oct. . 10, 2024 23:54 Back to list

ring gauge is used for

The Importance of Ring Gauges in Quality Control and Measurement

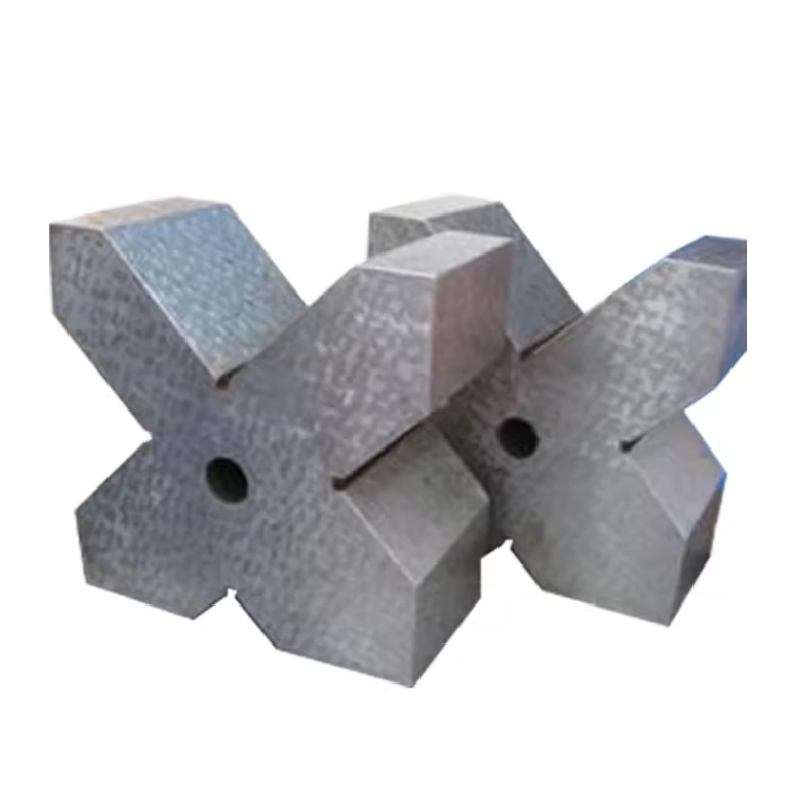

In various industries, precision measurement is critical for ensuring product quality and functionality. One of the essential tools used for this purpose is the ring gauge. A ring gauge is a cylindrical tool designed to measure the external diameter of a workpiece or to check the fit of shafts and other round components. Its use spans across multiple fields, including manufacturing, automotive, aerospace, and many others, where accuracy is paramount.

Understanding Ring Gauges

Ring gauges, also known as ring calipers or ring inserts, come in two main types GO and NOGO gauges. The GO gauge is used to check whether a part falls within the specified tolerance limit—essentially, it verifies if the part is 'good' for use. The NOGO gauge, on the other hand, is designed to indicate whether a part exceeds the upper limit of its intended size. By employing both types, operators can determine if a component meets the design specifications and is suitable for assembly or use.

The construction of ring gauges involves high-quality materials, often hardened steel, to ensure durability and long-term accuracy. They are meticulously manufactured and calibrated to meet strict industry standards, such as ISO and ANSI guidelines. This attention to detail is crucial, as even minor deviations can lead to significant issues in the end product, including failure in operation or premature wear.

Applications of Ring Gauges

The versatility of ring gauges allows them to be used in a wide array of applications. In the automotive industry, they are integral in the production of engine components, ensuring that parts fit together seamlessly and operate effectively. For example, the dimensions of the cylinder shafts, which house pistons, must be precise to ensure optimal performance. Similarly, in the aerospace sector, where safety and reliability are non-negotiable, ring gauges help maintain the stringent quality standards necessary for aircraft and spacecraft components.

ring gauge is used for

In manufacturing environments, ring gauges play a crucial role in quality control processes. By integrating these tools into production lines, manufacturers can conduct real-time checks to catch defects early, reducing waste and ensuring that only parts that meet quality standards move forward in production. This proactive approach not only saves time and resources but also enhances customer satisfaction through improved product reliability.

Benefits of Using Ring Gauges

Investing in ring gauges brings numerous benefits to businesses. First and foremost, they enhance measurement accuracy. By utilizing GO and NOGO gauges, companies can quickly identify non-conforming parts, preventing them from entering the assembly process. This leads to a significant reduction in rework and scrap rates, which directly impacts operational efficiency and cost-effectiveness.

Furthermore, the use of ring gauges fosters a culture of precision within manufacturing plants. When employees regularly check the dimensions of their workpieces, it reinforces the importance of quality control. This practice can lead to a more conscientious workforce that takes pride in producing high-quality products.

Additionally, modern ring gauges can be integrated with digital measurement systems, enabling more advanced data analysis and record-keeping. This integration allows for greater traceability and easier compliance with industry regulations, making it simpler for businesses to demonstrate their commitment to quality to clients and inspectors alike.

Conclusion

In conclusion, ring gauges are indispensable tools in the realm of precision measurement and quality control. Their ability to provide accurate checks on component dimensions ensures that products meet prescribed standards and regulatory requirements. With their extensive applications and significant benefits, investing in quality ring gauges is crucial for any business that prioritizes accuracy and reliability in its manufacturing processes. Embracing such tools not only enhances operational efficiency but also strengthens a company’s reputation for quality, ultimately leading to greater customer satisfaction and loyalty. As industries continue to evolve, the role of ring gauges will remain vital to achieving precision engineering and manufacturing excellence.

-

Retrofitting Old Systems with Y Type Strainer ValvesNewsJun.20,2025

-

Predictive Maintenance Strategies for Industrial Butterfly ValvesNewsJun.20,2025

-

Optimizing Check Valve Types Performance in Harsh EnvironmentsNewsJun.20,2025

-

Material Selection for Ball Check ValvesNewsJun.20,2025

-

Cost-Effective Selection Criteria for Globe Gate Valve SizingNewsJun.20,2025

-

Control Valve Selection Criteria for Water Treatment PlantsNewsJun.20,2025

Related PRODUCTS