Qer . 26, 2025 14:29 Kthehu në listë

Pin Gauge Training Programs for Enhanced Dimensional Inspection Skills

Dimensional inspection is a cornerstone of quality control in manufacturing, ensuring components meet precise specifications. Among the tools critical to this process, pin gauges stand out for their accuracy and reliability. To maximize their effectiveness, specialized training programs are essential. These programs equip inspectors with the skills to leverage pin gauges, calibrated pin gauges, pin gauge sets, and standard pin gauges effectively. This article explores how structured training enhances inspection outcomes, emphasizing the role of these tools in industrial applications.

Understanding the Role of Pin Gauge in Precision Measurement

A pin gauge is a cylindrical tool designed to verify the dimensional accuracy of holes, slots, and other features. Its simplicity belies its importance: even minor deviations in hole diameters can lead to assembly failures or performance issues. Training programs begin by familiarizing inspectors with the fundamentals of pin gauge usage, including selection, handling, and interpretation of results.

Key topics in this phase include:

- Material Compatibility:Understanding how pin gauges interact with different workpiece materials to avoid wear or damage.

- Tolerance Alignment: Matching pin gaugesto specified tolerances to ensure measurements align with design requirements.

- Environmental Factors: Addressing temperature, humidity, and cleanliness to maintain measurement integrity.

By mastering these basics, inspectors lay the groundwork for advanced applications involving calibrated pin gauges and multi-tool systems like pin gauge sets.

Optimizing Accuracy with Calibrated Pin Gauges

Calibrated pin gauges are precision instruments traceable to national or international standards, ensuring their measurements are consistently accurate. Training programs emphasize the importance of calibration cycles, certification protocols, and error mitigation strategies.

A well-structured curriculum covers:

- Calibration Intervals: Establishing schedules to maintain the accuracy of calibrated pin gaugesover time.

- Certification Documentation: Interpreting calibration certificates to verify tool compliance.

- Error Identification: Recognizing signs of wear or misalignment in calibrated pin gaugesbefore they compromise results.

Hands-on exercises simulate real-world scenarios, such as measuring high-tolerance aerospace components or automotive parts. Trainees learn to cross-reference calibrated pin gauges with digital measurement systems, reinforcing the importance of redundancy in critical inspections.

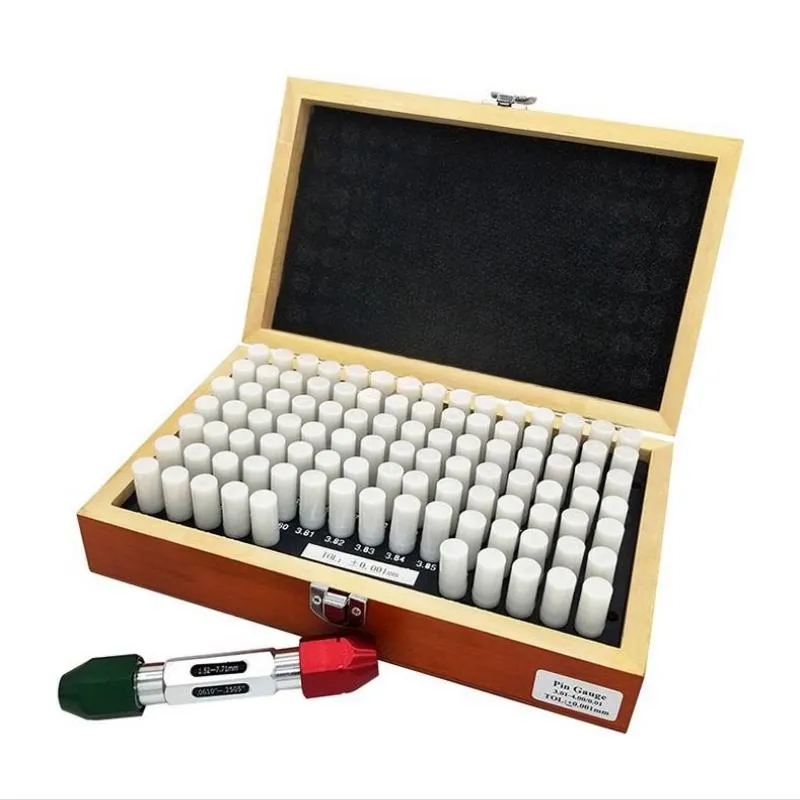

Mastering Versatility with a Pin Gauge Set

A pin gauge set combines multiple gauges of varying diameters, enabling inspectors to tackle diverse measurement tasks efficiently. Training programs focus on optimizing the use of these sets through systematic approaches.

Critical training modules include:

- Set Organization: Categorizing gauges by size, tolerance, or application to streamline workflows.

- Rapid Selection Techniques: Using gauge blocks or digital catalogs to identify the right pin gaugefrom a set quickly.

- Cross-Validation:Employing multiple gauges from a pin gauge set to validate measurements and reduce uncertainty.

For example, in medical device manufacturing, a pin gauge set might be used to inspect injection-molded parts with tight tolerances. Trainees practice sequencing measurements from largest to smallest pin diameters, ensuring seamless transitions between gauges.

smallest pin diameters, ensuring seamless transitions between gauges.

Ensuring Compliance with Standard Pin Gauge Practices

Standard pin gauges serve as reference tools for establishing baseline measurements across production lines. Training programs highlight their role in maintaining consistency, especially in industries like automotive or electronics where batch uniformity is critical.

Key training objectives include:

- Reference Alignment:Using standard pin gauges to calibrate other measurement tools or fixtures.

- Batch Testing: Implementing standard pin gaugesto validate entire production runs against design specs.

- Audit Preparedness: Preparing documentation trails that demonstrate compliance using standard pin gauges.

Case studies often illustrate how deviations detected by standard pin gauges have prevented costly recalls. For instance, a deviation in fuel injector holes identified during routine checks can trigger process adjustments before defective parts reach assembly.

FAQs About Pin Gauge Training Programs

What industries benefit most from training on pin gauge usage?

Industries such as aerospace, automotive, medical devices, and electronics rely heavily on pin gauges for high-precision inspections. Training ensures personnel can meet industry-specific standards like AS9100 or ISO 13485.

How often should calibrated pin gauges be rechecked for accuracy?

Calibrated pin gauges should undergo recalibration annually or per manufacturer guidelines. Heavy-use environments may require shorter intervals to maintain traceability.

Can a pin gauge set replace digital measurement tools?

A pin gauge set complements digital tools by providing physical verification. While digital systems offer speed, pin gauges deliver unambiguous pass/fail results for go/no-go inspections.

Why are standard pin gauges critical for quality audits?

Standard pin gauges provide auditable proof of measurement consistency. Their traceable certifications help organizations demonstrate compliance during regulatory reviews.

What safety protocols apply when handling pin gauges?

Inspectors should wear gloves to prevent contamination, store pin gauges in protective cases, and avoid dropping them to preserve calibration integrity.

Investing in pin gauge training programs elevates dimensional inspection capabilities, reducing errors and enhancing product quality. By mastering pin gauges, calibrated pin gauges, pin gauge sets, and standard pin gauges, inspectors become adept at navigating complex manufacturing environments. As industries continue to demand higher precision, these skills will remain indispensable for maintaining competitive edge and operational excellence.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlLajmeAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseLajmeAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsLajmeAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesLajmeAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingLajmeAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlLajmeAug.05,2025

PRODUKTET NË LIDHJE