Dez . 20, 2024 05:34 Back to list

ultra magnetic v block

The Ultra Magnetic V Block A Revolutionary Tool for Precision Work

In the realm of precision engineering and machining, tools that enhance accuracy and efficiency are invaluable. Among these tools, the Ultra Magnetic V Block stands out as a revolutionary device that combines innovation with practicality. This specialized equipment has become essential for various applications in metalworking, fabrication, and assembly processes, ensuring that professionals achieve optimal results.

The Design and Functionality of Ultra Magnetic V Blocks

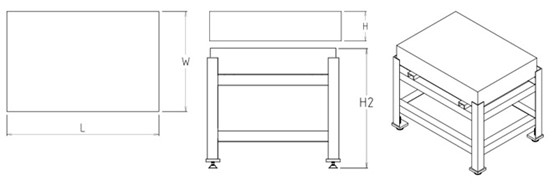

The Ultra Magnetic V Block features a robust and compact design, typically crafted from high-quality materials such as hardened steel. Its hallmark characteristic is the V-shaped groove on its surface, which allows it to securely hold cylindrical objects, such as shafts and pipes, at various angles. What truly sets the Ultra Magnetic V Block apart is its integrated magnetic system, which produces a strong magnetic attraction capable of securely clamping ferromagnetic materials.

This magnetic capability not only provides stability during the machining process but also improves the safety of operations. When working with heavy materials, the Ultra Magnetic V Block minimizes the risk of slips and shifts, ensuring that precision measurements can be consistently maintained. The ease of setup due to the magnetic clamping also reduces downtime, allowing machinists to focus on their work without frequent interruptions.

Versatility in Applications

One of the most appealing aspects of the Ultra Magnetic V Block is its versatility. It can be employed in a wide range of applications, making it a must-have tool in workshops and manufacturing plants. From inspecting and measuring workpieces to performing layout tasks and assembling components, the Ultra Magnetic V Block demonstrates its efficacy in various scenarios.

ultra magnetic v block

In quality control, for instance, the V Block can be used to hold and measure parts during inspection processes. Its magnetic features allow for quick adjustments, ensuring that measurements are taken accurately. Additionally, during machining operations such as grinding or milling, the block keeps workpieces securely in place, allowing for superior cut precision and surface finish.

Benefits Over Traditional Methods

Traditionally, machinists would rely on mechanical clamps or vises to hold workpieces, which could often be cumbersome and time-consuming to set up. The Ultra Magnetic V Block eliminates many of these challenges. Its magnetic clamping mechanism not only speeds up the setup process but also provides more consistent holding power. Unlike conventional clamps that can lose grip over time or with changing conditions, the magnetic hold remains reliable, making it particularly advantageous in high-volume production environments.

Moreover, the Ultra Magnetic V Block can accommodate various shapes and sizes, thanks to its unique design. This flexibility allows manufacturers to streamline their operations, reducing the need for multiple specialized clamping tools. Instead, a single unit can suffice for different tasks, saving both space and costs.

Conclusion

In summary, the Ultra Magnetic V Block signifies a significant advancement in precision tooling. Its innovative design, strong magnetic capabilities, and versatility make it a crucial asset for professionals in various fields. As industries continue to evolve, tools like the Ultra Magnetic V Block will no doubt play a pivotal role in enhancing productivity and accuracy in machining and fabrication processes. By investing in such advanced equipment, businesses can not only improve their workflow but also ensure the highest standards of precision in their outputs. For any professional seeking to elevate their craftsmanship, the Ultra Magnetic V Block is a worthy addition to the toolkit.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS