آپٽيڪل جامع تصويري سطح

پيداوار جي وضاحت

- 1. ايپليڪيشن

آپٽيڪل جامع تصوير جي سطح وڏي پيماني تي استعمال ڪيو ويندو آهي گريجوئيٽ جي سطح جي سطح ۽ سلنڊر سطح جي افقي طرف کي ماپڻ ۾؛ سلائيڊ وي يا مشين ٽول جي بيس يا آپٽيڪل ميخانياتي اوزار جي جهاز جي جوڙجڪ ۽ سڌو سنئون ۽ گڏوگڏ سامان جي نصب ڪرڻ جي پوزيشن جي صحيحيت.

- 2. ٽيڪنيڪل ڊيٽا

(1) هر گريجوئيشن قدر: ...0.01mm/m

(2) وڌ ۾ وڌ ماپ جي حد: ...0 ~ 10mm / م

(3) الائونس: ...1mm/هڪ ميٽر جي اندر...0.01mm/m

پوري ماپ جي حد اندر...0.02mm/m

(4) ڪم ڪندڙ مٿاڇري تي جهاز جي انحراف...0.0003mm/m

(5) روح جي سطح جي هر گريجوئيشن قدر...0.1mm/m

(6) ڪم ڪندڙ مٿاڇري (LW): ...165 48mm

(7) اوزار جو خالص وزن: ...2kgs.

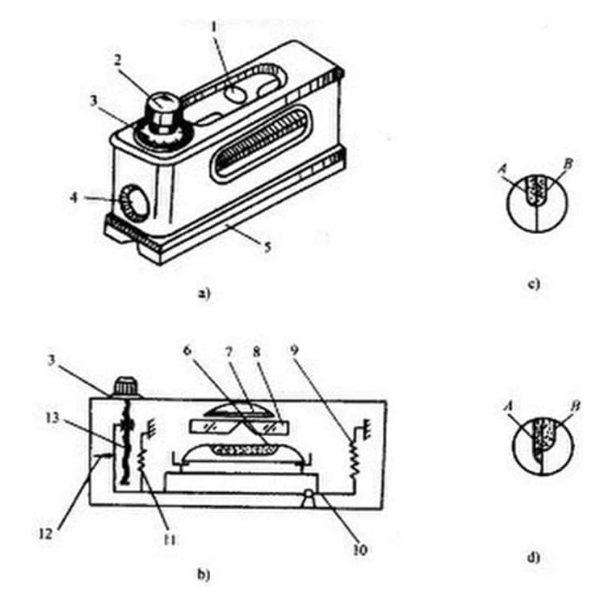

- 3. اوزار جي جوڙجڪ:

جامع تصويري سطح ۾ بنيادي طور تي ھيٺين حصن تي مشتمل آھي جھڙوڪ مائيڪرو ايڊجسٽ ڪرڻ وارو اسڪرو، نٽ، گريجوئيٽ ڊسڪ، اسپرٽ ليول، پرزم، ميگنيفائينگ گلاس، ليور ۽ گڏوگڏ بيس سان گڏ سادو ۽ وي ڪم ڪندڙ سطح.

- 4. ڪم جو اصول:

جامع تصويري سطح پرزم استعمال ڪري ٿي فضائي بلبل جي تصويرن کي روح جي سطح ۾ جامع ۽ ميگنيفائيڊ پڙهڻ جي درستگي کي وڌائڻ لاءِ ۽ پڙهڻ جي حساسيت کي وڌائڻ لاءِ ليور ۽ مائڪرو اسڪرو ٽرانسميٽنگ سسٽم استعمال ڪري ٿي. تنهن ڪري جيڪڏهن ڪم جو ٽڪرو 0.01mm/m جي گريڊينٽ سان، اهو جامع تصويري سطح ۾ صحيح طور تي پڙهي سگهجي ٿو (جامع تصوير جي سطح ۾ روح جي سطح بنيادي طور تي صفر کي اشارو ڪرڻ جو ڪردار ادا ڪري ٿو).

- 5. آپريٽنگ جو طريقو:

ماپڻ واري ڪم جي پيس جي ڪم ڪندڙ سطح تي جامع تصوير جي سطح کي جاء ڏيو ۽ ماپنگ واري ڪم پيس جي گريجوئيٽ کي ٽو ايئر بلبل جي تصويرن جي اڻڄاتل سبب بڻائي ٿي؛ گريجوئيٽ ڊسڪ کي گھمايو جيستائين ٽو ايئر بلبل تصويرون گڏ ٿين ۽ پڙھڻ کي فوري طور تي حاصل ڪري سگھجي. ماپڻ واري ڪم جي اصل درجي جو اندازو هيٺين فارمولا ذريعي ڪري سگهجي ٿو:

اصل گرڊيئينٽ = گرڊيئينٽ ويل فولڪرم فاصلو ڊسڪ ريڊنگ

فاکس مثال: ڊسڪ ريڊنگ: 5 گريڊينٽ؛ جيئن ته هن جامع تصويري سطح کي ان جي گريڊيئنٽ ويليو ۽ فلڪرم جي فاصلي سان جڙيل آهي، يعني گريڊيئينٽ ويليو: 0.01mm/m ۽ فلڪرم فاصلو: 165mm.

تنهن ڪري: حقيقي گريجوئيٽ = 165mm 5 0.01/1000=0.00825mm

- 6. آپريشن نوٽيس:

(1) استعمال ڪرڻ کان اڳ، تيل جي مٽي کي گيسولين سان صاف ڪريو ۽ پوءِ جاذب گوج سان صاف ڪريو.

(2) حرارت جي تبديلي جو اوزار تي وڏو اثر پوي ٿو ۽ ان ڪري ان کي گرميءَ جي ماخذ سان الڳ ڪيو وڃي ته جيئن غلطي نه ٿئي.

(3) ماپ ڪرڻ دوران، گريجوئيٽ ڊسڪ کي گھمايو جيستائين ٽو ايئر بلبل جون تصويرون مڪمل طور تي ٺھيل نه ٿين ۽ پوءِ پڙھڻ کي مثبت ۽ منفي ٻنهي طرفن تي وٺي سگھجي ٿو.

(4) If the instrument is found with in correct zero position, it may be adjusted; Put the instrument on a stable table and rotate the graduated disc to set the tow air bubble images coincide to get first reading a; Then turn the instrument by 180o and put back to its original place. Ra-rotate the graduated disc to get the tow air bubbles coincide to get the second reading b. So 1/2 (α +β ) is the zero deviation of the instrument. Loosen the three supporting screws on the graduated disc and press lightly by hand the embossed adjusting cap; Rotate the disc by 1/2 (α +β) to get the zero deviation and the point line composite; At last fasten the screws.

(5) ڪم ڪرڻ کان پوءِ، اوزار جي ڪم ڪندڙ مٿاڇري کي صاف ڪيو وڃي ۽ تيزاب کان پاڪ، اينهائيڊروس، اينٽي رسٽ آئل ۽ اينٽي رسٽ پيپر سان گڏ ڪيو وڃي. ان کي ڪاٺ جي دٻي ۾ وجھو ۽ پوء ان کي صاف سڪل جاء تي ذخيرو ڪريو.

Hot Tags: Optical Composite Image Level Optical Composite Image Level suppliers China Optical Composite Image Level Optical Composite Image Level factory stable Optical Composite Image Level

پيداوار جي ماپ

ٽيڪنيڪل پيراگراف

- پليٽ ويليو ڊائل 0.01 mm/m

- ماپ جي حد 0-10 ملي ميٽر / ميٽر

- Parent-child error within ± 1mm/m+0.01 mm/m

- The parental error within the entire measurement range is ± 0. 02 millimeters/meter

- 0.003mm جي بينچ فليٽ انحراف

- سيل جي قيمت جمع ڪرڻ جو معيار 0.1 ملي ميٽر / ميٽر

- آفيس ڊيسڪ سائيز 165 x 48 ملي ميٽر

- خالص وزن 2.2 ڪلوگرام

Optical Composite Image Level Maintenance: Antirust Oil & Storage Tips

Proper maintenance ensures your optical composite image level retains its 0.01mm/m precision and durability. Follow these steps to protect its prism technology and mechanical components:

1. Daily Cleaning for Surface Protection

After use, wipe working surfaces (V-groove, edges, lenses) with isopropyl alcohol on a lint-free cloth to remove oils and dust. Use a soft brush for stubborn debris—never abrasives, which can scratch optical parts or damage metal coatings. This preserves the precision ground surfaces (Ra ≤ 0.1μm) critical for accurate readings.

2. Routine Antirust Care for Metal Parts

While the granite base resists corrosion, metal components (screws, levers, hinges) need protection. Apply Storaen’s non-acidic anti-rust oil every 3 months or after moisture exposure:

Apply thinly to threads and pivots with a dropper, avoiding pooling on granite/lenses.

Prevents seizing: Maintains lever mechanism sensitivity (0.001mm precision) for cylindrical slope measurements.

3. Optimal Storage Practices

Store in the included hard case or a dry cabinet to avoid temperature/humidity damage:

Environment: 10°C–30°C, <60% humidity to prevent lens condensation and optical distortion.

Positioning: Lay flat or upright in padded slots; never under heavy objects to avoid misaligning the optical system.

Long-term storage: Reapply anti-rust oil and add a silica packet; inspect 24 hours before use, verifying zero position via 180° rotation calibration.

4. Monthly Functional Inspections

Check performance regularly to ensure reliability:

Bubble clarity: Confirm the composite bubble image aligns smoothly without blur.

Lever movement: Test micro-screws for smooth rotation—stiffness signals needed lubrication.

Flatness check: Use a reference plate to validate factory-calibrated flatness (±0.0003mm/m).

5. Storaen’s Support for Longevity

Leverage our expert services to maintain peak performance:

Factory recalibration: Restores 0.01mm/m precision via ISO-certified equipment for critical applications.

Genuine parts: Replacement components ensure compatibility and preserve original accuracy.

By following these steps, your Storaen optical composite image level will deliver consistent precision for industrial alignment tasks, backed by our 30+ years of engineering expertise.

Zero Position Calibration of Optical Composite Image Level: 180° Rotation Method Explained

Accurate zero calibration is vital for your Storaen optical composite image level to maintain its 0.01mm/m precision and ±0.0003mm/m flatness. The 180° rotation method eliminates subtle optical or mechanical shifts, ensuring reliable measurements in critical tasks like CNC machine alignment or aerospace component inspection. Here’s a streamlined, step-by-step guide:

1. Why Calibrate?

Impacts, vibrations, or temperature fluctuations can shift the level’s zero reference, leading to measurement drift. Calibration realigns the bubble vial with the tool’s optical prism and lever system, ensuring consistent baselines for industrial applications where 0.001mm deviations are unacceptable—such as verifying machine tool guides or structural frameworks.

2. Setup Requirements

Storaen optical composite image level (featuring a V-grooved base and micro-adjusting screw)

Certified precision reference flat (e.g., our Storaen granite surface plate, with flatness ≤0.0002mm/m)

A clean, vibration-free workbench in a temperature-stabilized environment (18°C–22°C recommended)

3. Step 1: Initial Measurement

Place the level lengthwise on the reference flat, aligning the V-grooved base with the flat’s central axis. Rotate the micro-adjusting screw until the composite bubble image—created by the 45° prism system—perfectly overlaps in the viewfinder. Record this initial scale reading (A), which reflects the current deviation from true zero.

4. Step 2: 180° Rotation & Second Reading

Carefully flip the level 180° end-to-end while maintaining its longitudinal orientation on the flat (avoid any lateral movement). Adjust the micro-screw again to align the bubble image and record the new reading (B). The difference Δ = |A - B| indicates zero position error; ideal values for Storaen levels should be ≤0.005mm/m.

5. Step 3: Error Correction & Verification

Calculate the target zero position as the midpoint: C = (A + B)/2. Loosen the protective cap on the zero-adjustment screw (typically located near the bubble vial), rotate the screw until the scale reads C, then retighten. Repeat Steps 3–4 until Δ ≤0.002mm/m, ensuring minimal residual error.

6. Pro Tips for Precision

Triple-Check Consistency: Perform 3 calibration cycles, especially after transporting the level or working in environments with temperature swings, to ensure repeatable results.

Lubricate Moving Parts: Apply a drop of Storaen’s non-acidic oil to the micro-screw before adjustment to ensure smooth, backlash-free operation and prevent binding.

Environmental Control: Avoid calibrating near heat sources or drafts, as even minor temperature gradients can affect the granite base’s dimensional stability and introduce errors.

7. Storaen’s Calibration Support

Every Storaen optical composite image level includes a NIST-traceable calibration certificate, but quarterly in-field checks are recommended for heavy use. Our support includes:

Factory Recalibration: Restoring original 0.01mm/m accuracy using laser interferometers for high-stakes applications.

Genuine Spare Parts: Readily available adjustment screws and maintenance kits for long-term usability.

Video Tutorials & Expert Guidance: Step-by-step videos and engineer support to assist with on-site calibration procedures.

Final Notes

Mastering the 180° rotation method ensures your Storaen optical composite image level delivers the precision required for cylindrical slope measurements, machine tool flatness checks, and other critical alignments. With proper calibration, this tool, backed by our 30+ years of engineering expertise, becomes an indispensable asset in your quality control workflow, ensuring every measurement is as reliable as the first.

لاڳاپيل پروڊڪٽس

لاڳاپيل خبرون

Precision Manufacturing with Advanced Spline Gauge Design

As a leading wholesale supplier in the precision measurement industry, Storaen (Cangzhou) International Trading Co. understands the critical role that Spline Gauges play in ensuring manufacturing accuracy.

Industrial-Grade Calibrated Pin Gauges for Exact Measurements

For precision-driven manufacturers, our Calibrated Pin Gauges deliver unmatched accuracy in dimensional verification.

Industrial Filtration Systems Depend on Quality Filter DN50 Solutions

In modern industrial operations, effective filtration plays a vital role in protecting equipment and ensuring smooth processes.