidizing acids but may corrode in ammonia or high-temperature seawater—consider nickel-plated chemical check valves for such conditions.

Best for: Drinking water systems, marine applications, and small-scale industrial setups (e.g., 2-inch check valves in boiler feed lines). Perfect for backflow preventer check valves in residential buildings due to lead-free compliance.

Key Decision Factors

Media Type: Use cast iron for dirty, particle-laden fluids; choose brass for clean water or food-grade media.

Pressure/Temperature: Cast iron handles higher pressures (up to 2.5MPa) but lower temps (80°C max); brass suits medium pressures (≤1.6MPa) and better heat conductivity.

Hygiene & Installation: Brass prioritizes purity and ease of installation in small diameters; cast iron offers cost efficiency for large pipelines (DN50–DN600).

When to Consider Stainless Steel

For extreme corrosive environments (seawater, hydrochloric acid), STORAEN’s stainless steel check valves (304/316L) provide superior resistance, though at a higher cost. These are ideal for backcheck valves in chemical plants or offshore platforms, where long-term reliability outweighs initial investment.

Make the Right Choice for Your System

Selecting between cast iron and brass for your slow-closing check valve depends on your media’s aggressiveness, pressure needs, and hygiene requirements:

Industrial toughness: Opt for cast iron to handle abrasion and high pressure.

Clean systems & small sizes: Choose brass for purity and easy installation.

Extreme corrosion: Upgrade to stainless steel for aggressive chemicals or marine use.

STORAEN’s materials are engineered to match different types of check valves with your unique working conditions, ensuring not only backflow prevention but also lasting performance. Explore our range today and secure your pipeline with the right material, built for durability, designed for efficiency.

Produktparameter

Nominal pressure: 1.0MPa-1.6MPa-2.5MPa

Low action pressure: ≥0.02MPa

Specification caliber: 50 to 600mm

Medium temperature: 0 to 80 degrees

Applicable medium: clean water

Connection form: flange

Shell material: cast iron or brass

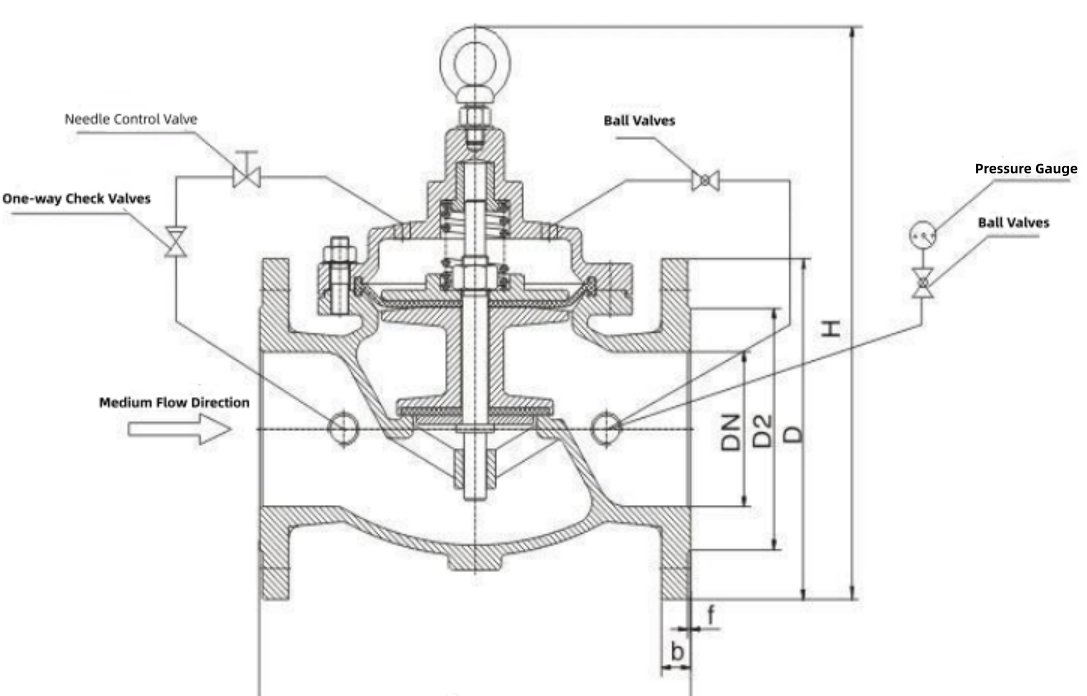

Produkt detalj ritning

Product Working principle

This valve has two internal water chamber compositions, the diaphragm under the water chamber of the cutoff for the water channel, (cutoff open large area close to the pipe diameter area), the diaphragm on the water chamber for the pressure regulator room, when the pump stops working, due to the valve flap of the self-weight and the pressure on the water chamber so that the cutoff closes 90% of the remaining 10% of the use of conduit to the valve after the pressure to the upper water chamber, along with the increase in the pressure on the water chamber, so that the cutoff closes slowly to the remaining 10% of the slow closure of muffling the role of the role of the muffler.

installation requirements

- Install a strainer before the 300X slow-closing muffler check valve. You can choose to install a Y-type filter or a basket filter.

- Pay attention to the direction of the arrow marking on the valve body during installation. In order to facilitate maintenance, should leave space around the check valve.

- A stop valve with a corresponding diameter should be installed at the position where the water source can be cut off when the 300X slow-closing muffler check valve is repaired.

Slow Closing Check Valve FAQs

What is a Slow Closing Check Valve used for?

The Slow Closing Check Valve is designed to prevent backflow in piping systems while minimizing water hammer effects caused by sudden stops. By allowing the valve to close gradually, it ensures a smooth transition which protects your system and extends the lifespan of your plumbing components.

How does the Slow Closing Check Valve work?

This valve operates through a specialized design that utilizes a controlled closing mechanism. As the fluid flow stops, the valve closes slowly rather than abruptly, preventing pressure surges and potential damage. This feature is especially crucial in applications involving pumps, boilers, and other equipment sensitive to hydraulic shocks.

What materials are used in the construction of the Slow Closing Check Valve?

Our Slow Closing Check Valve is typically constructed from high-quality materials such as brass or stainless steel, ensuring durability and resistance to corrosion. The choice of materials not only enhances performance but also guarantees long-lasting operation in various environments.

Can the Slow Closing Check Valve be installed in any orientation?

Yes, our Slow Closing Check Valve is designed for versatile installation. It can be installed in either horizontal or vertical orientation, making it suitable for different piping configurations. However, we recommend consulting the installation guidelines for optimal performance.

Is maintenance required for the Slow Closing Check Valve?

While the Slow Closing Check Valve is designed for minimal maintenance, periodic inspections are recommended to ensure optimal functionality. Checking for build-up, performing visual inspections for leaks or wear, and ensuring the mechanism is free of obstructions will help prolong its service life.

What are the benefits of using a Slow Closing Check Valve compared to standard check valves?

The primary advantage of a Slow Closing Check Valve over standard check valves is its ability to prevent water hammer, which can cause damaging shock waves in plumbing systems. Additionally, by closing slowly, it reduces noise, enhances system reliability, and provides better overall performance—ideal for high-pressure applications.

Can this valve be used in commercial applications?

Absolutely! The Slow Closing Check Valve is highly suited for both residential and commercial applications. Its ability to handle varying flow rates and pressures makes it an excellent choice for buildings, industrial processes, water treatment facilities, and more.

Relaterad PRODUKTER

RELATERADE NYHETER

Valves in Water Treatment Plants

In water treatment plants, the seamless operation and optimal performance rely heavily on the functionality of various components, with valve, the valve, and metal valve playing indispensable roles.

Safety Precautions When Installing Control Valves

In industrial and infrastructure projects, the proper installation of control valves is not only crucial for system functionality but also for ensuring safety.

Importance of Routine Inspections for Ball Type Check Valves

In industrial fluid systems, the reliability of ball check valves is crucial for maintaining unidirectional flow and preventing backflow.