okt . 02, 2024 08:57 Back to list

Alternative Designs for Piston Check Valve Applications and Efficiency Improvements

Understanding Piston Check Valves Design, Function, and Applications

Piston check valves are crucial components in various fluid systems, functioning primarily to ensure that fluid flows in one direction while preventing backflow. Their unique design and operational mechanics make them suitable for a range of applications across different industries. In this article, we will delve into the workings of piston check valves, their benefits, and their common applications.

Design and Mechanism

At the core of a piston check valve is the piston itself. This component is often made from durable materials, such as stainless steel or plastic, allowing it to withstand high pressures and corrosive environments. The primary function of the piston is to move up and down within the valve body, responding to changes in fluid pressure.

When fluid flows in the designated direction, it applies pressure on the underside of the piston, lifting it away from the seat and allowing flow to pass through. This design minimizes turbulence and pressure drop, making piston check valves more efficient than some other types of check valves. When the flow stops or reverses, the piston is pushed back down by gravity or the return flow pressure, sealing the opening and preventing any backflow. This automatic closing mechanism is crucial for preventing potential damage to pumps and other system components caused by reverse flow.

Advantages of Piston Check Valves

One of the primary advantages of piston check valves is their ability to effectively prevent backflow

. This feature is essential in applications where reverse flow could lead to contamination or damage, such as in the oil and gas industry, water treatment facilities, and chemical processing.Another significant benefit is their high flow capacity. Due to the streamlined design and the use of pistons, these valves can accommodate larger volumes of fluid compared to traditional flap or swing check valves. This quality is particularly advantageous in systems requiring high flow rates, such as fire protection systems and HVAC applications.

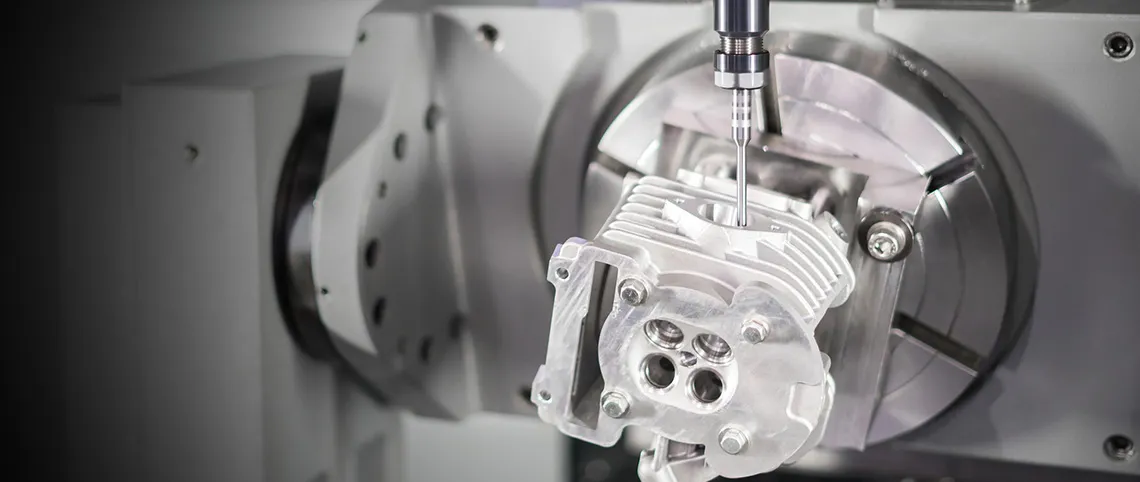

piston check valve

Additionally, piston check valves exhibit low noise levels and vibration due to their design. This is a crucial factor in systems where noise reduction is important, such as in commercial buildings and residential plumbing.

Applications of Piston Check Valves

Piston check valves are employed across various industries for their efficiency and reliability. In the water and wastewater treatment sector, they are used to prevent backflow that could contaminate clean water supplies. Similarly, the oil and gas industry relies on piston check valves to protect pipeline systems from backflow that could potentially cause spills or leaks.

In the HVAC industry, these valves play a significant role in maintaining system integrity by preventing refrigerant from flowing backward, which could disrupt operations. Additionally, they are commonly found in pump systems to ensure that the pumps function correctly without suffering damage from reverse flow.

Moreover, piston check valves are used in pharmaceutical and food processing applications, where maintaining the purity of the fluids is critical. Their ability to provide reliable sealing without requiring a significant amount of force to open or close makes them suitable for these sensitive applications.

Conclusion

In summary, piston check valves are essential components in various fluid systems, providing significant benefits such as preventing backflow, ensuring high flow capacities, and reducing noise levels. Their design and operational efficiency make them indispensable in industries ranging from water treatment to oil and gas, HVAC, and beyond. Understanding the mechanisms and applications of piston check valves enables engineers and designers to enhance the reliability and safety of fluid systems, ensuring optimal functionality across diverse sectors. As industries continue to evolve, the role of piston check valves will remain critical in maintaining the integrity and performance of fluid handling systems.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS