Nov . 10, 2024 06:55 Back to list

24-inch gate valve specifications and applications for industrial use and piping systems

The Importance of 24-Inch Gate Valves in Industrial Applications

Gate valves are essential components in various industrial systems, particularly in the management of fluid flow. Among the several sizes available, the 24-inch gate valve stands out for its robust functionality and versatility in dealing with sizable pipelines across diverse sectors. Understanding the importance of this valve type can aid in making informed decisions regarding installation, maintenance, and operational efficiency.

What is a Gate Valve?

Before delving into the specifics of a 24-inch gate valve, it is crucial to understand what a gate valve is. A gate valve is a type of valve that opens or closes by lifting a gate out of the path of the fluid. They are primarily used to start or stop flow, rather than to regulate it. This type of valve is favored in large pipelines due to its minimal pressure drop and low flow resistance when fully opened.

Design and Features of 24-Inch Gate Valves

The 24-inch gate valve is designed to handle considerable volumes of fluid, making it suitable for applications in water treatment plants, chemical processing, oil and gas, and power generation. Generally made from durable materials like cast iron, stainless steel, or carbon steel, these valves are engineered to withstand high pressures and corrosive environments.

One of the key features of a 24-inch gate valve is its wedge design which facilitates a tight seal when closed. The wedge can be either parallel or inclined, with each type offering different sealing capabilities and benefits depending on the application. The parallel wedge gate valve provides better sealing but might have higher resistance during opening and closing, while the inclined wedge allows for easier operation at the cost of slightly less effective sealing.

Applications of 24-Inch Gate Valves

In industrial settings, 24-inch gate valves are commonly employed in various applications

24 inch gate valve

1. Water Supply and Distribution Systems In municipal water systems, these valves are crucial for controlling the flow and maintenance of water pipelines. 2. Wastewater Management Gate valves are used in sewage and wastewater treatment plants to manage the flow of effluent and prevent backflow.

3. Oil and Gas Pipelines These valves play a vital role in the oil and gas sector, providing reliable shut-off capabilities to protect equipment and ensure safety during transporting fluids.

4. Fire Protection Systems In fire protection, large diameter gate valves are installed in sprinkler systems to provide quick and efficient response in emergencies.

Advantages of 24-Inch Gate Valves

The advantages of using 24-inch gate valves are numerous. Firstly, their robust design allows them to operate effectively in high-pressure environments. Secondly, when fully opened, they present a straight path for fluid flow, resulting in minimal turbulence and pressure loss. Additionally, these valves require relatively little maintenance if installed correctly, contributing to reduced downtime and operational costs.

Maintenance Considerations

While gate valves are generally durable, regular maintenance is still essential to ensure their longevity and performance. Operators should inspect them periodically for signs of wear, corrosion, or leakage. Greasing moving parts and ensuring that seals are intact can prevent operational failures. Furthermore, it is vital to operate the valve fully open or closed to avoid damaging the gate mechanism.

Conclusion

In conclusion, the 24-inch gate valve is an indispensable component in many industrial processes that involve the transport and management of fluids. Their robust construction, reliability, and efficiency make them a preferred choice in various applications, from water treatment to oil and gas pipelines. Understanding their design, applications, and maintenance needs will enable industries to leverage their full potential, ensuring safe and efficient operations. As industries continue to evolve, the role of such valves will remain critical in meeting operational demands and achieving sustainability goals.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

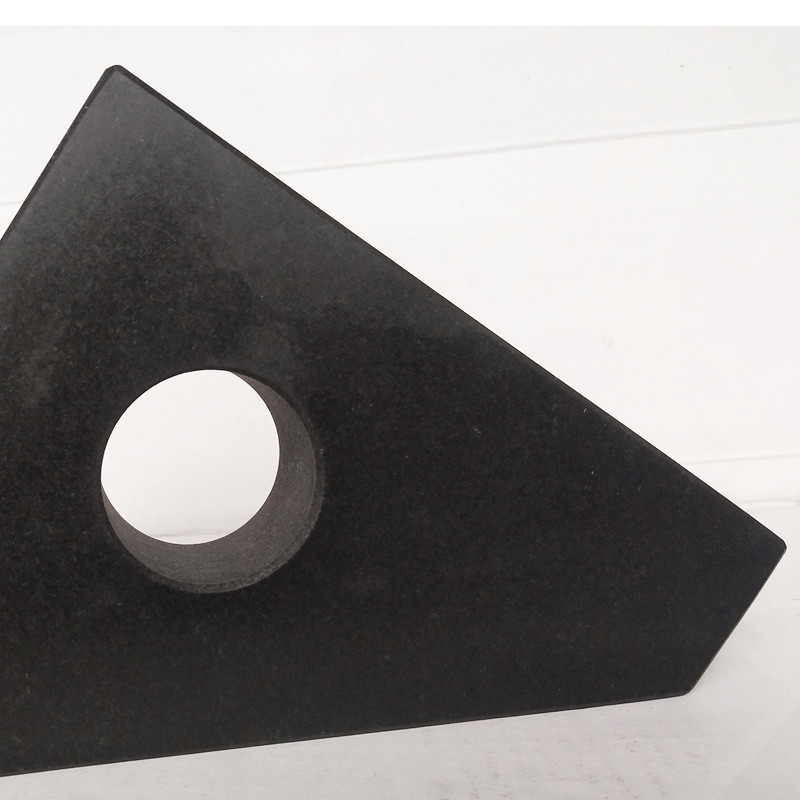

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS