Jul . 04, 2025 09:47 Toe fo'i i le lisi

Thread Micrometer Set Features

Precision measurement in manufacturing requires specialized tools like micrometer set products, particularly when dealing with threaded components. The indicating micrometer and thread micrometer set offer distinct advantages for different measurement scenarios. This guide explores the key characteristics of these essential precision instruments.

Precision Features of Micrometer Set

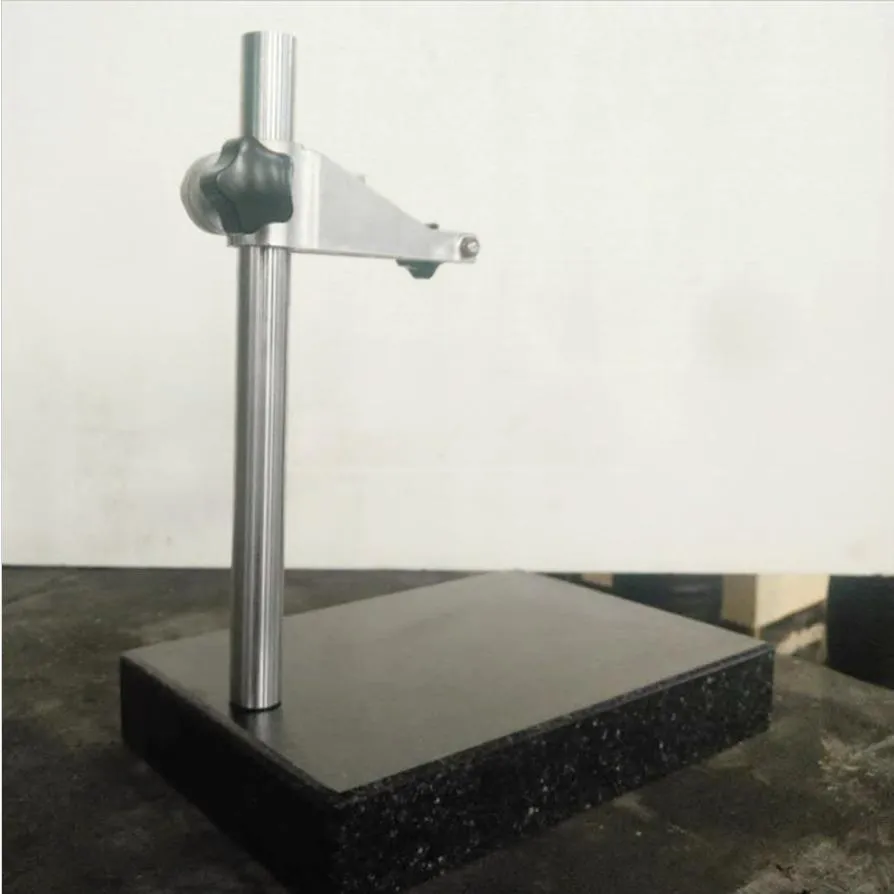

- Granite construction provides exceptional stability for micrometer set bases

• Non-magnetic properties make indicating micrometer tools ideal for sensitive environments

• Acid/alkali resistant materials ensure long-term thread micrometer set durability

