nov. . 24, 2024 08:34 Back to list

Choosing the Right Thread Gauge Tool for Precise Measurements and Applications

Understanding Thread Gauge Tools Essential Instruments in Precision Engineering

In the world of precision engineering and manufacturing, the importance of threaded connections cannot be overstated. These connections play a crucial role in various applications, from machinery to automotive parts. To ensure the accuracy and reliability of these threaded components, engineers and machinists rely heavily on thread gauge tools. This article will delve into the significance, types, and proper usage of thread gauge tools, highlighting their indispensable role in ensuring quality and precision in threaded applications.

What is a Thread Gauge Tool?

A thread gauge tool, often referred to as a thread pitch gauge or screw gauge, is a specialized instrument used to measure the pitch and size of screw threads. It consists of a series of metal blades or discs etched with different thread profiles that correspond to various thread standards, including metric and imperial specifications. These tools help in determining the thread size and pitch to ensure compatibility with corresponding threaded hardware.

The Importance of Thread Gauge Tools

Precision is paramount in any engineering process, especially when working with threaded components. An accurate measurement of thread dimensions is essential to prevent issues such as stripping, misalignment, and material fatigue, which can lead to equipment failure and safety hazards. Thread gauge tools provide a quick and efficient means to ascertain thread sizes, making them indispensable in both manufacturing and repair environments. They also play a critical role in quality control by ensuring that products meet specified standards before they are released to the market.

Types of Thread Gauge Tools

There are several types of thread gauge tools, each designed for specific applications

1. Thread Pitch Gauges These tools consist of multiple blades, each representing a different thread pitch. They are primarily used to measure the pitch of external threads, allowing machinists to determine the correct matching nut or threaded component.

2. Plug Gauges Used to check internal threads, plug gauges are cylindrical and fit into threaded holes. They come in Go and No-Go types, with the Go gauge ensuring the thread is within tolerance and the No-Go gauge verifying that the thread does not exceed specified limits.

3. Ring Gauges Similar to plug gauges but designed for external threads, ring gauges are circular and used to measure the outer diameters of threaded components. They provide quick verification of whether a threaded part meets production specifications.

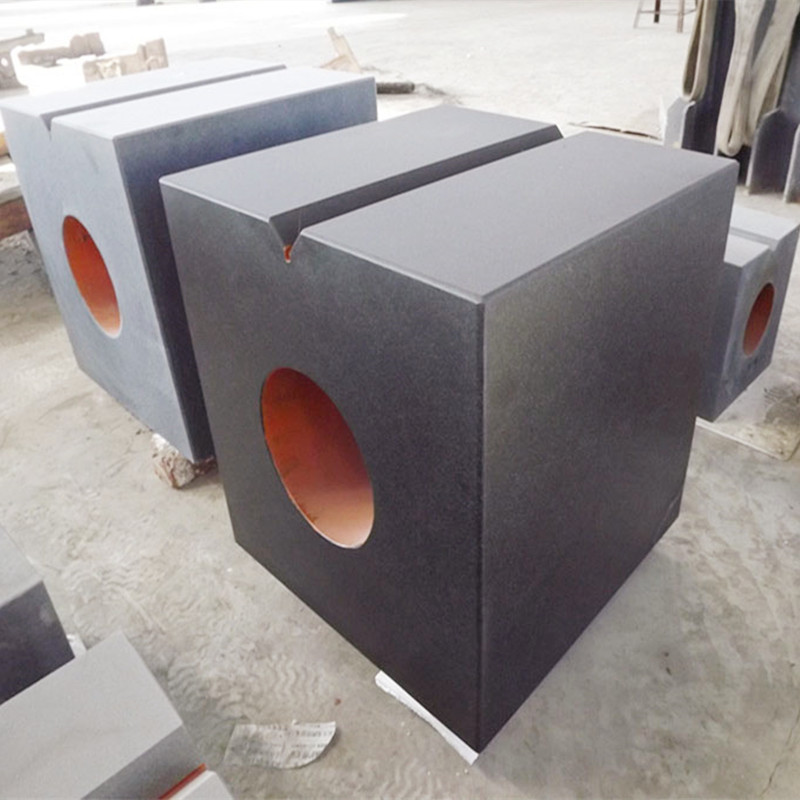

thread gauge tool

4. Tapered Thread Gauges These gauges are used for measuring tapered threads, commonly found in plumbing applications. They assist in ensuring that fittings will create a tight seal in piping systems.

5. Custom Thread Gauges In some cases, manufacturers may require specific thread gauging solutions tailored to unique designs or applications. Custom gauges are manufactured to meet these specialized needs.

How to Properly Use Thread Gauge Tools

Using thread gauge tools correctly is vital for obtaining accurate measurements. Here are some guidelines to follow

1. Clean the Thread Surface Before measuring, ensure that the thread surfaces are clean and free from debris or rust. Contaminants can affect measurement accuracy.

2. Select the Correct Gauge Choose the appropriate gauge based on whether you are measuring internal or external threads. For thread pitch measurements, select a gauge blade that matches the threads in question.

3. Align and Insert For plug gauges, insert the gauge into the threaded hole and ensure it fits snugly. For external threads, position the gauge against the threads and check for a snug fit.

4. Evaluate Fit Determine if the thread meets specifications by checking for proper engagement. For Go and No-Go gauges, the Go gauge should fit easily, while the No-Go should not.

5. Record Measurements Keep accurate records of your measurements for quality control purposes, which can assist in identifying trends and ensuring consistent production standards.

Conclusion

Thread gauge tools are critical in achieving precision and reliability in threaded manufacturing and engineering applications. By utilizing these gauges properly, professionals can ensure that threaded components meet necessary specifications, reducing the risk of failure and enhancing overall quality. In an ever-evolving industry, the role of thread gauge tools remains paramount in maintaining the integrity and safety of products we use every day. Understanding their importance and proper usage will, undoubtedly, contribute to better engineering practices and superior outcomes.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS