Nov . 16, 2024 10:48 Back to list

anti vibration pads industrial

The Importance of Anti-Vibration Pads in Industrial Applications

In today’s fast-paced industrial environment, machinery plays a pivotal role in production efficiency and operational effectiveness. However, the functionality of these machines can be compromised by unwanted vibrations. To mitigate this issue, anti-vibration pads have emerged as a vital component within various industrial settings.

Understanding Vibration in Industrial Equipment

Vibrations in industrial equipment can stem from numerous sources, including rotating components, unbalanced machinery, or external influences like traffic or nearby machinery. These vibrations can lead to significant challenges such as accelerated wear and tear, operational inefficiencies, and even catastrophic failures over time. In critical industries, these vibrations can adversely affect product quality, operational safety, and employee comfort, emphasizing the need for effective vibration control measures.

What Are Anti-Vibration Pads?

Anti-vibration pads are specialized materials designed to absorb vibrations and isolate the machinery from its surrounding environment. Typically made from rubber, neoprene, or other elastomeric compounds, these pads act as dampers that absorb excess energy produced by vibrations. They can be employed in various applications, from supporting heavy machinery and HVAC systems to reducing noise and increasing stability in sensitive electronic equipment.

Benefits of Using Anti-Vibration Pads

1. Enhanced Equipment Longevity One of the most significant advantages of using anti-vibration pads is their ability to extend the lifespan of industrial equipment. By minimizing the impact of vibrations, these pads help to prevent component fatigue and mechanical failures, resulting in lower maintenance costs and extended service intervals.

2. Improved Operational Efficiency Vibrations can hinder machinery performance and cause decreased efficiency. By utilizing anti-vibration pads, industries can ensure machinery operates as intended, thus enhancing overall productivity and reducing downtime.

3. Noise Reduction In many industrial settings, noise pollution can be a serious issue. Anti-vibration pads not only dampen vibrations but also help in reducing the noise generated by machinery. This improvement in sound levels can lead to a healthier working environment, enhancing employee satisfaction and productivity.

anti vibration pads industrial

4. Safety Enhancements High levels of vibration can lead to unstable machinery, posing safety risks to operators and nearby personnel. Anti-vibration pads provide a stable base for machinery, significantly reducing the risk of accidents or equipment-related injuries.

5. Environmental Benefits By reducing vibrations and noise, anti-vibration pads contribute to a more sustainable industrial environment. They decrease the impact of machinery on their surroundings, benefiting neighboring communities and ecosystems.

Selecting the Right Anti-Vibration Pads

When choosing anti-vibration pads for industrial applications, several factors should be considered

- Load Capacity Different pads have varying load capacities. It is crucial to select a pad that can support the weight of the equipment without compromising performance. - Type of Vibration Understanding the frequency and type of vibration generated by machinery is essential in selecting the most effective damping material.

- Environmental Factors Consider the specific conditions of the environment where the pads will be used, such as temperature, humidity, and exposure to chemicals.

- Durability The materials used in the pads should withstand the demanding conditions of the industrial environment to ensure long-term performance.

Conclusion

In conclusion, anti-vibration pads are essential tools in modern industrial applications. They provide multiple benefits, including enhanced equipment longevity, improved operational efficiency, reduced noise levels, increased safety, and environmental advantages. As industries continue to advance, the role of anti-vibration technologies will only become more significant, ensuring that machinery operates smoothly and efficiently while safeguarding the well-being of both people and the planet. Implementing the right anti-vibration solutions can lead to a more productive and sustainable industrial future.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

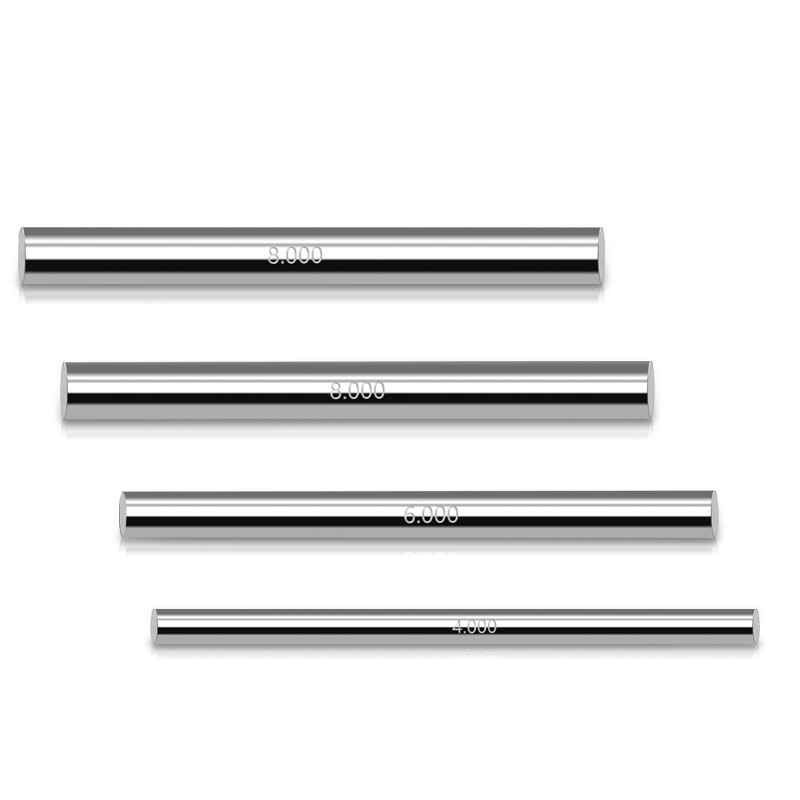

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS