Dec . 05, 2024 09:05 Back to list

High-Precision Bore Gauge for Accurate Measurement and Quality Control in Manufacturing

Precision Bore Gauge An Essential Tool for Quality Control in Manufacturing

In the world of manufacturing and engineering, precision is paramount. Components must meet exact specifications to ensure proper functionality, safety, and performance. One of the key tools in achieving this level of precision is the bore gauge, particularly the precision bore gauge. This specialized instrument plays a vital role in measuring the internal diameters of cylindrical objects with high accuracy, making it indispensable in various industries such as automotive, aerospace, and machining.

What is a Precision Bore Gauge?

A precision bore gauge is an instrument used to measure the diameter of a bore or hole with great accuracy. Typically designed with a set of interchangeable anvils and a calibrated measuring head, it allows users to assess the dimensions of internal features of components. The gauge can measure different sizes by changing the anvil to fit the specific bore size, making it versatile and adaptable for multiple applications.

How Does It Work?

The basic operation of a precision bore gauge involves inserting the gauge into the bore to be measured. Once inside, the gauge is expanded until it makes contact with the walls of the bore. The user then locks the gauge in place and extracts it from the bore. The measurement is taken from a micrometer or a digital readout that indicates the internal diameter based on the gauge’s calibrated scale.

To ensure utmost accuracy, precision bore gauges typically feature a robust design, often incorporating hardened steel or specialized alloys that withstand wear and tear over time. Many modern gauges come equipped with digital displays, greatly enhancing readability and reducing the potential for human error in data interpretation.

Applications of Precision Bore Gauges

Precision bore gauges are widely used in various sectors. In the automotive industry, they are essential for inspecting the internal dimensions of engine blocks, piston cylinders, camshafts, and other critical components. These measurements ensure parts fit together correctly, promoting optimal fluid dynamics and engine performance.

precision bore gauge

In the aerospace sector, where safety and performance are crucial, precision bore gauges help in scrutinizing components like landing gear housings and fuel nozzle assemblies. Any deviation from specified dimensions can have catastrophic consequences, hence the need for rigorous quality control processes.

In machining environments, these gauges assist in managing tolerances for pipe fittings, gearboxes, and machinery housings. Manufacturers utilize precision bore gauges to ensure parts are manufactured to exact specifications, minimizing discrepancies during assembly.

Advantages of Using Precision Bore Gauges

Using a precision bore gauge offers several distinct advantages. First and foremost is accuracy. These gauges can measure to extremely fine tolerances, often down to microns, ensuring that parts meet stringent quality standards. This precision helps reduce waste and rework costs associated with manufacturing non-compliant components.

Additionally, the use of precision bore gauges enhances efficiency. They enable quick and reliable measurements, promoting faster inspection times compared to traditional measuring techniques. This efficiency translates to shorter production cycles and improved throughput in manufacturing settings.

Moreover, precision bore gauges contribute to improved quality control. By incorporating these tools into the production and inspection process, manufacturers can guarantee that their components meet all necessary specifications, thereby maintaining high standards and reputation in their respective industries.

Conclusion

The precision bore gauge stands as a testament to the importance of accuracy in modern manufacturing. Its ability to deliver reliable measurements of internal diameters makes it an invaluable tool for quality control in diverse applications. Whether in the hands of a machinist, engineer, or quality inspector, precision bore gauges enable businesses to uphold their commitment to excellence, ensuring that every component produced meets the highest standards of performance and reliability. As industries continue to evolve and require even stricter tolerances, the relevance of precision bore gauges will only grow, leading the way towards enhanced manufacturing processes and innovations.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

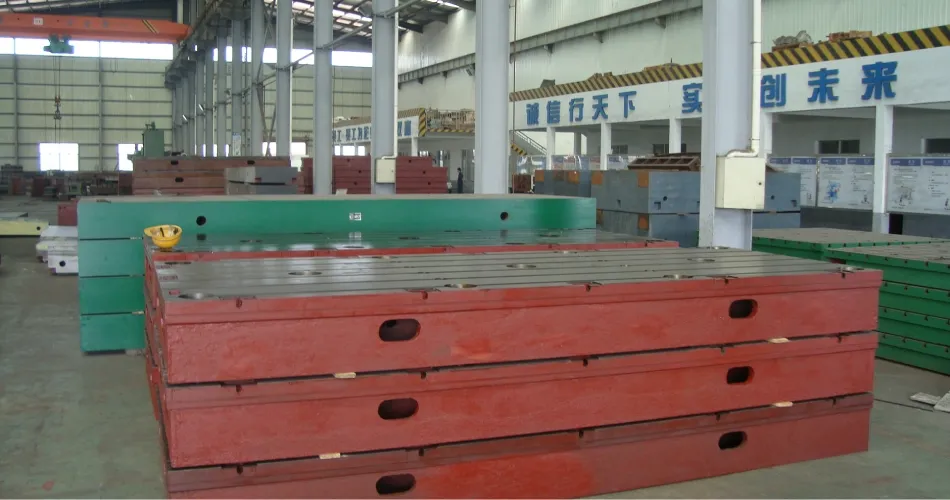

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS