Dec . 03, 2024 18:38 Back to list

3 gate valve

Understanding the 3% Gate Valve Functionality and Applications

In the realm of fluid control systems, valves play a crucial role in regulating the flow of liquids and gases. Among the various types of valves available, the gate valve stands out for its unique functionality and versatility. This article delves into the specifics of a gate valve, particularly one that operates at 3% capacity, exploring its design, operational principles, benefits, and applications.

What is a Gate Valve?

A gate valve is a type of linear valve used primarily to start or stop the flow of fluid. Unlike other valves that alter flow characteristics as they operate, a gate valve is designed to provide minimal flow resistance when fully open. Its mechanism consists of a gate—a flat disc that moves up and down within the valve body to regulate flow. When the gate is lifted, it creates a straight path for the fluid, ensuring a smooth and undisturbed flow.

The 3% Capacity Functionality

The term 3% gate valve refers to a specific operational capacity where the gate valve opens only 3% of its potential flow area. This feature allows for precise control of fluid flow, making it invaluable in applications where flow variations are critical. Operating a valve at such a small capacity is typically not meant for flow regulation but rather for maintaining system pressure, preventing backflow, or fine-tuning fluid dynamics in certain processes.

Design and Construction

Gate valves are typically constructed with robust materials like stainless steel, brass, or cast iron, ensuring durability and resistance to corrosion. The design includes several key components

- Body The main part of the valve that houses the gate. - Gate The movable component that blocks or allows flow. - Stem The mechanism that connects the gate to the actuator (manual handle or motor). - Sealing Mechanism Gaskets or O-rings that ensure a tight seal to prevent leaks.

For a 3% gate valve, these components must be engineered to provide reliable performance even at minimal openings. Manufacturers often employ precision machining techniques to ensure that every aspect of the valve works seamlessly.

Advantages of 3% Gate Valves

3 gate valve

1. Minimal Pressure Drop One of the primary advantages of gate valves, particularly when operated fully open, is the minimal pressure drop across the valve. However, even at a 3% opening, the design allows for controlled flow, minimizing turbulence and energy losses in the system.

2. Durability Constructed from high-quality materials, gate valves are designed to withstand harsh conditions, making them suitable for various industrial applications.

3. Low Maintenance Gate valves generally require less maintenance compared to other valve types because they have fewer moving parts that are exposed to fluid flow.

4. Versatility A 3% gate valve can be used in multiple processes, from water distribution systems to oil and gas applications, due to its ability to offer precise flow control in small increments.

5. Isolation Efficiency This valve is exceptionally effective in providing isolation within a system. By employing a gate valve designed for 3% operation, engineers can ensure that specific sections of a pipeline can be shut off without significant impact on the overall system’s performance.

Applications

3% gate valves find their applications in various fields, including

- Water Treatment Plants For controlling flow rates while minimizing pressure loss. - Oil and Gas Industry In pipelines where precise flow regulation is necessary without compromising system integrity. - Chemical Processing Where control over fluid dynamics is essential for reaction efficiency and safety. - Power Plants In cooling systems for controlling water flow to maintain optimal temperatures.

Conclusion

In summary, the 3% gate valve is an essential component in many fluid control systems. Its ability to regulate flow precisely while maintaining minimal pressure drop offers significant advantages in various industrial applications. As industries continue to evolve, the demand for efficient and reliable valve systems like the 3% gate valve will only grow, highlighting the importance of understanding and implementing advanced valve technologies in fluid management. By investing in quality gate valves, industries can enhance their operational efficiency, reduce downtime, and ensure safety and reliability in their processes.

-

Technical Elucidation of Threaded Ring GaugesNewsJun.23,2025

-

Snap Gauge Critical Tool for Industrial Precision MeasurementNewsJun.23,2025

-

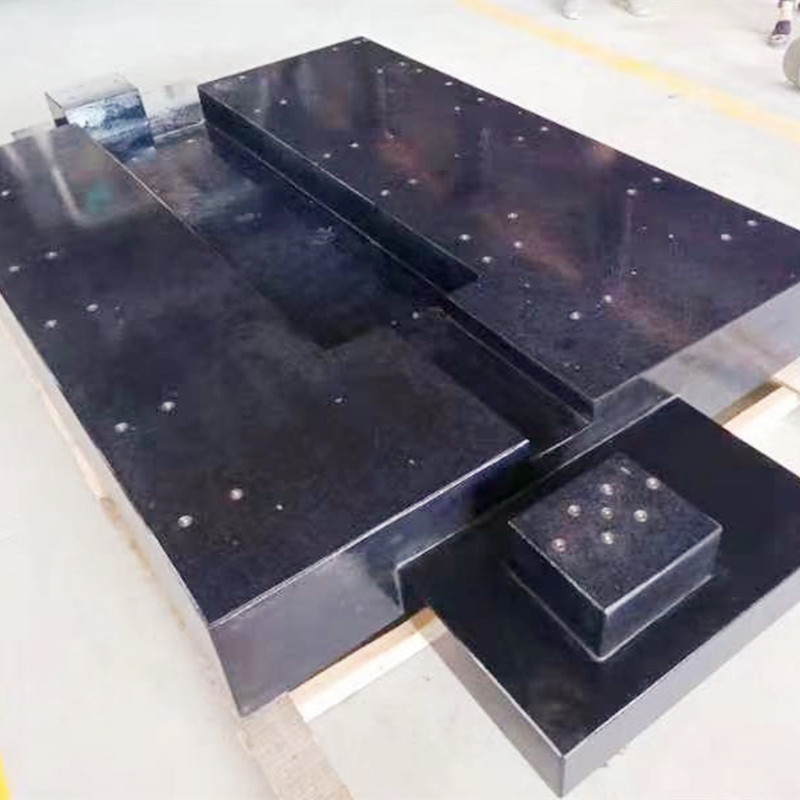

Granite Inspection Tables Precision Tools for Industrial FabricationNewsJun.23,2025

-

Exploring the World of Granite ToolsNewsJun.23,2025

-

Butterfly Valve and Globe Valve Manual An Academic OverviewNewsJun.23,2025

-

Retrofitting Old Systems with Y Type Strainer ValvesNewsJun.20,2025

Related PRODUCTS