Dhj . 04, 2024 16:18 Back to list

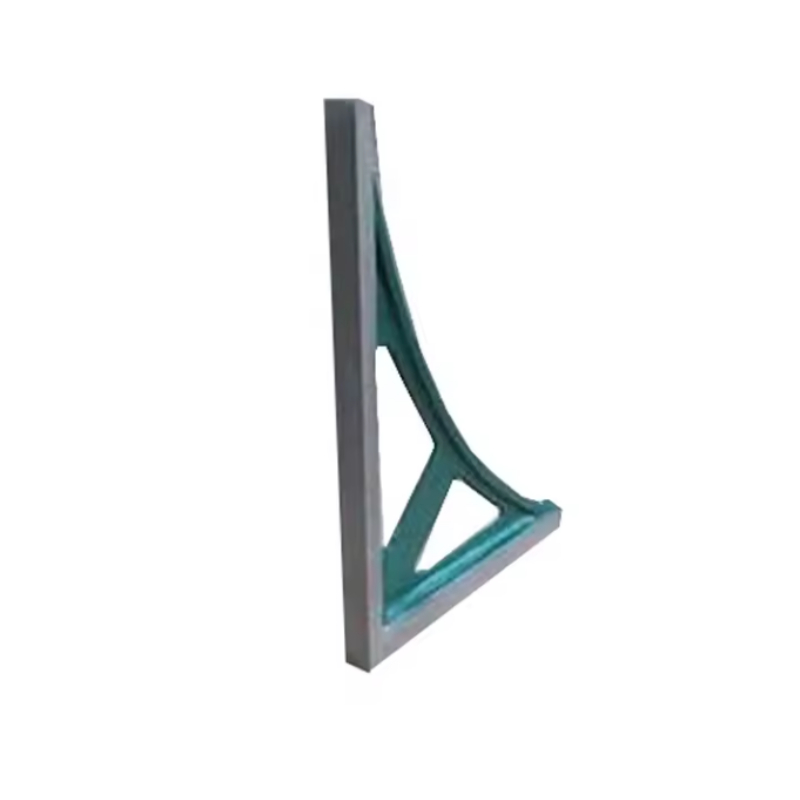

one way water valve

Understanding One-Way Water Valves Essential Components for Fluid Control

In the world of fluid dynamics, one crucial component that plays a significant role is the one-way water valve, also known as a check valve. These devices ensure that water or any fluid flows in one direction only. Their design prevents backflow and maintains the appropriate pressure levels in various systems. Understanding the functionality and applications of one-way water valves is essential for industries reliant on fluid transport and management.

The Design and Functionality of One-Way Water Valves

A one-way water valve is designed to allow fluid to pass through in only one direction while preventing reverse flow. Typically, these valves consist of a movable disc or ball that opens under pressure and seats back to create a seal when pressure decreases. The simplicity of their design is what makes them so effective. By utilizing this mechanism, these valves can protect pumps, pipelines, and other components from potential damage caused by backflow.

One-way water valves vary in design. Some common types include swing check valves, diaphragm check valves, and ball check valves. Each type is suited for specific applications, offering advantages based on their construction and the required flow rate.

Applications of One-Way Water Valves

One-way water valves are integral to numerous applications across various industries. In plumbing systems, they prevent sewage from flowing back into clean water lines, ensuring the integrity of drinking water supplies. In irrigation systems, these valves maintain pressure, enhancing the efficiency of water distribution. Additionally, in industrial settings, check valves are used in pipelines to protect equipment from backflow, which could lead to contamination or damage.

one way water valve

Moreover, one-way water valves are commonplace in automotive systems. They help regulate the flow of fuel and air in engines, contributing to optimal performance and fuel efficiency. In medical applications, these valves can be found in intravenous systems, allowing fluids to flow to patients without the risk of backflow, thus ensuring safety and efficacy.

Importance of Proper Installation and Maintenance

While one-way water valves are relatively low maintenance, improper installation or neglect can lead to significant issues. Ensuring that these valves are installed in the correct orientation is crucial, as incorrect placement can lead to failure in their function. Regular inspections can help identify wear and tear, allowing for proactive replacements before larger problems develop.

Future Innovations in One-Way Water Valves

As technology continues to advance, the design and efficiency of one-way water valves are also evolving. Innovations such as smart valves, which can monitor flow rates and conditions in real-time, are on the rise. These contemporary designs are equipped with sensors that provide feedback, enabling better management of water resources and enhancing system performance.

Conclusion

One-way water valves are indispensable components in fluid management systems, providing safety and efficiency across various applications. Understanding their design, functionality, and importance allows industries to leverage these devices effectively. As technology advances, the future of one-way water valves promises even greater efficiency and innovation, helping to meet the growing demands of fluid management in an ever-evolving landscape. Recognizing the significance of these small yet powerful devices can lead to improved operations and sustainability in numerous fields, from plumbing and irrigation to automotive and healthcare.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS