May . 30, 2025 16:55 Khutlela lethathamong

Durability and Maintenance of Granite Fabrication Tables

In industrial manufacturing, granite fabrication tables are prized for their unmatched stability, vibration damping, and resistance to wear. Unlike granite inspection tables or granite reference plates, which prioritize ultra-precise measurement, fabrication tables are engineered to endure heavy machining, welding, and assembly tasks. For wholesalers, understanding how to preserve the integrity of these workhorses—while navigating bulk procurement challenges—is critical to meeting the demands of automotive, aerospace, and machinery clients. This article explores the durability of granite fabrication tables, compares their maintenance needs to other granite tools, and outlines strategies for wholesalers to deliver long-lasting value.

Granite Fabrication Tables: Engineered for Industrial Resilience

Granite fabrication tables are built to withstand the rigors of workshops, offering advantages that metal or wood tables cannot match. Granite’s natural properties—including low thermal expansion, non-conductivity, and hardness—make it resistant to warping, corrosion, and electromagnetic interference. Unlike granite inspection tables, which require near-perfect flatness, fabrication tables prioritize structural reinforcement.

For wholesalers, sourcing tables with sealed surfaces is key. High-quality epoxy or polymer seals prevent coolant, oil, or metal shavings from penetrating the granite’s micro-pores, which can degrade flatness over time. Bulk buyers, such as automotive Tier 1 suppliers, often demand tables pre-fitted with modular T-slot systems for clamping flexibility. Partnering with manufacturers offering customizable hole patterns or edge chamfering ensures wholesalers meet diverse client needs while maintaining durability.

Maintenance Demands: Fabrication Tables vs. Granite Inspection Tables

While granite fabrication tables and granite inspection tables share material benefits, their maintenance protocols differ significantly. Fabrication tables endure daily abuse—grinding sparks, heavy impacts, and chemical exposure—requiring proactive care:

Daily Cleaning: Use pH-neutral cleaners to remove oils and debris. Avoid acidic solutions that erode sealants.

Surface Inspections: Check for chips or scratches using straightedges. Minor flaws can often be repaired with granite filler, while major damage necessitates resurfacing.

In contrast, granite inspection tables operate in controlled environments, primarily requiring dust covers and periodic flatness verification. Wholesalers should educate bulk buyers on these differences, offering maintenance kits (cleaners, sealants, repair putty) as bundled accessories.

Granite Reference Plates: Insights for Enhancing Fabrication Table Longevity

Granite reference plates, used as calibration standards in metrology labs, exemplify granite’s longevity under optimal conditions. Though not designed for fabrication, their maintenance offers lessons:

Climate Control: Like reference plates, granite fabrication tables benefit from stable temperatures (20–22°C) to minimize thermal stress.

Handling Protocols: Use nylon slings—not metal hooks—to avoid edge damage during installation or transport.

Wholesalers can differentiate themselves by offering resurfacing services or leasing options for granite reference plates to clients testing fabrication table flatness.

Wholesale Granite Reference Plates Best Practices: Ensuring Durability in Transactions

Material Certification: Source granite from quarries with ISO 8512-3 compliance, verifying low porosity and homogeneity.

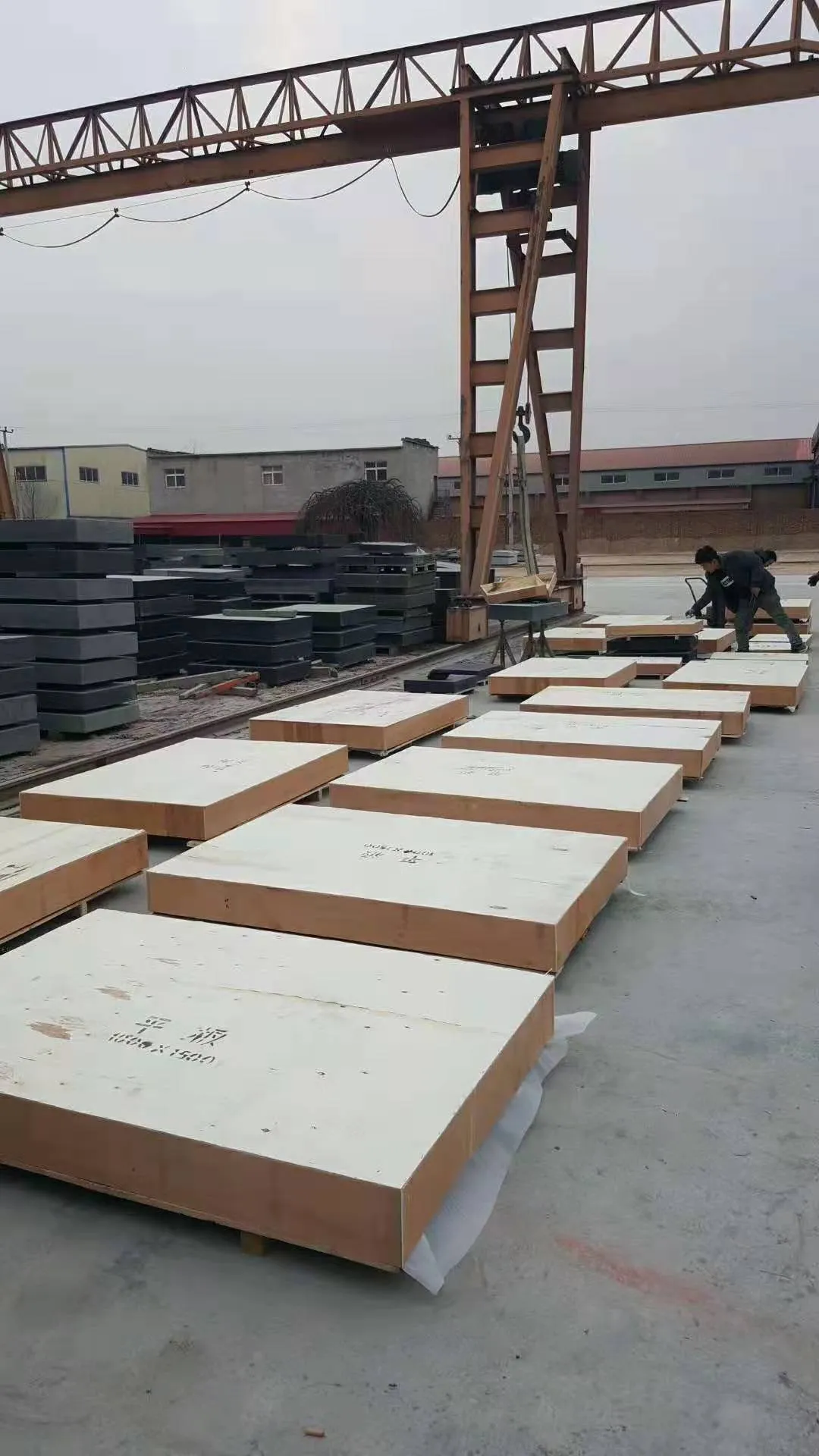

Robust Packaging: Use shock-absorbent crates with moisture barriers to prevent transit damage.

Supplier Audits: Inspect manufacturers’ quality control processes, focusing on sealing techniques and structural reinforcement.

Inventory Rotation: Sell older stock first to prevent prolonged warehouse exposure to humidity, which can weaken sealants.

By emphasizing these practices, wholesalers reduce returns and build trust with high-volume buyers like aerospace manufacturers.

FAQ: Granite Fabrication Table Durability and Maintenance

Can granite fabrication tables be repaired if chipped?

Yes. Epoxy-based granite fillers can repair minor chips. For deep damage, professional resurfacing restores flatness, though costs may vary based on severity.

How do fabrication tables compare to granite inspection tables in lifespan?

With proper maintenance, granite fabrication tables last 15–20 years, while granite inspection tables can exceed 30 years due to lighter usage.

Are sealed surfaces necessary for granite fabrication tables?

Critical. Sealants protect against stains and chemical penetration, preserving flatness. Unsealed tables degrade faster under industrial conditions.

What certifications should wholesalers prioritize when sourcing granite inspection tables?

Surface flatness, quality management, and granite calibration standards are essential for bulk buyers.

How can wholesalers reduce granite fabrication tables shipping damage for bulk orders?

Use reinforced wooden crates with foam lining, palletize shipments, and partner with freight carriers experienced in handling fragile industrial equipment.

For wholesalers, granite fabrication tables represent a lucrative niche, blending industrial durability with precision. By adopting maintenance insights from granite inspection tables and granite reference plates, distributors can offer clients tools that withstand decades of heavy use. Emphasizing material quality, certified suppliers, and proactive care positions wholesalers as partners in operational efficiency, securing long-term partnerships in the competitive manufacturing sector.

Moreover, wholesalers can differentiate themselves by offering granite fabrication tables with customizable features. This includes adjustable heights, integrated clamping systems, and customizable work surfaces to suit various fabrication needs. By listening to clients' specific requirements and working with skilled manufacturers, wholesalers can provide bespoke solutions that enhance productivity and reduce downtime. Additionally, offering training sessions or detailed manuals on how to maintain and optimize the use of granite fabrication tables can further solidify wholesalers' roles as trusted advisors in the industry.

-

Why the Right Angle Ruler Reigns in MetalworkingLitabaJul.21,2025

-

The Enduring Allure of Granite Boxes in Modern InteriorsLitabaJul.21,2025

-

The Digital Gauging Revolution: Reshaping Thread Rings Inspection's FutureLitabaJul.21,2025

-

How Modern Inspection Platforms Transcend Surface MeasurementLitabaJul.21,2025

-

How Customization Drives Wholesale Success in Parallel RulersLitabaJul.21,2025

-

Fortifying Permanent Steel Ground Anchors Against Corrosion's OnslaughtLitabaJul.21,2025

Tse amanang le PRODUCTS