දෙසැ. . 23, 2024 06:43 Back to list

Affordable Welding Tables for Every DIY Enthusiast and Professional Welder

Creating a Cost-Effective Welding Table A Practical Guide

Welding is an essential skill for many trades and hobbies, from metal fabrication to DIY projects. The success of any welding task often hinges on a sturdy, reliable work surface. A good welding table is crucial for achieving precise welds, but purchasing one can be expensive. Fortunately, it is entirely possible to create a cheap welding table that meets your needs without breaking the bank. This article will guide you through the process of designing and constructing a cost-effective welding table.

Why You Need a Welding Table

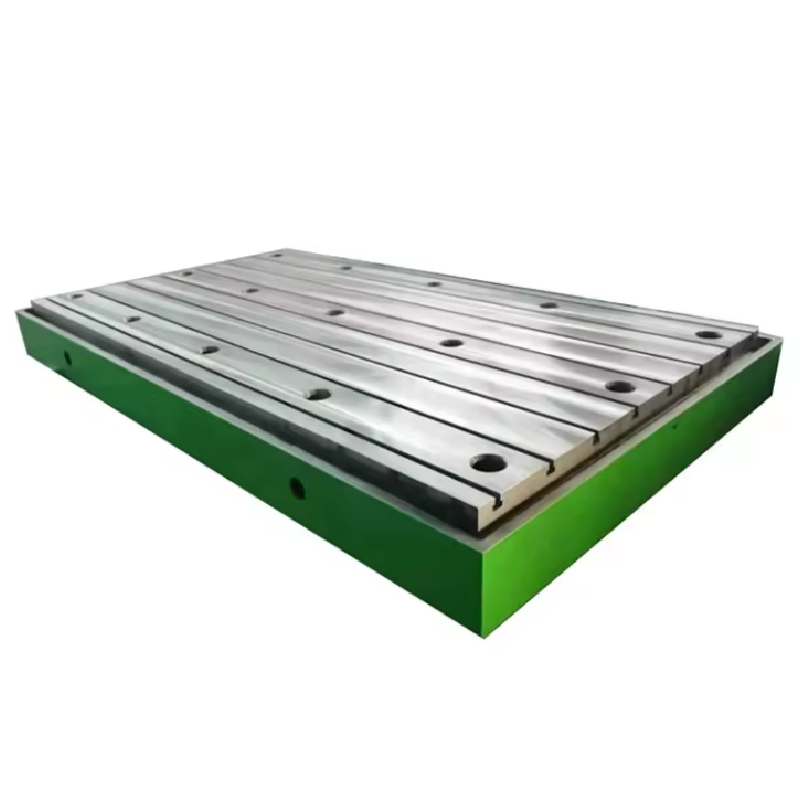

A welding table serves multiple purposes it provides a stable work surface, supports your materials, and ensures safety during the welding process. Good welding tables are usually made from thick steel or heavy-duty materials to withstand high temperatures and significant weight. They also feature a flat surface, which is essential for precise work. Without this critical piece of equipment, it can be challenging to achieve the quality of work you desire.

Materials Needed

To build a cheap welding table, you’ll need to gather some materials. Here’s a basic list to get you started

1. Work Surface Material Steel plate is preferred, but for a budget-friendly option, you might consider using a repurposed metal sheet or even a thick piece of plywood as a temporary workaround. 2. Frame Material You can use square tubing, angle iron, or even reclaimed metal from old furniture or equipment. 3. Legs These can be made from the same material as the frame, or you can use heavy-duty caster wheels if you want a mobile table. 4. Welding Equipment Obviously, you’ll need a welder, but make sure you have clamps, angle grinders, and safety gear on hand too. 5. Fasteners and Miscellaneous Supplies Beads of welding wire, nuts, bolts, or other materials might also be needed based on your specific design.

Step-by-Step Construction Guide

1

. Planning and DesignBegin by sketching out your design. Determine the dimensions based on your workspace and the size of the projects you’ll be working on. A standard size is around 4 feet by 2 feet, but you can adjust it according to your needs. Ensure that the height is comfortable for your working style, typically around 30 to 36 inches.

2. Gathering Materials

cheap welding table

After planning, gather your materials. Check local scrap yards or online marketplaces for used metal; you may find suitable materials at a fraction of the cost. Don’t overlook local classifieds or community forums where people sell or give away metal pieces.

3. Constructing the Frame

Start with the frame. Cut your square tubing to the desired length and assemble it into a rectangular shape. Use a welder to join the corners securely. Square up the frame by measuring diagonally from corner to corner, adjusting as necessary until it’s even.

4. Adding the Legs

Attach the legs to the frame. Make sure they are stable and can support the weight of your materials and equipment. If you opted for caster wheels for mobility, now is the time to install them. Ensure that any casters have locking mechanisms to keep the table stable while you work.

5. Mounting the Surface

Once the frame is securely assembled, it’s time to attach the working surface. If you are using a metal sheet, weld or bolt it down securely. If you're using plywood for a temporary solution, ensure that it is thick enough to withstand the pressure and heat from welding.

6. Finishing Touches

Finally, inspect your table for any sharp edges or loose parts. Sand down any rough spots, and consider applying a coat of rust-resistant paint if you’ve used raw metal. Ensure that everything is securely fastened and safe for use.

Conclusion

Building a cheap welding table doesn’t have to be a daunting task. With some creativity and resourcefulness, you can create a functional and durable workspace tailored to your needs without incurring significant costs. Remember, the key to a successful weld lies not only in technique but also in having a reliable and sturdy work surface. With your new table, you’ll be ready to tackle welding projects with confidence and ease. Happy welding!

-

Water Valve Gate Design Prevents Leakage and CorrosionNewsJul.11,2025

-

Steel Fab Table Features Reinforced Construction for LongevityNewsJul.11,2025

-

Specialized Valve Designs for High Pressure SystemsNewsJul.11,2025

-

Machinist Gauge Pins Feature Ground and Lapped FinishesNewsJul.11,2025

-

Hose Check Valve Prevents Backflow in Irrigation LinesNewsJul.11,2025

-

Durable Micrometer Tools Withstand Heavy Workshop UseNewsJul.11,2025

Related PRODUCTS