Feb . 10, 2025 11:01 Back to list

6 inch butterfly valve price

Understanding the pricing landscape of the 6-inch butterfly valve requires more than just a superficial overview. As a seasoned industry expert, the insights provided here come from in-depth experience and analysis within the industrial valve sector, taking into account factors that influence cost and highlighting the essential elements needed for making informed purchasing decisions.

Moving from factors influencing price to the benefits of strategic investment in robust valves, the total cost of ownership (TCO) emerges as another critical consideration. Initial purchase price is just one part of the equation; maintenance, energy efficiency, and operational downtime significantly influence the TCO. High-quality valves minimize leakage, reduce repair frequency, and improve operational efficiency, converting to financial savings over time. Furthermore, sustainability concerns are increasingly influencing buyer decisions. Recognizing that energy efficiency and eco-friendly manufacturing processes are gaining priority, manufacturers develop valves designed to reduce environmental impact, often with higher price tags justified by these values. Navigating the diverse market landscape to determine appropriate pricing requires a strategic approach, balancing upfront costs with potential long-term benefits. Engaging directly with reputable suppliers and manufacturers can provide bespoke solutions aligning with your specific needs and budget constraints, ensuring you receive the best value for your investment. In an ever-evolving industrial space, staying well-informed about emerging trends and advancements in valve technology can provide a competitive edge. Awareness of regulatory updates, new materials, and innovation in smart valve technologies will aid in anticipating market shifts and making strategic purchases aligned with future operational needs. Ultimately, understanding the intricate dynamics behind the pricing of a 6-inch butterfly valve allows decision-makers to prioritize elements that contribute to operational effectiveness, ensuring both fiscal responsibility and product performance are achieved.

Moving from factors influencing price to the benefits of strategic investment in robust valves, the total cost of ownership (TCO) emerges as another critical consideration. Initial purchase price is just one part of the equation; maintenance, energy efficiency, and operational downtime significantly influence the TCO. High-quality valves minimize leakage, reduce repair frequency, and improve operational efficiency, converting to financial savings over time. Furthermore, sustainability concerns are increasingly influencing buyer decisions. Recognizing that energy efficiency and eco-friendly manufacturing processes are gaining priority, manufacturers develop valves designed to reduce environmental impact, often with higher price tags justified by these values. Navigating the diverse market landscape to determine appropriate pricing requires a strategic approach, balancing upfront costs with potential long-term benefits. Engaging directly with reputable suppliers and manufacturers can provide bespoke solutions aligning with your specific needs and budget constraints, ensuring you receive the best value for your investment. In an ever-evolving industrial space, staying well-informed about emerging trends and advancements in valve technology can provide a competitive edge. Awareness of regulatory updates, new materials, and innovation in smart valve technologies will aid in anticipating market shifts and making strategic purchases aligned with future operational needs. Ultimately, understanding the intricate dynamics behind the pricing of a 6-inch butterfly valve allows decision-makers to prioritize elements that contribute to operational effectiveness, ensuring both fiscal responsibility and product performance are achieved.

Latest news

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

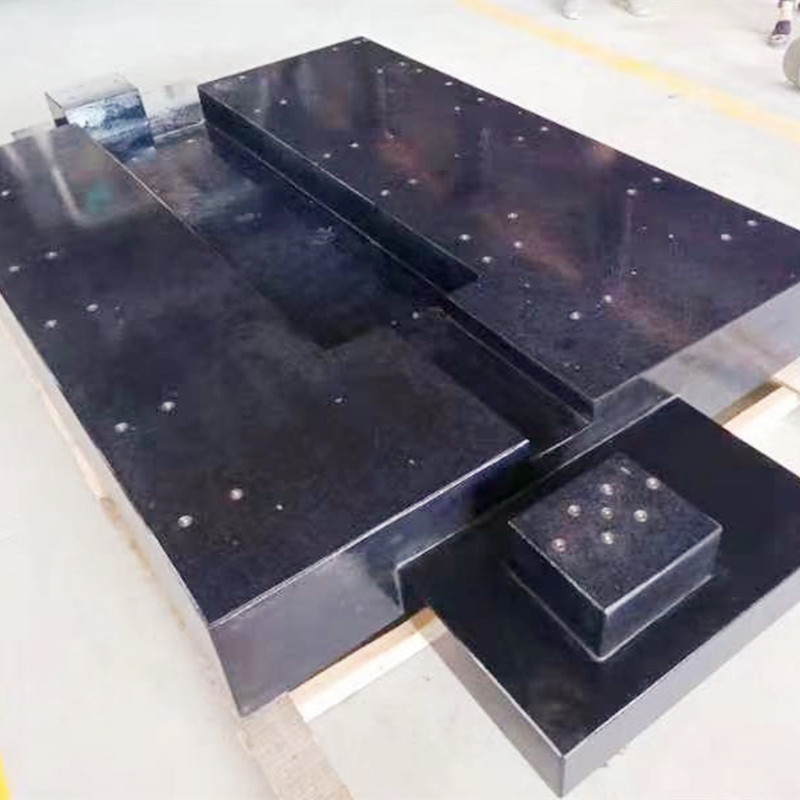

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS