дец . 25, 2024 07:27 Back to list

Tips for Constructing Your Own Welding Table Efficiently and Effectively

Building a Welding Table The Essential Guide

Creating a dedicated welding table is a fundamental project for any welder. A good welding table not only provides a flat and stable surface for your projects but also enhances safety and efficiency in your work. In this article, we will guide you through the essential steps and considerations for making a welding table that meets your specific needs.

Step 1 Planning Your Welding Table

Before starting any construction work, it’s crucial to plan the design of your welding table. Consider the following factors

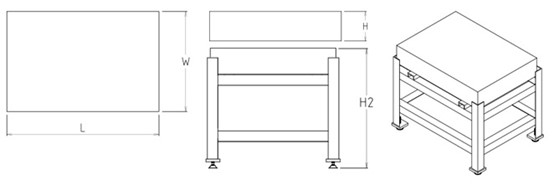

1. Size Determine the dimensions based on your typical projects. A standard size varies, but a good starting point is around 4 feet by 2 feet. If you often work on larger projects, you may need to increase the size.

2. Height The ideal height of a welding table should be comfortable for your working stance. Generally, it is around waist height. Some experienced welders prefer adjustable height tables for added versatility.

3. Material The tabletop material is critical. Common choices include steel and aluminum. Steel is more durable and can withstand higher temperatures, making it ideal for welding. Consider using a 1/4-inch or thicker steel plate for the top, as it prevents warping and provides a reliable surface.

4. Portability Decide whether you want a stationary table or a portable one on wheels. A mobile table can be advantageous for small workshops or when workspace is limited.

Step 2 Gather Materials and Tools

Once you have a design in mind, it’s time to gather your materials and tools. Here’s a basic list

- Steel or aluminum sheet for the tabletop - Steel tubing for the frame and legs - Angle grinder - Welding machine - Metal clamps - Measuring tape - Safety gear (gloves, mask, apron) - Level

Step 3 Constructing the Frame

Start by building the frame of your welding table. Cut your steel tubing to the desired lengths for the table legs and support beams. A common design features a rectangular frame, with four legs at each corner for stability.

1. Weld the Frame Position the cut tubing pieces and use clamps to hold them in place. Tack weld the corners before fully welding to ensure everything is square.

making a welding table

2. Add Cross Supports Strengthen the structure by adding cross supports beneath the tabletop. This will prevent sagging and increase the overall stability of the table.

3. Attach Legs Securely attach the legs to the corners of the frame. Ensure they are evenly spaced and square to provide a level working surface.

Step 4 Attaching the Tabletop

Once the frame is ready, it’s time to attach the tabletop

1. Place the Steel Plate Position the steel sheet on top of the frame. Ensure it overhangs evenly on all sides if that is part of your design.

2. Weld the Top Use even, consistent welds along the edges to secure the tabletop to the frame. Take care to prevent any warping by allowing the metal to cool as you work.

Step 5 Finishing Touches

After the welding is complete, you should consider a few finishing touches

1. Level the Table Use a level to check the surface. If needed, adjust the legs to ensure the table is perfectly flat.

2. Surface Treatment To prolong the life of your welding table, consider painting it with high-temperature paint or adding a rust-resistant coating.

3. Add Features Many welders enhance their tables with additional features like built-in clamps, storage for tools, or electrical outlets for equipment.

Conclusion

Making a welding table is a rewarding project that significantly boosts your welding capabilities. It not only provides a flat and sturdy surface but also helps keep your workspace organized and safe. By following these steps and carefully considering your needs, you can build a welding table that serves you well for years to come. Happy welding!

-

Welding Methods Used in Metal Table FabricationNewsJul.03,2025

-

Sustainable Materials in Silence Check Valve ManufacturingNewsJul.03,2025

-

Installation Guide for Cast Iron Y StrainersNewsJul.03,2025

-

How to Carve a Block of GraniteNewsJul.03,2025

-

Creating Customized Measurement PlatformsNewsJul.03,2025

-

Benefits of Using Granite Surface Plates in MachiningNewsJul.03,2025

Related PRODUCTS