Sht . 14, 2024 08:42 Back to list

level manufacturer

Understanding Level Manufacturers and Their Importance in Industry

In today's rapidly evolving industrial landscape, the term level manufacturer has gained significant attention. This designation refers to companies that produce goods or components that are used in various levels of manufacturing processes. Understanding the significance of level manufacturers is vital for businesses looking to optimize their operations and enhance their supply chains.

Level manufacturers are integral across multiple sectors, from automotive and aerospace to consumer goods and electronics. They serve as critical suppliers, providing essential parts that contribute to the functionality and efficiency of final products. For instance, in the automotive industry, level manufacturers produce components such as engine parts, transmission systems, and electronic controls. These components are not only vital for the assembly process but also impact the overall performance and safety of vehicles.

Moreover, level manufacturers are often positioned differently in the supply chain compared to original equipment manufacturers (OEMs). While OEMs focus on the final assembly and branding of products, level manufacturers deal primarily with the production of specific components. This distinction allows them to specialize in particular processes, enabling greater innovation and efficiency. By concentrating on a limited range of products, level manufacturers can invest in advanced production technologies, achieving higher precision and quality in their output.

level manufacturer

The importance of level manufacturers goes beyond mere production; they play a crucial role in the strategic planning of manufacturing businesses. Companies must carefully select their level manufacturers based on various factors like quality, cost, reliability, and delivery times. A well-chosen level manufacturer can significantly reduce production costs and lead times, enhancing a company’s competitiveness in the marketplace. With global supply chains becoming increasingly complex, the ability to collaborate closely with level manufacturers is essential for maintaining operational efficiency.

Additionally, the rise of automation and digitization in manufacturing has further stressed the importance of level manufacturers. With Industry 4.0 technologies transforming traditional manufacturing paradigms, level manufacturers are increasingly required to adapt and innovate. This shift often involves investing in smart manufacturing techniques, such as the Internet of Things (IoT) and artificial intelligence (AI), which can streamline production processes and enhance product quality.

Furthermore, sustainability has become a pressing concern for the manufacturing industry. Level manufacturers are now tasked with adopting sustainable practices and producing eco-friendly products. This can involve using renewable materials, reducing waste, and implementing energy-efficient processes. Companies are increasingly favoring level manufacturers who prioritize sustainability, recognizing that responsible manufacturing practices can lead to enhanced brand loyalty and marketability.

In conclusion, level manufacturers are an essential component of the manufacturing ecosystem. Their role as specialized suppliers helps ensure that businesses can deliver high-quality products efficiently and sustainably. As industries continue to evolve, the collaboration between companies and level manufacturers will become increasingly critical, driving innovation and excellence in manufacturing processes. Emphasizing strong partnerships with level manufacturers will undoubtedly pave the way for future success in a competitive market.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

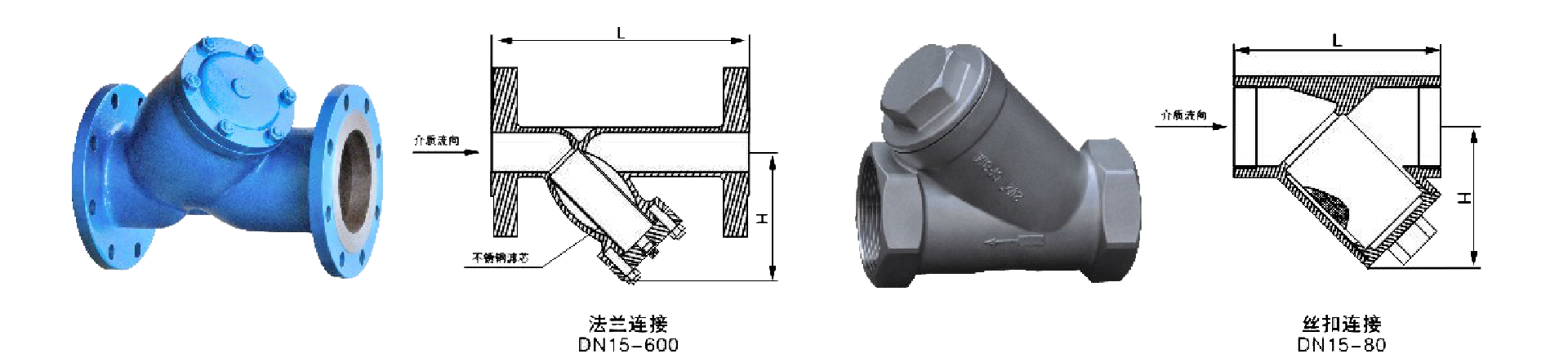

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS