Niveli i imazhit të përbërë optik

përshkrim i produktit

- 1.Aplikimi

Niveli i imazhit të përbërë optik përdoret gjerësisht në matjen e gradientëve të sipërfaqes së sheshtë dhe sipërfaqes cilindrike në drejtim horizontal; Rrafshin dhe drejtësinë e rrëshqitjes ose bazës së veglës së makinës ose instrumentit mekanik optik, si dhe korrektësinë e pozicionit të instalimit të pajisjes.

- 2.Të dhënat teknike

(1) çdo vlerë diplomimi: ...0.01mm/m

(2) diapazoni maksimal i matjes: ...0~10mm/m

(3) lejimi: ...1mm/brenda një metri... 0.01mm/m

Brenda diapazonit të plotë të matjes...0.02mm/m

(4) devijimi i planit në sipërfaqen e punës...0.0003mm/m

(5) çdo vlerë gradimi të nivelit të alkoolit...0.1mm/m

(6) sipërfaqja e punës (LW): ...165 48mm

(7) pesha neto e instrumentit: ...2 kg.

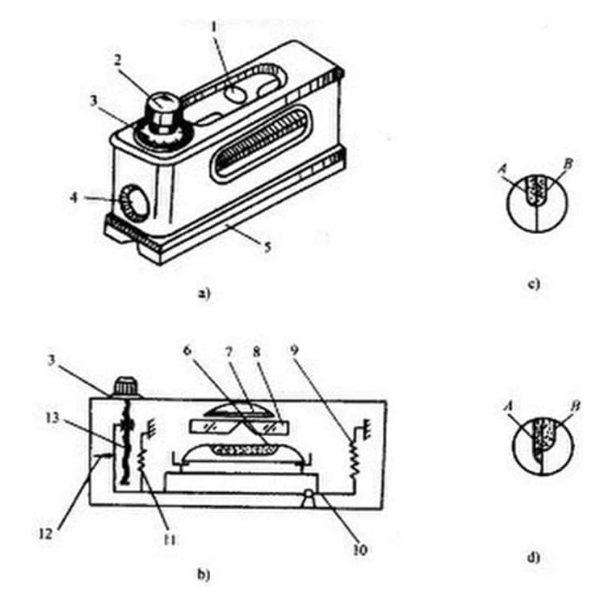

- 3. Struktura e instrumentit:

Niveli i imazhit kompozit përbëhet kryesisht nga pjesët e mëposhtme si vidhos rregulluese mikro, dado, disku i shkallëzuar, niveli i spirmës, prizmi, xham zmadhues, leva si dhe baza me sipërfaqe pune të thjeshtë dhe v.

- 4. Parimi i punës:

Niveli i imazhit të përbërë përdor prizmin për të marrë imazhet e flluskave të ajrit në përbërjen e nivelit të frymës dhe të zmadhuara për të rritur saktësinë e leximit dhe përdor sistemin e transmetimit të levës dhe mikrovidave për të rritur ndjeshmërinë e leximit. Prandaj, nëse pjesa e punës me një gradient prej 0.01 mm/m, mund të lexohet me saktësi në nivelin e imazhit të përbërë (niveli i frymës në nivelin e imazhit të përbërë kryesisht luan rolin e treguesit zero).

- 5. Metoda e funksionimit:

Vendosni nivelin e imazhit të përbërë në sipërfaqen e punës të pjesës së punës matëse dhe gradienti i pjesës matëse të punës shkakton mospërputhje të imazheve të flluskës së ajrit tërheqës; Rrotulloni diskun e graduar derisa imazhet e flluskës së ajrit të tërheqjes të përkojnë dhe leximi mund të merret menjëherë. Gradienti aktual i pjesës së punës matëse mund të llogaritet me formulën e mëposhtme:

Gradient aktual=vlerë gradient Distanca bazë Leximi i diskut

Shembull dhelpra: Leximi i diskut: 5 gradient; Meqenëse ky nivel i përbërë i imazhit është i lidhur me vlerën e gradientit dhe distancën e pikëmbështetjes, kjo është vlera e gradientit: 0,01 mm/m dhe distanca e pikës kryesore: 165 mm.

Pra: Gradient aktual=165mm 5 0.01/1000=0.00825mm

- 6.Njoftimi për operimin:

(1) para përdorimit, pastroni pluhurin e vajit me benzinë dhe më pas pastroni me garzë absorbuese.

(2) Ndryshimi i temperaturës ka ndikim të madh në instrument dhe për këtë arsye ai duhet të ndahet me burim nxehtësie për të shmangur gabimin.

(3) Gjatë matjes, rrotullojeni diskun e graduar derisa imazhet e flluskës së ajrit tërheqës të përkojnë plotësisht dhe më pas mund të merren leximet si në drejtimet pozitive ashtu edhe në ato negative.

(4) If the instrument is found with in correct zero position, it may be adjusted; Put the instrument on a stable table and rotate the graduated disc to set the tow air bubble images coincide to get first reading a; Then turn the instrument by 180o and put back to its original place. Ra-rotate the graduated disc to get the tow air bubbles coincide to get the second reading b. So 1/2 (α +β ) is the zero deviation of the instrument. Loosen the three supporting screws on the graduated disc and press lightly by hand the embossed adjusting cap; Rotate the disc by 1/2 (α +β) to get the zero deviation and the point line composite; At last fasten the screws.

(5) Pas punës, sipërfaqja e punës e instrumentit duhet të pastrohet dhe të lyhet me vaj pa acid, anhydrous, antindryshk dhe letër kundër ndryshkut; Vendoseni në kuti druri dhe më pas ruajeni në një vend të pastër të thatë.

Hot Tags: Optical Composite Image Level Optical Composite Image Level suppliers China Optical Composite Image Level Optical Composite Image Level factory stable Optical Composite Image Level

Parametri i produktit

Parametrat teknikë

- Dial i vlerës së pllakës 0,01 mm/m

- Gama e matjes 0-10 milimetra/metër

- Parent-child error within ± 1mm/m+0.01 mm/m

- The parental error within the entire measurement range is ± 0. 02 millimeters/meter

- Devijimi i rrafshimit të stolit prej 0.003 mm

- Standardi i akumulimit të vlerës së qelizës 0.1 milimetra/metër

- Madhësia e tavolinës së zyrës 165 x 48 milimetra

- Pesha neto 2.2 kilogramë

Optical Composite Image Level Maintenance: Antirust Oil & Storage Tips

Proper maintenance ensures your optical composite image level retains its 0.01mm/m precision and durability. Follow these steps to protect its prism technology and mechanical components:

1. Daily Cleaning for Surface Protection

After use, wipe working surfaces (V-groove, edges, lenses) with isopropyl alcohol on a lint-free cloth to remove oils and dust. Use a soft brush for stubborn debris—never abrasives, which can scratch optical parts or damage metal coatings. This preserves the precision ground surfaces (Ra ≤ 0.1μm) critical for accurate readings.

2. Routine Antirust Care for Metal Parts

While the granite base resists corrosion, metal components (screws, levers, hinges) need protection. Apply Storaen’s non-acidic anti-rust oil every 3 months or after moisture exposure:

Apply thinly to threads and pivots with a dropper, avoiding pooling on granite/lenses.

Prevents seizing: Maintains lever mechanism sensitivity (0.001mm precision) for cylindrical slope measurements.

3. Optimal Storage Practices

Store in the included hard case or a dry cabinet to avoid temperature/humidity damage:

Environment: 10°C–30°C, <60% humidity to prevent lens condensation and optical distortion.

Positioning: Lay flat or upright in padded slots; never under heavy objects to avoid misaligning the optical system.

Long-term storage: Reapply anti-rust oil and add a silica packet; inspect 24 hours before use, verifying zero position via 180° rotation calibration.

4. Monthly Functional Inspections

Check performance regularly to ensure reliability:

Bubble clarity: Confirm the composite bubble image aligns smoothly without blur.

Lever movement: Test micro-screws for smooth rotation—stiffness signals needed lubrication.

Flatness check: Use a reference plate to validate factory-calibrated flatness (±0.0003mm/m).

5. Storaen’s Support for Longevity

Leverage our expert services to maintain peak performance:

Factory recalibration: Restores 0.01mm/m precision via ISO-certified equipment for critical applications.

Genuine parts: Replacement components ensure compatibility and preserve original accuracy.

By following these steps, your Storaen optical composite image level will deliver consistent precision for industrial alignment tasks, backed by our 30+ years of engineering expertise.

Zero Position Calibration of Optical Composite Image Level: 180° Rotation Method Explained

Accurate zero calibration is vital for your Storaen optical composite image level to maintain its 0.01mm/m precision and ±0.0003mm/m flatness. The 180° rotation method eliminates subtle optical or mechanical shifts, ensuring reliable measurements in critical tasks like CNC machine alignment or aerospace component inspection. Here’s a streamlined, step-by-step guide:

1. Why Calibrate?

Impacts, vibrations, or temperature fluctuations can shift the level’s zero reference, leading to measurement drift. Calibration realigns the bubble vial with the tool’s optical prism and lever system, ensuring consistent baselines for industrial applications where 0.001mm deviations are unacceptable—such as verifying machine tool guides or structural frameworks.

