nov . 11, 2024 00:57 Back to list

Understanding the Importance of 6h Thread Gauge in Precision Engineering Applications

Understanding the 6H Thread Gauge A Key Component in Precision Engineering

Thread gauges play a crucial role in precision engineering, serving as an essential tool for measuring the accuracy and quality of various threaded components. Among these, the 6H thread gauge is particularly important due to its widespread application in manufacturing and mechanical engineering. This article will delve into the significance, specifications, and applications of the 6H thread gauge, highlighting why it is indispensable in ensuring the reliability of threaded connections.

What is a 6H Thread Gauge?

The term 6H refers to a specific class of fit within the international standard for metric threads, defined by the ISO (International Organization for Standardization). In thread classification, the number denotes the position of the thread in the tolerance zones, while the letter signifies the type of fit. The H indicates that the internal thread is the major diameter, which is fundamental in determining how well two threaded components will mate. Specifically, a 6H gauge indicates a medium tolerance fit, offering a balance between ease of assembly and sufficient strength for load-bearing applications.

Specifications and Tolerances

Understanding the specifications of the 6H thread gauge is vital for engineers and manufacturers alike. The 6H fit allows for a tolerance range that is typically broader compared to tighter fits, such as 6G. This means that while a 6H thread may not be as precise, it compensates with greater flexibility, making it suitable for a variety of applications where perfect alignment is not critical.

The tolerance for a 6H thread gauge can be expressed in micrometers and is derived based on the nominal diameter of the thread. For example, for an M10 thread (10 mm diameter), the tolerance may be around ±0.15 mm. Such tolerances are essential in ensuring that threaded parts can be manufactured and assembled efficiently while maintaining a level of reliability essential for safety and performance.

Applications of 6H Thread Gauges

6h thread gauge

The versatile nature of the 6H thread gauge allows it to be used in many different sectors. It is particularly prevalent in automotive, aerospace, and machinery manufacturing. In these industries, components subjected to vibrations, thermal expansion, and different environmental factors often rely on thread gauges to facilitate stable connections.

Moreover, the 6H thread gauge is crucial in scenarios where parts must be interchangeable. With its standardized tolerance, engineers can ensure that products can be produced in different batches without compromising quality. For example, a bolt made with a 6H internal thread can be paired with a nut of the same classification, ensuring compatibility and reducing the risk of assembly issues.

Quality Assurance and Testing

Quality assurance in manufacturing threaded parts is vital for performance and safety. The use of the 6H thread gauge contributes significantly to this process. By employing this gauge, manufacturers can check that their produced components meet the necessary specifications before they are assembled into larger systems. This not only ensures the reliability of individual parts but also the overall integrity of the final product.

In addition to manual inspections, modern manufacturing techniques often incorporate automated gauge systems that employ 6H thread gauges, allowing for higher precision and faster production rates. By embracing technology, manufacturers can achieve consistent quality and reduce human error, ultimately enhancing product reliability.

Conclusion

In summary, the 6H thread gauge is an indispensable tool in the world of precision engineering. Its unique balance of tolerances, wide-ranging applications, and pivotal role in quality assurance practices make it essential for the production of reliable and efficient threaded components. As industries continue to evolve and demand higher standards, the significance of tools like the 6H thread gauge will only increase, underlining its importance in the future of manufacturing and engineering practices.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

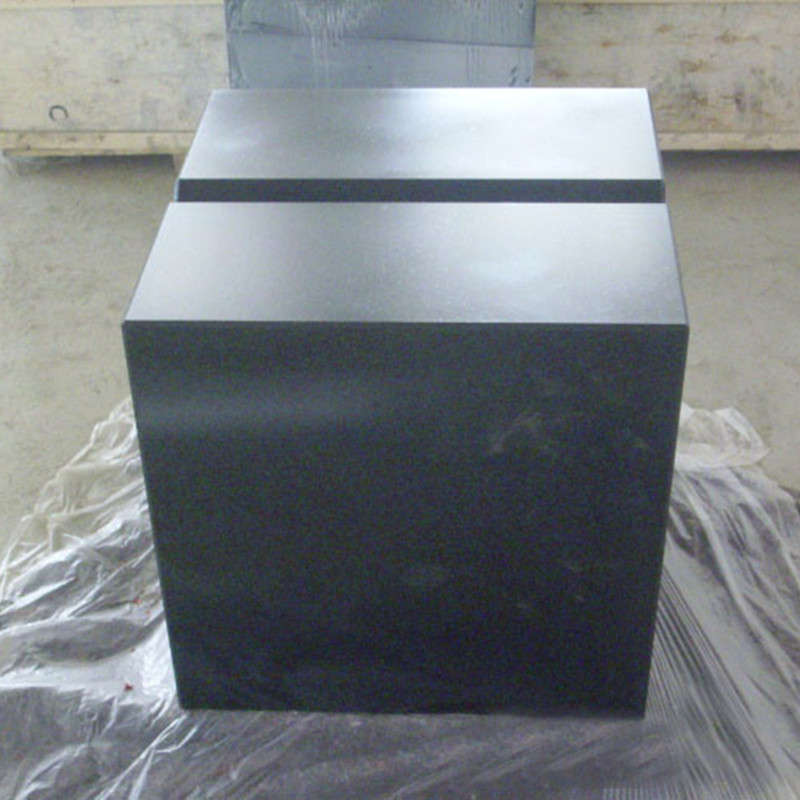

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS