සැප්. . 04, 2024 12:50 Back to list

non slam check valve

Understanding Non-Slam Check Valves Importance and Applications

Non-slam check valves are critical components in various industrial systems, serving to prevent backflow while minimizing water hammer, a common issue in piping systems. Water hammer occurs when a fluid in motion is forced to stop or change direction abruptly, creating shock waves that can damage pipes, fittings, and equipment. Non-slam check valves are designed to address this challenge by employing a mechanism that allows for smoother operation, reducing the potential for these destructive pressure surges.

Understanding Non-Slam Check Valves Importance and Applications

The functioning of a non-slam check valve is often facilitated by a combination of buoyancy and a hydraulic force that keeps the valve open during normal flow conditions. As the flow decreases or changes direction, the valve gently closes in response to the dynamic conditions of the fluid. This operational modality contributes substantially to the longevity and performance of piping systems, making these valves an essential choice for industries that rely on the efficient management of fluids.

non slam check valve

Applications of non-slam check valves span a wide range of sectors, including water and wastewater treatment, oil and gas, power generation, and HVAC systems. In wastewater treatment plants, for example, preventing backflow is crucial to avoid contamination of clean water supplies. In oil and gas applications, these valves help maintain the integrity of pipelines by ensuring that fluids only flow in designated directions, thus protecting against spills and leaks.

Moreover, the choice of material and design for non-slam check valves is crucial for specific applications. They can be constructed from various materials, including stainless steel, brass, or thermoplastics, depending on factors such as temperature, pressure, and the nature of the fluid being transported. The design must also accommodate installation requirements, with options for horizontal or vertical orientations, allowing for flexibility in system configurations.

Furthermore, maintenance considerations are an important aspect of the use of non-slam check valves. While these valves are generally low-maintenance, ensuring that they are free from debris and functioning correctly is vital for their long-term performance. Regular inspections will help identify wear and tear and any potential operational issues, thereby extending the lifespan of the valve and the entire system.

In conclusion, non-slam check valves are indispensable in modern fluid handling systems. Their ability to prevent backflow while minimizing pressure surges contributes to enhanced system reliability and efficiency. As industries continue to evolve, the role of these valves becomes more significant, underscoring the need for engineers and operators to understand their function and applications thoroughly. Investing in high-quality non-slam check valves can lead to significant long-term savings, reduced system downtime, and improved overall performance in various industrial environments.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

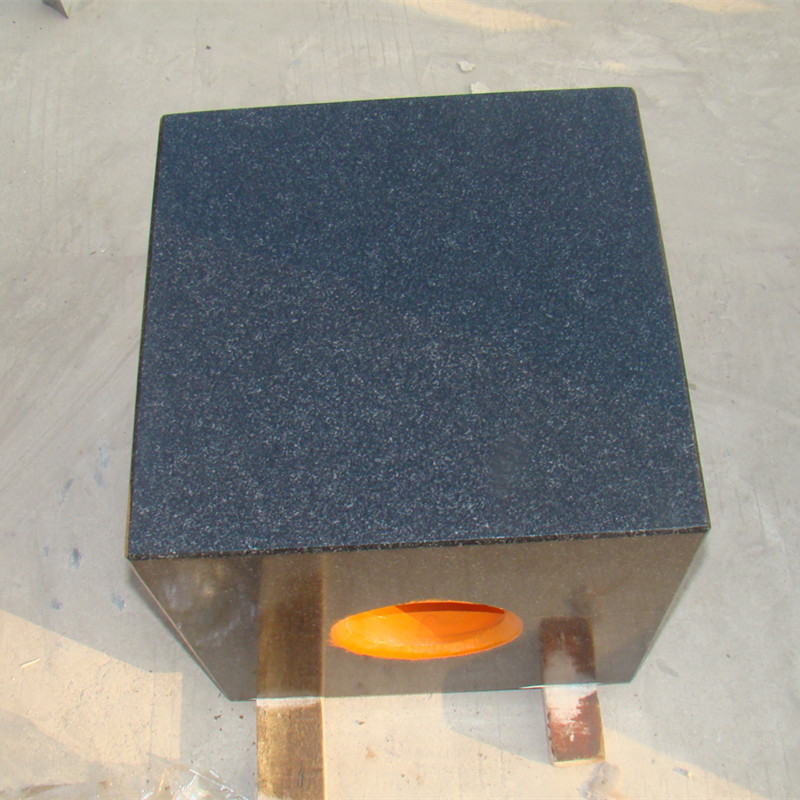

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS