Oct . 22, 2024 13:29 Back to list

No-Go Pin Gauge for Precision Measurement and Quality Control in Manufacturing

Understanding No-Go Pin Gauges Precision in Measurement

In the realm of manufacturing and engineering, precision is critical. One essential tool that plays a significant role in ensuring that parts meet specific dimensions is the no-go pin gauge. This article delves into what no-go pin gauges are, their applications, and the significance of precision in measurement.

What is a No-Go Pin Gauge?

A no-go pin gauge is a specific type of measurement tool used to check whether a hole or other internal feature meets predetermined specifications. It is part of a larger family of pin gauges that also includes go gauges. While a go gauge is used to verify that a feature is within the acceptable limits, the no-go gauge serves to ensure that a feature is not larger than its maximum allowable dimension.

The no-go pin gauge is characterized by its slightly larger diameter compared to the corresponding go gauge. When using a no-go gauge, if the gauge fits into the hole or feature being measured, it indicates that the dimension is out of tolerance, meaning the part fails inspection. Conversely, if the no-go gauge does not fit, the part is considered acceptable.

Applications of No-Go Pin Gauges

No-go pin gauges have a wide range of applications across various industries, including automotive, aerospace, and manufacturing. They are particularly useful in scenarios where consistent precision is paramount, such as in the following applications

1. Quality Control In manufacturing, quality control departments use no-go gauges as part of their inspection processes. By employing these gauges, they can quickly ascertain whether production parts conform to design specifications, thus preventing faulty parts from moving through the production line.

2. Assembly Processes No-go gauges ensure that components fit together correctly during assembly. For instance, if a hole is too large for a no-go pin gauge, it may cause issues during assembly, leading to weakened structures or improper functioning.

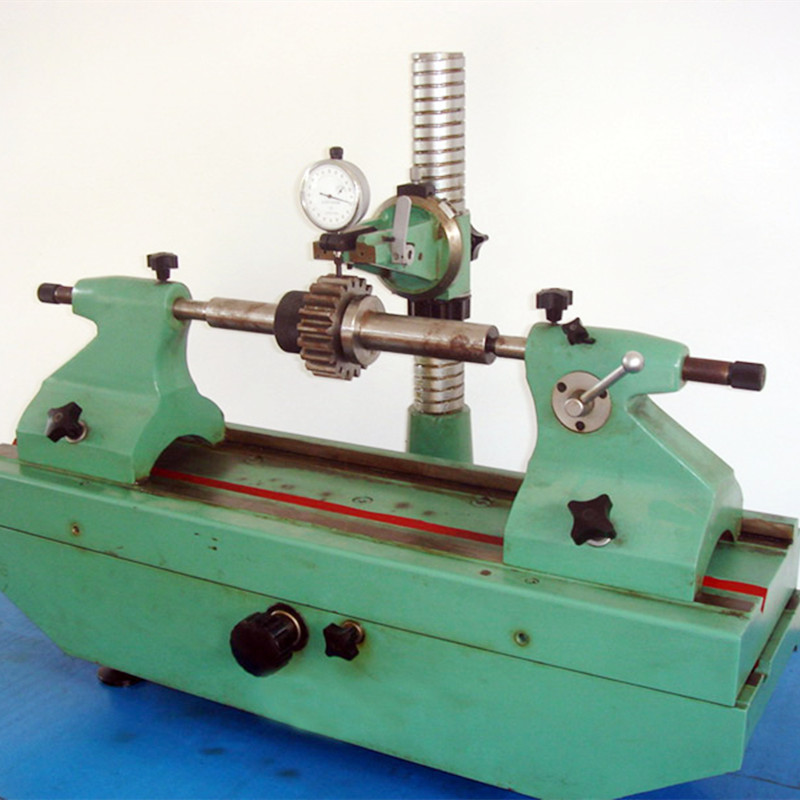

no go pin gauge

3. Maintenance and Repair In sectors like aerospace and automotive, maintenance crews utilize no-go gauges to check tolerance levels of various components. This ensures that parts are not only within acceptable tolerances but also safe for operation.

4. Toolmaking In tool and die making, creating precise components is essential. No-go gauges are used to verify that dies and molds remain within tolerance over time, ensuring that they produce consistent parts.

The Importance of Precision

Precision in measurement is vital for several reasons. First, it helps maintain the safety and functionality of the final products. A slight deviation from the specified dimensions can lead to severe consequences, especially in critical components like those found in airplanes or medical devices.

Secondly, precision enhances efficiency. When parts fit correctly, there is less likelihood of rework or scrap, which can be costly and time-consuming. By employing no-go gauges, manufacturers can reduce the risk of producing out-of-tolerance parts, saving resources and improving productivity.

Lastly, precision measurement tools like no-go pin gauges help build customer trust and satisfaction. Products manufactured to precise specifications are more likely to meet customer expectations, which is essential for maintaining a competitive edge in today’s market.

Conclusion

In summary, no-go pin gauges are integral tools in modern manufacturing and engineering. They play a crucial role in quality control, assembly, maintenance, and tool-making processes by ensuring that components meet predetermined specifications. The importance of precision cannot be overstated, as it directly impacts safety, efficiency, and customer satisfaction. By understanding and effectively utilizing no-go pin gauges, industries can foster a culture of quality and precision, leading to better products and enhanced operational success.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS