nov. . 12, 2024 13:54 Back to list

3 4 flanged gate valve

The Importance and Applications of 3% 204% Flanged Gate Valve

In industrial environments, the control and direction of fluid flow is a critical aspect of operations. Among the myriad of control devices available, the flanged gate valve stands out for its effectiveness and reliability. Specifically, the 3% and 204% flanged gate valves are noteworthy due to their unique specifications and applications in various sectors.

Understanding Flanged Gate Valves

A flanged gate valve is designed primarily for two positions fully open or fully closed. The mechanism of the gate valve operates via a gate that moves perpendicular to the flow of fluid. When the valve is in the open position, the gate is fully retracted, allowing water or other fluids to flow freely with minimal resistance. In contrast, when closed, the gate fits tightly against the seat, preventing any fluid passage.

The “3%” and “204%” references in these types of flanged gate valves typically denote specific configurations or performance metrics relevant to the manufacturing or testing process. Such metrics can be crucial for engineers speculating on pressure drops, connection standards, and flow characteristics.

Key Benefits of 3% 204% Flanged Gate Valves

1. Robust Design The flanged construction allows for easy installation and a stable connection to pipes, ensuring a high level of leak-proof integrity. This is particularly significant in industries where fluid loss could lead to safety hazards or increased costs.

2. Versatility in Applications Due to their robust design and operational efficiency, these valves find applications across various industries, including water treatment, oil and gas, chemical processing, and power generation. Their effectiveness at controlling large volumes of fluids with low friction losses makes them ideal for high-capacity systems.

3. Durability The materials used in the construction of these valves, often including stainless steel or other corrosion-resistant alloys, ensure longevity even under harsh conditions. This durability is crucial in applications involving aggressive chemicals or high temperatures.

3 4 flanged gate valve

4. Ease of Maintenance Flanged gate valves are relatively easy to maintain. With straightforward disassembly procedures, operators can replace or repair internal components without significant downtime. This ease of repair contributes to operational efficiency and cost-effectiveness over the life of the valve.

Application Scenarios

In the water treatment industry, the need for reliable flow control is paramount. The 3% 204% flanged gate valves are often used in the isolation of equipment, allowing maintenance to occur without affecting the overall system.

In the oil and gas sector, these valves manage the flow of crude oil and natural gas, where pressures can vary dramatically. The ability to maintain a tight seal against high-pressure fluids is critical, making these valves a trusted component in pipelines and refineries.

Industrial chemical processes also benefit from the flanged gate valve's versatility. In environments that handle corrosive substances, the choice of materials and the precision of design ensure that the valves maintain integrity and safety throughout their service life.

Conclusion

The 3% 204% flanged gate valve represents a significant component in fluid control systems within various industries. Its design offers robustness, easy installation, and reliability—factors that are paramount in high-capacity applications. As industries continue to evolve and demand greater efficiency and safety, the significance of such valves, along with their ability to adapt to diverse environments, cannot be overstated. By investing in high-quality flanged gate valves, companies can enhance their operations and ensure a secure and efficient flow management system, ultimately leading to significant cost savings and improved operational outcomes.

In conclusion, flanged gate valves, particularly those characterized by distinct metrics like 3% and 204%, are essential in facilitating controlled fluid flow across a range of industrial applications. Their contributions to safety, efficiency, and reliability make them indispensable in modern fluid management solutions.

-

Rising Demand for Corrosion-Resistant Metal Valves in Wholesale MarketsNewsMay.30,2025

-

Revolutionizing Industrial Workholding for Fabrication Table ClampsNewsMay.30,2025

-

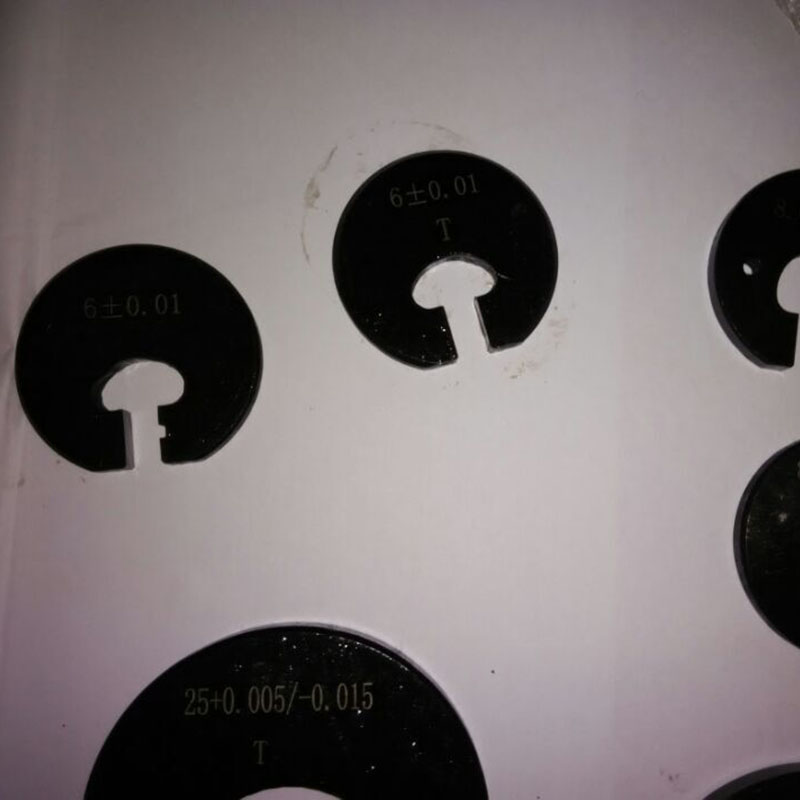

Precision Measurement: Plug Gauges in Industrial Quality ControlNewsMay.30,2025

-

Material Selection and Durability in Heavy-Duty Welding Table WorkbenchesNewsMay.30,2025

-

Durability and Maintenance of Granite Fabrication TablesNewsMay.30,2025

-

Precision in Measurement: Why a Quality Inspection Platform MattersNewsMay.29,2025

Related PRODUCTS