ਦਸੰ. . 24, 2024 06:54 Back to list

reading a dial bore gauge

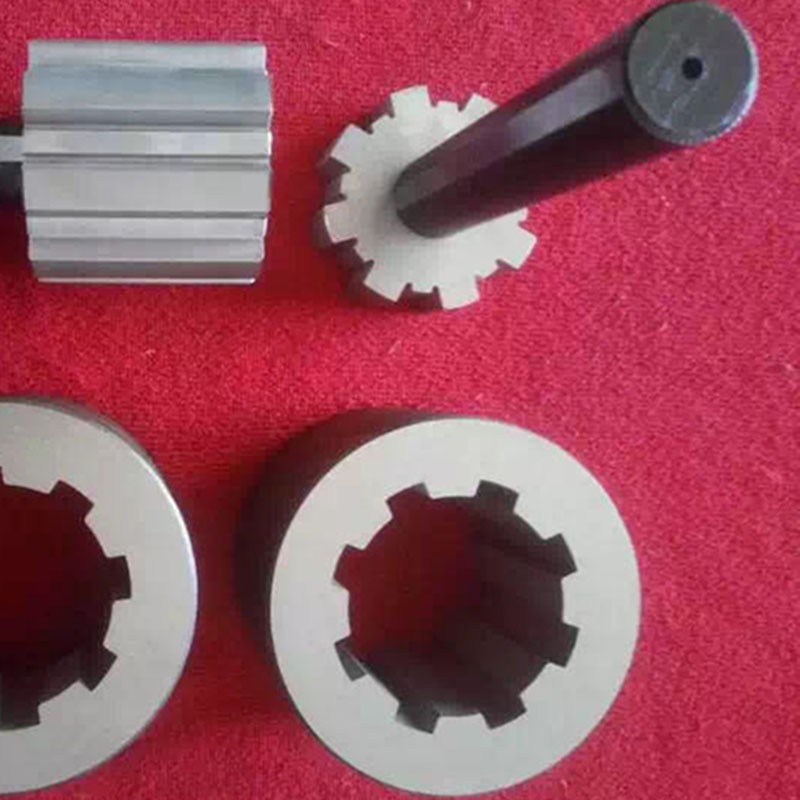

Understanding and Using a Dial Bore Gauge

Measuring the internal diameter of a bore accurately is critical in various mechanical and engineering applications. Whether you're working on engine components, hydraulic cylinders, or machined parts, possessing the right tools and knowledge to take precise measurements can significantly impact the performance and longevity of the assembly. One of the most reliable tools for this purpose is the dial bore gauge.

What is a Dial Bore Gauge?

A dial bore gauge is a specialized measuring instrument designed to measure the internal diameter of a bore or cylinder with remarkable accuracy. It typically includes a dial indicator mounted on a fixture that allows the user to gauge the diameter at various points within the bore. The device operates on the principle of comparative measurement, meaning that it measures the difference in depth between the bore and the calibrated zero point of the gauge, allowing for extremely precise readings.

Components of a Dial Bore Gauge

The key components of a dial bore gauge include

1. Dial Indicator This is the main measurement display part that shows the deviation from zero in either inches or millimeters. The indicator's sensitivity is crucial for accurate readings.

2. Measuring Rods These rods can be adjusted to extend to the desired length, allowing measurement from the bottom of the bore to the surface.

3. Contact Points These are small, rounded tips that come in contact with the bore walls. They are often made of hardened steel to resist wear and provide consistent readings.

4. Head Assembly This is the part of the gauge that houses the dial indicator and allows for adjustments in alignment and measurement depth.

How to Use a Dial Bore Gauge

reading a dial bore gauge

Using a dial bore gauge requires a few steps to ensure accuracy and reliability. Here’s a simple guide on how to operate it effectively

1. Calibration Before taking measurements, calibrate the dial bore gauge. This involves setting it to zero at a known reference point. Make sure to adjust the dial indicator so that it reads zero when the gauge is set within a standard tolerance range.

2. Inserting the Gauge Carefully insert the gauge into the bore you intend to measure. Rotate the gauge as you insert it to ensure it's aligned with the bore's axis.

3. Adjusting to Diameter Once inside the bore, expand the gauge until the contact points touch the bore wall. This is done by turning the adjuster knob on the side of the gauge. When the contact points touch, you may need to rotate the gauge slightly to find the most accurate reading.

4. Taking the Reading Observe the dial indicator reading. This shows the deviation from the set zero and can indicate whether the bore is within the specified tolerances or if it is out of round, tapered, or worn.

5. Reposition as Necessary Move the gauge to various points along the bore to check for consistency. This is essential for detecting any irregularities in the bore shape.

Advantages of Using a Dial Bore Gauge

The dial bore gauge offers several advantages over other measuring tools. Its high accuracy makes it suitable for critical applications where even minor deviations can result in failures. Furthermore, it allows for quick comparisons during machined component inspections, facilitating timely adjustments and repairs. Another advantage is its ability to measure at various depths and points within the bore, providing a comprehensive view of the bore's condition.

Conclusion

In conclusion, the dial bore gauge is an indispensable tool in the toolkit of engineers, machinists, and hobbyists alike. Understanding how to use it effectively not only ensures the precision of measurements but also enhances the quality of the work being performed. Whether you are measuring for quality control, assessing wear in an engine component, or calibrating machined parts, mastering the use of a dial bore gauge can lead to better results and improved efficiency. Investing time in learning this tool will ultimately pay off in the long run, making your mechanical projects more sound and reliable.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS