Dec . 29, 2024 03:32 Back to list

Precision Welding Techniques and Standards for Optimal Performance and Quality

Precision Welding A Comprehensive Guide with Reference to Welding Tables

Precision welding is an essential process in many industries, characterized by its ability to create strong, durable, and high-quality joints between materials. This technique is crucial in manufacturing, automotive, aerospace, and construction, where the integrity and performance of structures depend heavily on the quality of welds. One valuable tool in achieving precision in welding is the use of welding tables.

Understanding Precision Welding

Precision welding involves controlled welding parameters to ensure minimal distortion, excellent fusion, and precise formation of welds. It requires a thorough understanding of various welding methods, such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and laser welding, each providing unique benefits for specific applications.

A skilled welder must consider factors such as material type, thickness, electrode specifications, and the environment in which the welding occurs. For instance, aluminum and stainless steel require different approaches due to their thermal properties and reaction to heat. Utilizing a welding table can significantly enhance the precision and consistency of these processes.

The Importance of Welding Tables

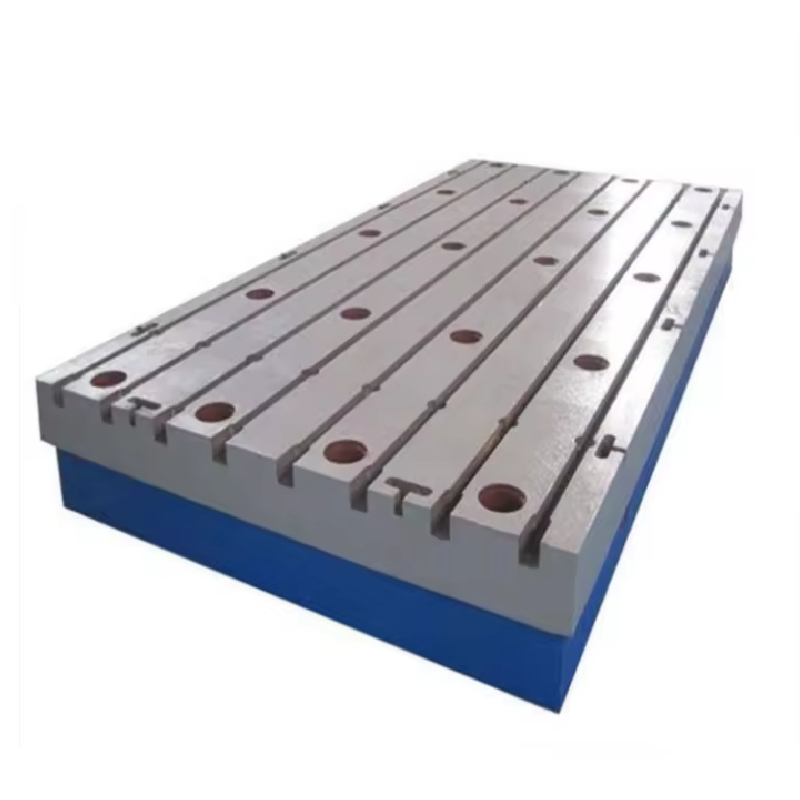

Welding tables provide a flat, stable surface on which to work, allowing welders to secure workpieces efficiently. Here are some key benefits of using welding tables for precision welding

1. Stability A solid welding table minimizes vibration and movement during the welding process, leading to more accurate results.

2. Versatility Many welding tables come equipped with adjustable fixtures and clamps that can accommodate various shapes and sizes of materials, making them suitable for multiple projects.

3. Accuracy The flat surface helps in aligning workpieces perfectly, contributing to precise joints and consistent weld quality.

precision welding table

5. Safety A dedicated welding table ensures that the welder has a safe, organized workspace, reducing the risk of accidents that could occur due to clutter or instability.

Selecting the Right Welding Table

Choosing the right welding table involves considering several factors that align with the specific requirements of the tasks at hand. Here are some essential criteria to keep in mind

- Size and Weight Capacity Ensure the table can support the weight and size of the materials being welded, with a surface area large enough to accommodate your projects comfortably.

- Material Welding tables can be made from various materials, including steel, aluminum, or composite materials. The choice of material can affect the table's durability and suitability for specific welding environments.

- Modularity Some welding tables allow for the addition of accessories and attachments. Modular tables provide flexibility for future projects and enable users to adapt their setup as needed.

- Surface Treatment A treated surface can enhance durability and prevent wear and tear, which is particularly important in high-use environments.

- Portability If the welding job requires moving from one location to another, consider a table that's lightweight and easy to transport.

Conclusion

Precision welding plays a critical role in manufacturing and construction, ensuring that the integrity of the final product meets stringent standards. The integration of welding tables into the welding process dramatically enhances the quality, accuracy, and efficiency of welds. By investing time in selecting a suitable welding table and employing precision welding techniques, professionals can significantly improve their output and achieve the highest level of craftsmanship. Ultimately, whether in a high-tech manufacturing facility or a small workshop, a reliable welding table is an indispensable asset for any skilled welder aiming for perfection.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS