ජූලි . 07, 2025 11:01 ලැයිස්තුවට ආපසු

Correct Calibration Methods for 90 Degree Angle Tools

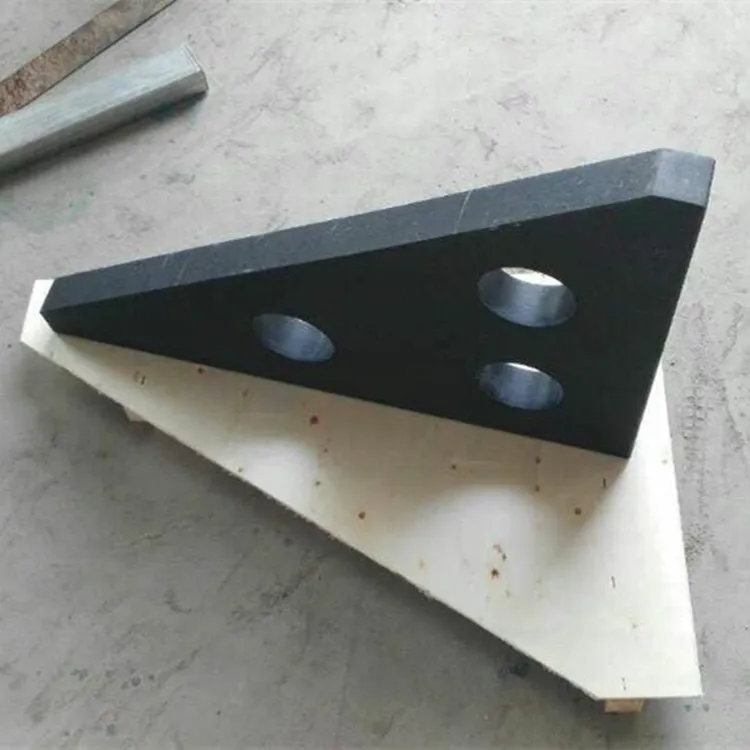

In the field of precision measurement and manufacturing, accurate 90 - degree angle tools are indispensable for ensuring the quality and precision of workpieces. Storaen (Cangzhou) International Trading Co. recognizes the significance of proper calibration for tools like right angle rulers, 90 degree angle rulers, and right angle protractors.

Magnesium Aluminum Alloy Right Angle Ruler Properties Table

|

Property |

විස්තර |

|

Alternative Name |

Right angle compass (in some situations) |

|

Main Function |

Detect the verticality of the workpiece, check the verticality of the relative position of the workpiece, used for marking |

|

Industry Application |

Important in the mechanical industry for verticality inspection, installation, processing, positioning, and marking of machine tools, mechanical equipment, and components |

|

Material Advantage |

Recommended by scientific research and metrology departments, used to produce lightweight flat rulers with great advantages |

|

Tensile Strength |

47kg/mm² |

|

Elongation |

17 |

|

Bending Point |

110kg/mm² |

|

Vickers Strength |

HV80 |

Understanding the Right Angle Ruler

- A right angle ruler, such as those made of magnesium aluminum alloy supplied by Storaen (Cangzhou) International Trading Co., is a fundamental tool in the mechanical industry. It serves multiple purposes, including detecting the verticality of workpieces, ensuring the correct vertical relative position between different parts, and even for marking during the manufacturing process.

- The accuracy of a right angle ruler directly impacts the quality of the final product. Even a slight deviation from the perfect 90 - degree angle can lead to significant errors in assembly, installation, or machining. For example, in the construction of complex mechanical equipment, an inaccurate right angle ruler can cause components to fit poorly, reducing the overall performance and lifespan of the equipment.

- Storaen (Cangzhou) International Trading Co.'s magnesium aluminum alloy right angle rulersoffer unique advantages. Their lightweight nature, thanks to the material properties, makes them easy to handle, while their high tensile strength (47kg/mm²), elongation (17), bending point (110kg/mm²), and Vickers strength (HV80) ensure durability and long - term accuracy.

Pre - Calibration Preparations for 90 Degree Angle Ruler

- Inspect the Tool: Thoroughly examine the 90 degree angle rulerfor any visible damage, such as cracks, bends, or scratches. Even minor surface imperfections can affect the accuracy of angle measurement. If any damage is detected, determine whether the tool can be repaired or if it needs to be replaced.

- Clean the Ruler: Use a soft, clean cloth to remove any dirt, dust, or debris from the surfaces of the 90 degree angle ruler. Contaminants on the ruler can interfere with the calibration process and lead to inaccurate results. Special attention should be paid to the edges and corners where dirt may accumulate.

- Prepare the Calibration Environment: Select a stable, flat, and vibration - free surface for calibration. The environment should also have a consistent temperature, as temperature fluctuations can cause the magnesium aluminum alloy material to expand or contract slightly, affecting the angle accuracy. Additionally, gather any necessary reference tools, such as a high - precision calibrated right angle protractoror a known - accurate right - angled surface.

Calibration Process for Right Angle Protractor

- Initial Comparison: Place the right angle protractoragainst a reference right - angled surface or another high - precision right angle ruler. Align the edges as precisely as possible and observe any gaps or misalignments. If the right angle protractor is accurate, there should be no visible space between the tool and the reference at the 90 - degree angle.

- Adjustment (if necessary): For some right angle protractors, there may be adjustable components. If a deviation from the 90 - degree angle is detected during the initial comparison, use the appropriate tools (such as small wrenches or screwdrivers) to make the necessary adjustments. Slowly and carefully adjust the angle until it aligns perfectly with the reference. After each adjustment, repeat the comparison process to check the accuracy.

- Verification: Once the adjustment is complete, perform multiple checks from different angles and positions. Place the right angle protractoron various workpieces or surfaces to ensure that the calibrated 90 - degree angle holds true consistently. This verification step is crucial to confirm that the calibration is accurate and reliable.

Right Angle Ruler FAQS

How often should a 90 degree angle ruler be calibrated?

The calibration frequency of a 90 degree angle ruler depends on its usage. In high - precision manufacturing processes where accuracy is critical, it may need to be calibrated weekly or monthly. For general mechanical work or less demanding applications, quarterly or semi - annual calibration can be sufficient. Storaen (Cangzhou) International Trading Co. advises clients to assess the specific usage conditions and requirements to determine the most appropriate calibration schedule.

Can a damaged right angle protractor be recalibrated?

It depends on the nature and extent of the damage. Minor damages, such as small scratches or misalignments that do not affect the structural integrity, may be repairable and can be calibrated after proper repair. However, if the right angle protractor has suffered significant damage, like a cracked frame or a severely bent arm, it may be difficult or impossible to calibrate accurately, and replacement may be necessary. Storaen (Cangzhou) International Trading Co. can provide guidance on assessing the repairability of damaged tools.

What factors can affect the calibration accuracy of a right angle ruler?

Several factors can impact the calibration accuracy of a right angle ruler. Environmental factors such as temperature and humidity changes can cause the magnesium aluminum alloy material to expand or contract, altering the angle. Rough handling, dropping, or improper storage can lead to physical damage and misalignment. Additionally, the presence of dirt, debris, or corrosion on the ruler's surfaces can interfere with accurate measurement and calibration.

Is it possible to calibrate a right angle protractor on - site?

Yes, it is possible to calibrate a right angle protractor on - site, provided that the necessary reference tools and a suitable calibration environment are available. However, for highly accurate calibration, especially in cases where extreme precision is required, it may be more advisable to send the tool to a professional calibration laboratory. Storaen (Cangzhou) International Trading Co. can offer advice on the best calibration approach based on the specific needs of clients.

How can wholesalers ensure clients receive properly calibrated right angle rulers?

Wholesalers like Storaen (Cangzhou) International Trading Co. can implement strict pre - shipment calibration checks for all right angle rulers, 90 degree angle rulers, and right angle protractors. They can use high - precision reference tools and follow standardized calibration procedures. Additionally, providing clients with detailed calibration certificates, usage instructions, and guidelines for regular recalibration helps ensure that the tools remain accurate in the long run. Offering after - sales support and access to calibration services further enhances customer satisfaction and the reliability of the products.

-

thread-plug-gauge-our-promise-of-measurement-excellenceපුවත්Aug.22,2025

-

gauge-pin-class-reflecting-quality-legacyපුවත්Aug.22,2025

-

check-valve-types-for-high-rise-buildingsපුවත්Aug.22,2025

-

water-control-valve-for-irrigation-systemsපුවත්Aug.22,2025

-

gate-valve-with-soft-seal-technologyපුවත්Aug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsපුවත්Aug.22,2025

ආශ්රිත නිෂ්පාදන