2. Setup Requirements

Storaen optical composite image level (featuring a V-grooved base and micro-adjusting screw)

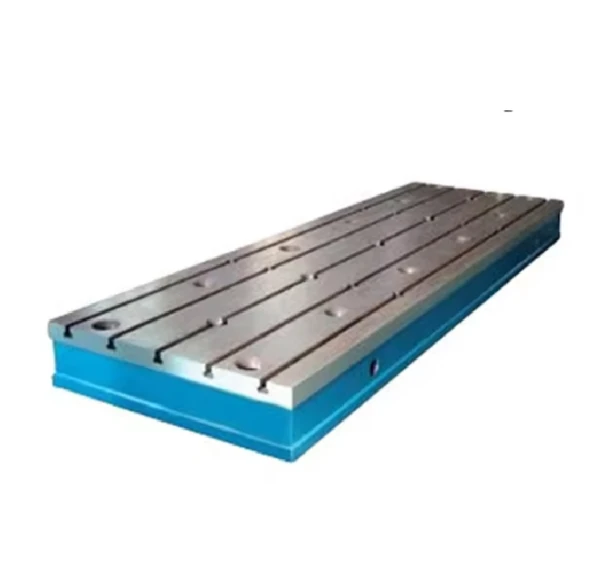

Certified precision reference flat (e.g., our Storaen granite surface plate, with flatness ≤0.0002mm/m)

A clean, vibration-free workbench in a temperature-stabilized environment (18°C–22°C recommended)

3. Step 1: Initial Measurement

Place the level lengthwise on the reference flat, aligning the V-grooved base with the flat’s central axis. Rotate the micro-adjusting screw until the composite bubble image—created by the 45° prism system—perfectly overlaps in the viewfinder. Record this initial scale reading (A), which reflects the current deviation from true zero.

4. Step 2: 180° Rotation & Second Reading

Carefully flip the level 180° end-to-end while maintaining its longitudinal orientation on the flat (avoid any lateral movement). Adjust the micro-screw again to align the bubble image and record the new reading (B). The difference Δ = |A - B| indicates zero position error; ideal values for Storaen levels should be ≤0.005mm/m.

5. Step 3: Error Correction & Verification

Calculate the target zero position as the midpoint: C = (A + B)/2. Loosen the protective cap on the zero-adjustment screw (typically located near the bubble vial), rotate the screw until the scale reads C, then retighten. Repeat Steps 3–4 until Δ ≤0.002mm/m, ensuring minimal residual error.

6. Pro Tips for Precision

Triple-Check Consistency: Perform 3 calibration cycles, especially after transporting the level or working in environments with temperature swings, to ensure repeatable results.

Lubricate Moving Parts: Apply a drop of Storaen’s non-acidic oil to the micro-screw before adjustment to ensure smooth, backlash-free operation and prevent binding.

Environmental Control: Avoid calibrating near heat sources or drafts, as even minor temperature gradients can affect the granite base’s dimensional stability and introduce errors.

7. Storaen’s Calibration Support

Every Storaen optical composite image level includes a NIST-traceable calibration certificate, but quarterly in-field checks are recommended for heavy use. Our support includes:

Factory Recalibration: Restoring original 0.01mm/m accuracy using laser interferometers for high-stakes applications.

Genuine Spare Parts: Readily available adjustment screws and maintenance kits for long-term usability.

Video Tutorials & Expert Guidance: Step-by-step videos and engineer support to assist with on-site calibration procedures.

Final Notes

Mastering the 180° rotation method ensures your Storaen optical composite image level delivers the precision required for cylindrical slope measurements, machine tool flatness checks, and other critical alignments. With proper calibration, this tool, backed by our 30+ years of engineering expertise, becomes an indispensable asset in your quality control workflow, ensuring every measurement is as reliable as the first.

Të lidhura PRODUKTET

LAJME TË LIDHUR

Durable Cast Iron Y Strainer Solutions for Industrial Buyers

For industrial fluid systems requiring reliable filtration, Storaen (Cangzhou) International Trading Co. offers premium Cast Iron Y Strainer solutions alongside our comprehensive Flanged Strainer product line.

Cast Iron Lapping Plates for Precision Engineering Solutions

When superior flatness and durability matter most, Cast Iron Lapping Plates from Storaen (Cangzhou) International Trading Co. deliver unmatched performance.

Thread Plug Gauge Requires Careful Handling

In the world of manufacturing and engineering, precision is non-negotiable—especially when it comes to threads, which are critical components in machinery, construction, and everyday products.