• Wear-resistant surfaces maintain micrometer set accuracy through extended use

• Thermal stability prevents deformation in indicating micrometer components

|

Igoa Oloa |

Fua maualuga maamora fua fa'avae fua fa'avae micrometer spial Fua vili |

||||||||

|

Mea |

Granite |

||||||||

|

Lanu |

natura |

||||||||

|

Sa'o |

00 vasega |

||||||||

|

OEM |

ioe |

||||||||

|

Malosi |

2970-3070kg/Kupita mita |

||||||||

|

malosi fa'amalosi |

245-254N/m |

||||||||

|

malosi fa'amalosi |

itiiti ifo i le 0.13% |

||||||||

|

Coefficient o le faalauteleina laina |

4.61*10-6/tikeri |

||||||||

|

Fa'atatauga |

Vaega su'esu'e |

||||||||

|

Fua Fa'atatau |

Sa'o |

Vasega |

Umi Fa'avae |

Fa'avae lautele |

Maualuga Maualuga |

maualuga pa |

Umi lima |

||

|

100*150mm |

0.002 |

00 |

150 |

100 |

50 |

250 |

140 |

||

|

150*150mm |

0.002 |

00 |

150 |

150 |

50 |

250 |

140 |

||

|

200*150mm |

0.002 |

00 |

200 |

150 |

50 |

300 |

140 |

||

|

300*200mm |

0.002 |

00 |

300 |

200 |

50 |

300 |

180 |

||

|

400*300mm |

0.002 |

00 |

300 |

300 |

50 |

300 |

180 |

||

|

600*400mm |

0.002 |

00 |

400 |

300 |

50 |

300 |

180 |

||

Technical Specifications of Thread Micrometer Set

- Measuring ranges tailored for various micrometer setapplications

• Resolution down to 0.001mm in premium indicating micrometermodels

• Parallelism accuracy within 0.002mm for thread micrometer set anvils

• Hardened measuring faces on micrometer set for extended service life

• Ratchet stop mechanisms ensure consistent indicating micrometer pressure

Industrial Applications for Indicating Micrometer

- Quality control inspection using thread micrometer setsa'o

• Machining process verification with micrometer setaccuracy

• Thread pitch measurement via specialized indicating micrometer tools

• Workshop calibration standards employing thread micrometer set references

• Research and development applications requiring micrometer set reliability

Measurement Advantages of Thread Micrometer Set

- Direct thread measurement without calculations using micrometer settools

• Consistent results across multiple indicating micrometeroperators

• Rapid measurement capability with thread micrometer set efficiency

• Comprehensive data collection using digital micrometer set models

• Traceable accuracy standards for certified indicating micrometer instruments

Maintenance Guidelines for Micrometer Set

- Regular cleaning of thread micrometer setmeasuring surfaces

• Proper storage in protective cases for micrometer setlongevity

• Periodic calibration verification for indicating micrometer accuracy

• Careful handling to prevent thread micrometer set damage

• Environmental controls to maintain micrometer set performance

Micrometer Set FAQS

Q: How does a micrometer set differ from an indicating micrometer in measurement tasks?

A: A micrometer set typically includes multiple types of micrometers (e.g., outside, inside) for various dimensional checks. In contrast, an indicating micrometer uses a dial or digital display to show minute measurement changes, often focusing on precision depth or thickness readings. Sets offer versatility, while indicating micrometers prioritize high-accuracy, real-time measurements.

Q: When should I choose a thread micrometer set over a standard micrometer set?

A: Select a thread micrometer set when measuring thread pitch diameters, crucial in machining, automotive, or plumbing. Its specialized anvils and spindles fit precisely into threads, ensuring accurate readings. A standard micrometer set, on the other hand, suits general-purpose linear measurements like length, width, or diameter of non-threaded components.

Q: What maintenance is required for an indicating micrometer within a micrometer set?

A: For an indicating micrometer in a set, regularly clean the measuring surfaces with a lint-free cloth to remove debris. Check the calibration annually using a gauge block, as its sensitive dial or digital mechanism can drift over time. Avoid dropping the tool, as impact may misalign the indicator, compromising accuracy across the entire micrometer set.

Q: Can a thread micrometer set measure different thread types?

A: Yes, many thread micrometer sets come with interchangeable measuring heads to accommodate various thread profiles (e.g., metric, imperial, Acme). However, ensure the set matches your specific thread type’s pitch and angle requirements. If unsure, consult the manufacturer’s guide or opt for a universal set that covers common industrial threads.

Q: How do I ensure accuracy when using a micrometer set that includes an indicating micrometer and thread micrometer set?

A: Before use, calibrate each micrometer against a known standard. When measuring, apply consistent measuring force—too much can distort readings, too little may yield inaccurate results. For thread micrometers, align the anvils precisely with the thread flanks. For indicating micrometers, zero the dial or display at the start. Regularly check and maintain all components within the micrometer set to uphold long-term accuracy.

Welcome to Storaen Machinery – Where Precision Forges the Future,Nestled in Botou, China’s ancient casting capital, Storaen (Cangzhou) International Trading Co. blends 2,000 years of metallurgical heritage with cutting-edge engineering. We’re not just manufacturers—we’re architects of industrial reliability, crafting cast iron welding platforms, precision measuring tools, and gauges that define accuracy for global industries.

Our portfolio is a testament to innovation: from granite inspection blocks with HS70+ hardness to digital micrometer sets that measure down to 1μm. Every product carries the Botou legacy—cast in premium alloys, ground to 00-grade flatness, and tested through 27 quality checks. But our edge isn’t just in metal—it’s in mindset. We turn client challenges into custom solutions, whether a aerospace-grade parallel ruler or a factory-scale welding platform.

Sustainability runs through our forges: recycled materials, energy-efficient casting, and a carbon-neutral supply chain. Join partners in 46 countries who trust us to power their precision. Explore www.strmachinery.com to discover how 21st-century tech meets timeless craftsmanship. Let’s shape the future—one micron at a time.

-

Flanged Gate Valve: A Reliable Choice for Industrial and Municipal SystemsTala FouAug.20,2025

-

Soft Seal Gate Valve: A Modern Solution for Reliable Pipeline ControlTala FouAug.20,2025

-

Gate Valve Types: Understanding the Options for Your Pipeline SystemsTala FouAug.20,2025

-

Y Type Strainer: Essential for Clean and Efficient Flow SystemsTala FouAug.20,2025

-

Cast Iron Y Strainer: Durable Solutions for Demanding ApplicationsTala FouAug.20,2025

-

Flanged Y Strainer: An Essential Component in Industrial Filtration SystemsTala FouAug.20,2025

O'OGA Fa'atatau