сеп . 28, 2024 14:32 Back to list

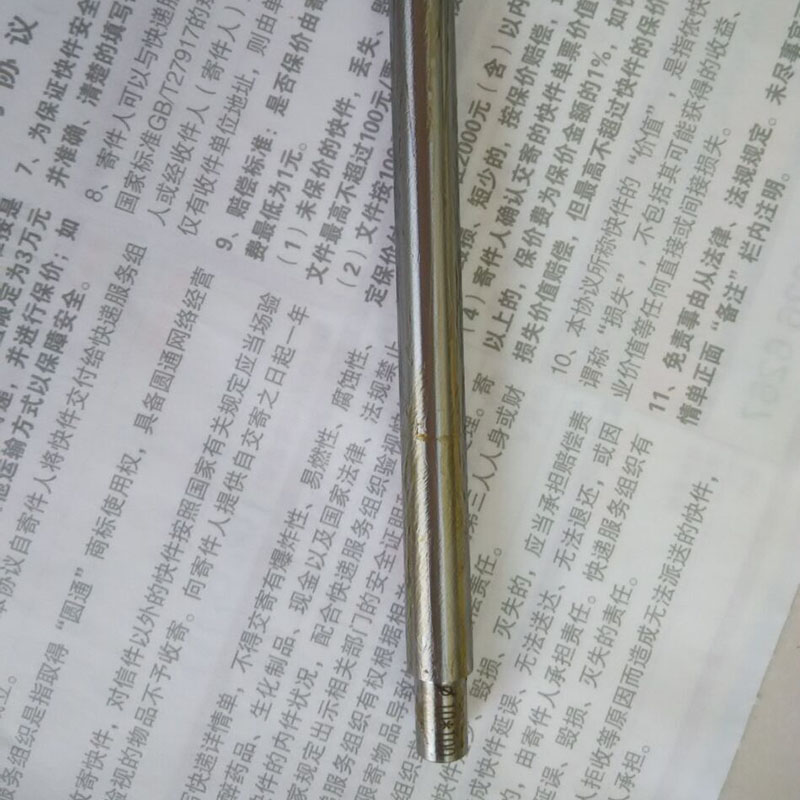

stainless steel check valve

The Importance of Stainless Steel Check Valves in Industrial Applications

Stainless steel check valves are essential components in various industrial applications, particularly in fluid and gas handling processes. These devices play a crucial role in preventing backflow, ensuring the efficient and safe operation of systems ranging from water treatment plants to chemical processing facilities. Understanding the unique attributes of stainless steel check valves and their applications can help in selecting the right valve for specific requirements.

What is a Check Valve?

A check valve, also known as a non-return valve, is designed to allow fluid to flow in only one direction. This is vital in applications where backflow could cause damage to equipment, contamination of the fluid, or operational inefficiencies. Check valves are engineered to automatically seal when fluid attempts to flow in the reverse direction, thus protecting the integrity of the system.

Why Stainless Steel?

Stainless steel is a preferred material in the manufacturing of check valves due to its outstanding properties. First and foremost, stainless steel offers excellent corrosion resistance, which is crucial in environments where chemicals, water, or other fluids can lead to rust and deterioration. This resistance extends the lifespan of the valve, reducing maintenance costs and downtime.

Moreover, stainless steel check valves can withstand high temperatures and pressures, making them suitable for a wide range of applications. Their structural integrity ensures that they perform reliably under demanding conditions, such as those found in oil and gas industries or food processing.

stainless steel check valve

Applications of Stainless Steel Check Valves

1. Water Treatment In water treatment facilities, stainless steel check valves prevent backflow of treated water, ensuring that the system operates efficiently and safely. They help maintain the quality of the water by avoiding cross-contamination.

2. Chemical Processing The chemical industry often uses highly corrosive substances, making stainless steel check valves an ideal choice. Their durability ensures that they can handle aggressive chemicals without degradation.

3. Food and Beverage In food processing, sanitary standards are paramount. Stainless steel check valves are easy to clean and maintain, making them perfect for ensuring hygiene while preventing contamination.

4. Oil and Gas These industries frequently demand equipment that can handle extreme conditions. The robust nature of stainless steel check valves allows them to perform reliably in high-pressure and high-temperature scenarios.

Conclusion

In conclusion, stainless steel check valves are indispensable in many industrial applications due to their durability, corrosion resistance, and reliability. Their ability to prevent backflow protects systems from potential damage, enhances operational efficiency, and ensures safety in various environments. When considering components for fluid and gas handling systems, choosing stainless steel check valves is a prudent decision that can lead to significant long-term benefits.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS