ਦਸੰ. . 24, 2024 08:39 Back to list

Various Types of Water Check Valves and Their Applications

Types of Check Valves for Water

Check valves play a crucial role in fluid control systems, particularly in water applications. These valves are designed to allow fluid flow in one direction while preventing backflow, which can lead to system inefficiencies and potential damage. With various designs tailored for specific applications, choosing the right type of check valve is essential for ensuring optimal performance. This article explores the most common types of check valves used for water systems.

1. Swing Check Valves

Swing check valves are characterized by a disc that swings on a hinge to allow flow in one direction. When the flow reverses, the disc closes against the seat, preventing backflow. These valves are popular for their simplicity and effectiveness in low- to medium-pressure systems. They work well in larger pipe diameters where the flow velocity is significant, as the weight of the disc helps to seal the valve tightly. However, they may not perform well in applications with pulsating flow.

2. Lift Check Valves

Lift check valves utilize a vertically moving disc to control flow. When fluid flows in the forward direction, the disc rises, allowing water to pass through. When backflow occurs, the disc falls back onto the seat, stopping the reverse flow. These valves are more suitable for applications with higher pressure and are often used in smaller pipe sizes. Lift check valves are known for their ability to seal effectively and can handle higher flow rates than swing check valves.

types of check valves for water

Ball check valves incorporate a spherical ball that moves to block or allow flow. When fluid flows in the correct direction, the ball is lifted off its seat, allowing water to flow through. If the flow direction reverses, gravity or pressurized fluid pushes the ball back onto the seat, blocking backflow. Ball check valves are especially beneficial in applications where a tight seal is necessary, making them ideal for preventing leakage. They are compact, making them suitable for installations with limited space.

4. Diaphragm Check Valves

Diaphragm check valves use a flexible diaphragm that moves up and down to control flow. When fluid moves in the forward direction, the diaphragm lifts, allowing passage, and when flow reverses, the diaphragm seals against the valve body. These valves are particularly effective in handling sludge, slurries, and other fluids with solid particles. Their design reduces wear and tear on internal components, increasing longevity, making them an excellent choice for wastewater treatment facilities and industrial applications.

5. Tilting Disc Check Valves

Tilting disc check valves feature a disc that tilts on a pivot rather than swinging freely. This unique design allows for a more efficient sealing mechanism, as the disc aligns with the seat regardless of flow velocity. These valves are well-suited for high-flow applications and can handle a range of pressures. Their ability to minimize turbulence during operation helps improve overall system efficiency, making them a popular choice in large municipal water systems and industrial pipelines.

Conclusion

Selecting the appropriate check valve for water applications involves understanding the specific requirements of your system, including flow rate, pressure, and potential backflow conditions. The various types of check valves, including swing, lift, ball, diaphragm, and tilting disc, each come with unique advantages and are designed to meet different application needs. By carefully considering these factors, engineers and system designers can ensure reliable water flow management, enhance system efficiency, and prolong the life of their hydraulic systems. Whether for residential, commercial, or industrial applications, the right check valve is essential for maintaining optimal performance in water systems.

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

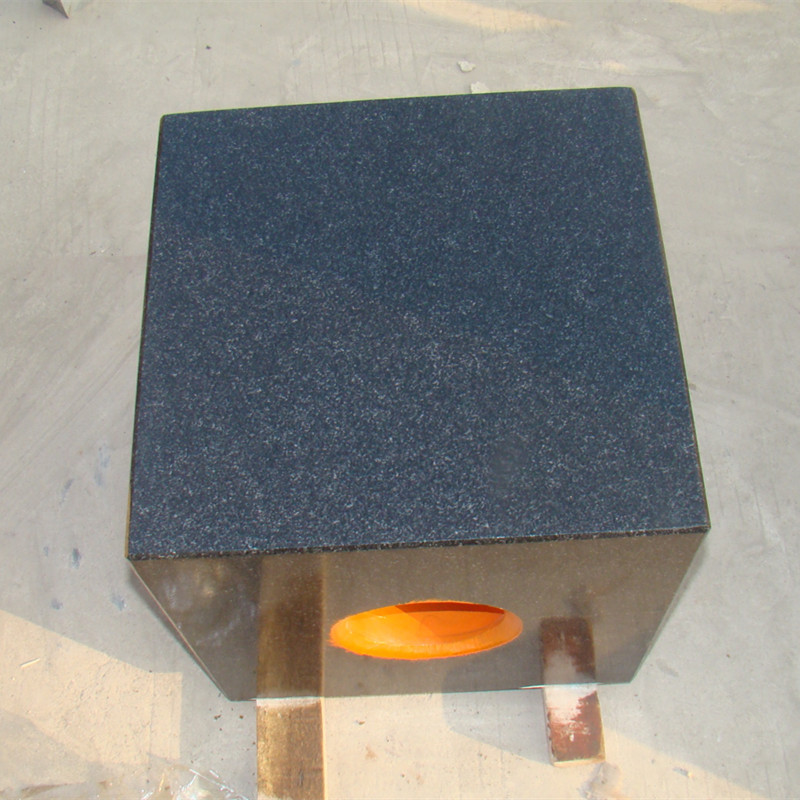

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS