нов . 26, 2024 09:23 Back to list

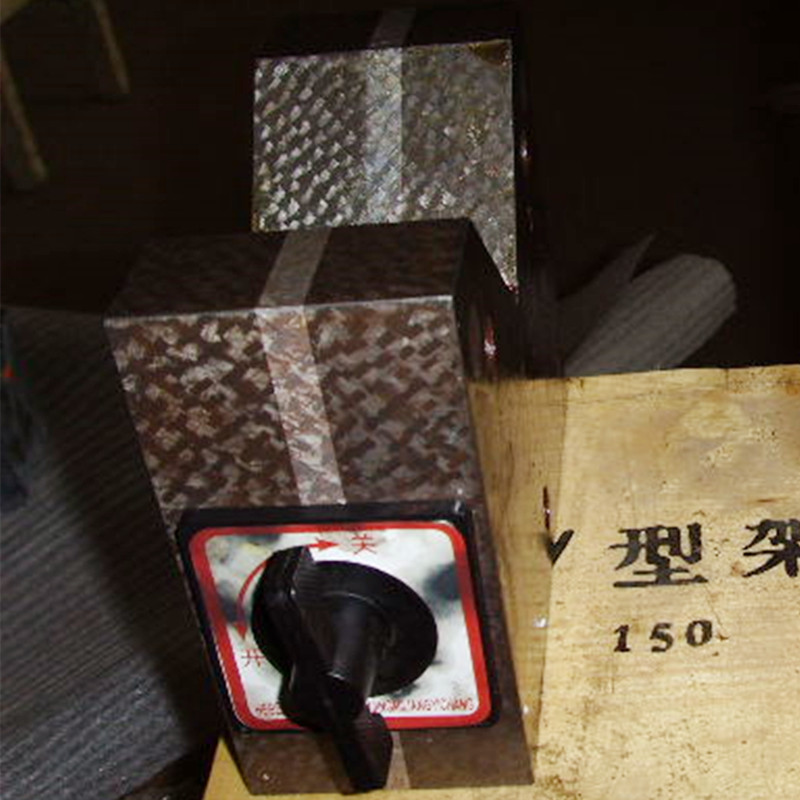

gate and globe valve

Understanding Gate and Globe Valves Essential Components in Fluid Control

Valves play a crucial role in various industries, including water supply, oil and gas, and manufacturing. Among the many types of valves available, gate valves and globe valves are two of the most commonly used. Each serves a distinct purpose and offers specific advantages and disadvantages, making them suitable for different applications. In this article, we will delve into the characteristics, functions, and uses of gate valves and globe valves.

Gate Valves The On/Off Control

Gate valves are primarily designed for on/off control of fluid flow. They operate by raising or lowering a gate or wedge-shaped disc into the flow path. This design allows for minimal flow resistance when the valve is fully open, translating to higher efficiency, especially in high-volume applications.

One of the primary advantages of gate valves is their ability to provide a straight-line flow path with very little pressure drop. This feature makes them ideal for applications where a fully opened or fully closed position is required, such as in water supply systems or oil pipelines. Additionally, gate valves are more suitable for situations where throttling or regulating flow is not needed, as they can cause turbulence and velocity changes if not fully opened.

However, gate valves do have some drawbacks. They are relatively slow to operate, requiring several turns to open or close fully. This can be an issue in emergency situations where quick responses are crucial. Furthermore, gate valves can suffer from wear and tear, especially in systems where the fluid contains particles that could erode the gate over time.

Globe Valves The Flow Control Champion

In contrast to gate valves, globe valves are designed for regulating and throttling flow. They utilize a spherical body and a movable disk that can be lowered onto a seat to block the flow partially or completely. This design allows for precise control over the flow rate and pressure, making globe valves ideal for applications requiring consistent and adjustable flow.

gate and globe valve

One of the significant advantages of globe valves is their effectiveness in throttling scenarios. They can control flow more accurately than gate valves, making them suitable for applications such as steam lines, heating systems, and many chemical processes requiring fine adjustments. Additionally, globe valves have a relatively simpler construction, which can lead to easier maintenance and repair.

However, globe valves also present some disadvantages. They generally have a higher pressure drop compared to gate valves due to the design that forces the fluid to change direction. This can lead to energy loss over time, making them less efficient in high-flow situations where minimal pressure drop is preferred. Moreover, the throttling motion can lead to increased wear and tear on the components, potentially shortening the valve's lifespan.

Choosing Between Gate and Globe Valves

The choice between gate and globe valves ultimately depends on the specific needs of the application. Gate valves are ideal for applications requiring a full-on or full-off functionality with minimal interference in flow. They are commonly used in water distribution, sewage systems, and oil pipelines.

On the other hand, globe valves shine in applications where precise flow regulation is crucial. Their ability to control the flow effectively makes them suitable for processes involving temperature or pressure variations, such as in chemical plants and power generation facilities.

In selecting the appropriate valve, engineers and designers must assess various factors, including the type of fluid, system pressure, temperature, and required flow rates. Understanding the characteristics of gate and globe valves will aid in making informed decisions, ultimately leading to enhanced system efficiency and reliability.

Conclusion

Gate and globe valves serve vital functions in fluid control systems across numerous industries. While gate valves excel in on/off operations with minimal pressure drop, globe valves provide excellent flow regulation and control. By understanding the strengths and weaknesses of each type, professionals can make informed choices that cater to their specific operational needs, ensuring the efficiency and longevity of their systems.

-

Thread Plug Gauge Our Promise of Measurement ExcellenceNewsAug.22,2025

-

Gauge Pin Class Reflecting Quality LegacyNewsAug.22,2025

-

Check Valve Types for High Rise BuildingsNewsAug.22,2025

-

Water Control Valve for Irrigation SystemsNewsAug.22,2025

-

Gate Valve with Soft Seal TechnologyNewsAug.22,2025

-

Y Type Strainer for Oil and Gas ApplicationsNewsAug.22,2025

Related PRODUCTS