lip . 31, 2025 17:02 Powrót do listy

Cast Iron Lapping Plates for Precision Engineering Solutions

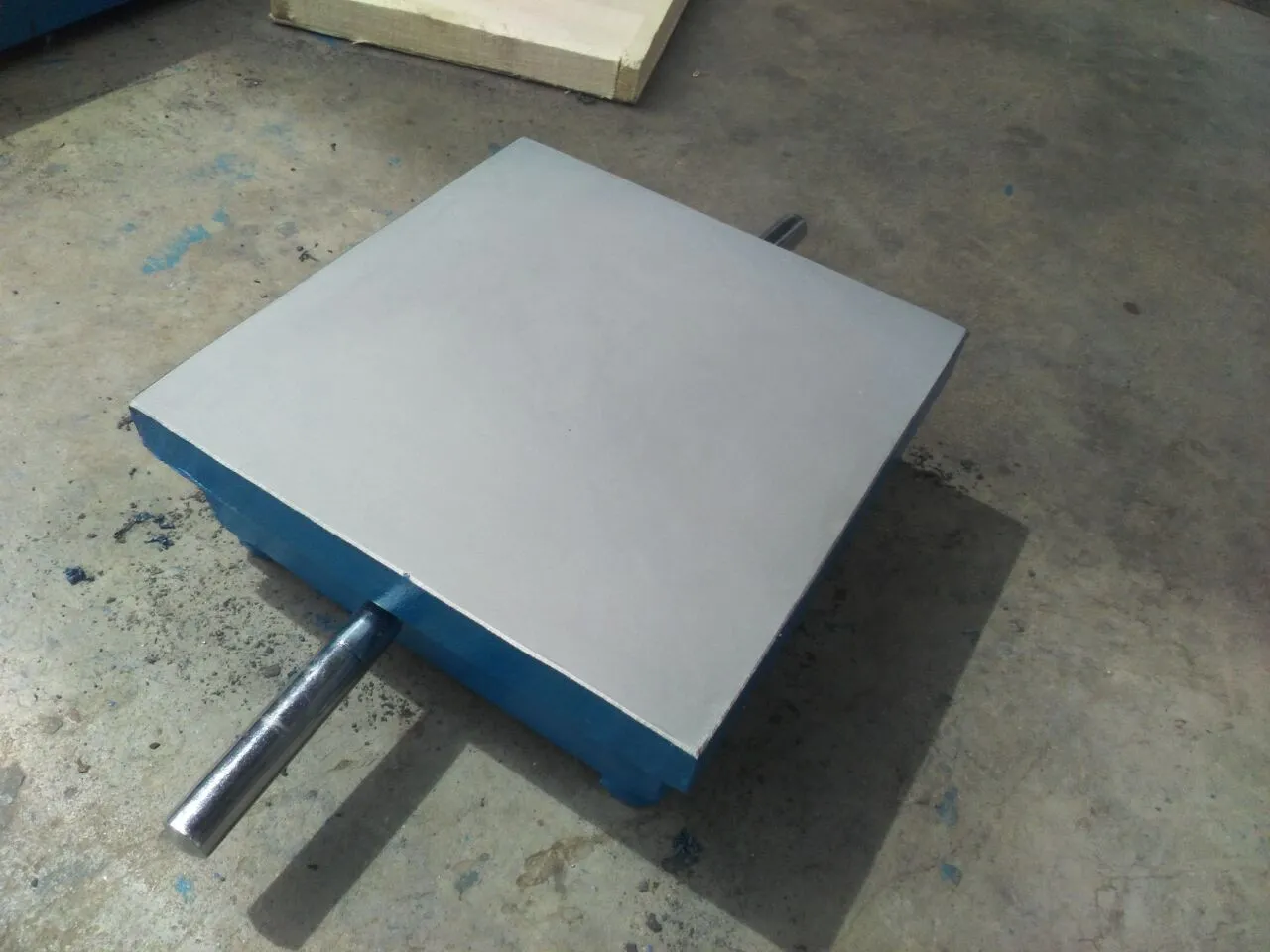

When superior flatness and durability matter most, Cast Iron Lapping Plates from Storaen (Cangzhou) International Trading Co. deliver unmatched performance. Our precision-engineered Iron Surface Plates and Cast Iron Base Plates provide the stable foundation needed for critical measurement and machining applications across industries. Trusted by manufacturers worldwide, these solutions combine traditional craftsmanship with modern quality control.

Cast Iron Lapping Plate Superior Flatness and Durability

When it comes to achieving ultra-flat surfaces for precision machining and tooling, the Cast Iron Lapping Plate stands out as an essential tool. These plates are meticulously crafted from high-grade cast iron, ensuring long-term stability and resistance to wear. The Cast Iron Lapping Plate undergoes specialized heat treatment to eliminate internal stresses, guaranteeing consistent performance under rigorous industrial conditions.

At Storaen (Cangzhou) International Trading Co., we specialize in supplying top-tier Cast Iron Lapping Plates designed for grinding, lapping, and finishing applications. Their ribbed structure enhances rigidity, while the resin sand casting process ensures a defect-free surface. Whether used in metrology labs or manufacturing workshops, these plates deliver unmatched accuracy for fine-tuning precision components.

Cast Iron Base Plates The Foundation of Precision Workholding

A Cast Iron Base Plate serves as the backbone for many industrial setups, providing a stable and vibration-resistant platform for machining, assembly, and inspection. Made from high-quality materials like HT200-300 or QT, these plates are built to withstand heavy loads while maintaining dimensional integrity.

Storaen (Cangzhou) International Trading Co. offers customizable Cast Iron Base Plates in various sizes, from compact workbenches to large industrial layouts. Their ribbed construction ensures optimal weight distribution, while the hardened working surface (HB160-240) resists wear over time. Whether used in automotive, aerospace, or toolmaking, these plates ensure reliable performance for years.

|

Parameter |

Detale |

|

Place of Origin |

Hebei, China |

|

Warranty |

1 year |

|

Customized support |

OEM, ODM, OBM |

|

Brand Name |

Storan |

|

Model Number |

2011 |

|

Materiał |

Cast iron (HT200-300, QT, or steel) |

|

Rozmiar |

200x200mm – 4000x8000mm (customizable) |

|

Hardness of Working Surface |

HB160-240 |

|

Foundry Process |

Resin sand casting |

|

Structure |

Rib (bone) structure with enough wall thickness |

|

Obraz |

Primer and face paint |

|

Stopień precyzji |

0-3 |

|

Working Temperature |

(20±5) ℃ |

|

Opakowanie |

Plywood box |

Iron Surface Plate The Gold Standard for Metrology

An Iron Surface Plate is indispensable in precision measurement, providing a reference plane for inspection, marking, and gauging operations. Cast Iron Surface Plates are made from high-grade cast iron (C.I) and undergo stress-relieving heat treatment to ensure long-term flatness.

At Storaen (Cangzhou) International Trading Co., our Iron Surface Plates are available in multiple precision grades (0-3), making them ideal for quality control labs and production floors. The ribbed design enhances stability, while the resin sand casting process minimizes internal defects. Whether used for layout work or verifying part dimensions, these plates ensure accuracy in every application.

Cast Iron Base Plates Why They Excel for Precision Applications

The superiority of Cast Iron Lapping Plates, Cast Iron Base Plates, and Iron Surface Plates lies in their material properties. Cast iron offers excellent vibration damping, thermal stability, and wear resistance—qualities critical for high-precision work.

Storaen (Cangzhou) International Trading Co. ensures every plate meets stringent quality standards, from material selection to final inspection. Whether you need a Cast Iron Lapping Plate for fine finishing or an Iron Surface Plate for metrology, our solutions are built for industrial durability and precision.

FAQS about Cast Iron Surface Plates

How does a cast iron lapping plate improve surface finishing?

The Cast Iron Lapping Plate excels in surface finishing due to its exceptional flatness and grain structure. When used with abrasives, it creates a perfectly uniform surface by removing microscopic imperfections. The plate's vibration-dampening properties prevent chatter marks, resulting in smoother finishes than alternative materials can achieve.

What advantages do cast iron base plates offer over steel alternatives?

Cast Iron Base Plates provide superior vibration absorption and thermal stability compared to steel plates. Their crystalline structure naturally dampens harmonics during machining operations, reducing tool wear and improving surface finishes. Additionally, cast iron maintains dimensional stability across temperature fluctuations common in industrial environments.

Why are iron surface plates preferred for precision measurement?

Iron Surface Plates remain the preferred choice for metrology because their porous structure retains lubricants better than non-porous materials. This characteristic reduces friction during measurement while maintaining the plate's flatness over decades of use. The material's wear resistance ensures consistent accuracy for layout work and inspection tasks.

Can cast iron lapping plates be resurfaced when worn?

Yes, Cast Iron Lapping Plates can be resurfaced multiple times throughout their service life. Professional refinishing involves precision grinding followed by hand scraping to restore the original flatness. This process extends the plate's usability far beyond other materials, making it a cost-effective long-term investment for precision workshops.

How do environmental factors affect iron surface plate accuracy?

Iron Surface Plates require stable environmental conditions as temperature variations can cause temporary dimensional changes. Maintaining the recommended (20±5)℃ working environment ensures optimal performance. Proper storage on three-point supports prevents warping, while regular calibration maintains the plate's certified accuracy for quality control applications.

-

Precision Manufacturing with Advanced Spline Gauge DesignAktualnościJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsAktualnościJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsAktualnościJul.31,2025

-

High-Performance Gate Valve WholesaleAktualnościJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementAktualnościJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersAktualnościJul.31,2025

Produkty powiązane