ਅਗਃ . 02, 2025 01:20 Back to list

Precision Surface Plates | Granite Metrology Grade | Flatness Guaranteed

1. Market Overview & Industry Trends

Surface plates are foundational elements in precision metrology, machining calibration, and industrial dimension inspection. As global manufacturing quality standards rise, the market demand for high-precision iron surface plate and cast surface plate products has surged significantly. According to 2023 Mordor Intelligence Report, the global surface plate market is expected to reach $650 million by 2027, expanding at a CAGR of 7.8%.

- Material evolution: From traditional gray iron to advanced alloyed cast irons & specialty steels.

- Precision grade: Market shifting toward higher grade (Grade 1, 0, and 00) plates to serve electronics, aerospace, and automotives.

- Customization: Modular, large-format and corrosion-resistant plates becoming more prevalent, especially in metrology labs and heavy machinery industries.

2. Technical Comparison Table: Surface Plate Types

| Product Type | Material | Flatness Grade | Standard Size Range (mm) | Corrosion Resistance | Typical Industry | Expected Service Life |

|---|---|---|---|---|---|---|

| Cast Iron Surface Plate | HT200, HT250, Meehanite | 00, 0, 1, 2 (as per DIN 876 / GB 4986) | 300x300 ~ 4000x8000 | ★★☆☆☆ | Machining, Tool Room, Assembly | 15-25 years |

| Granite Surface Plate | Jinan Black, Black Galaxy | 00, 0, 1+ | 300x300 ~ 6000x6000 | ★★★★☆ | Metrology Lab, Optical, Electronics | 30-50 years |

| Steel Surface Plate | Tool Steel, Hardened Steel | 1, 2 | 200x200 ~ 2500x4000 | ★★★☆☆ | Heavy Machinery, Shipbuilding | 12-20 years |

| Composite Surface Plate | Alloy Matrix + Polymer | 1, 2 | Only customized | ★★★★☆ | Specialty Application | 8-18 years |

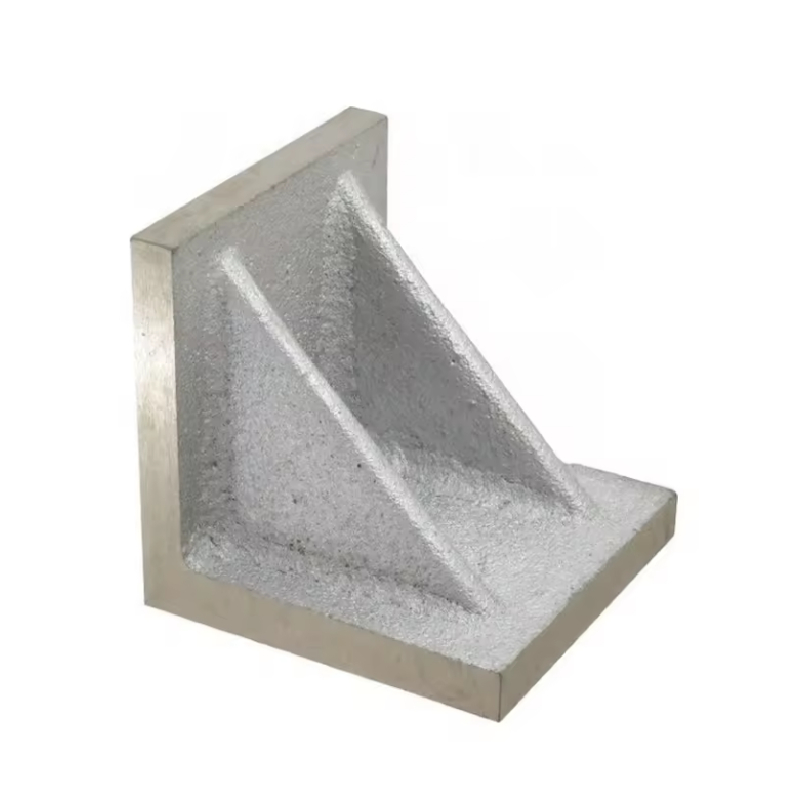

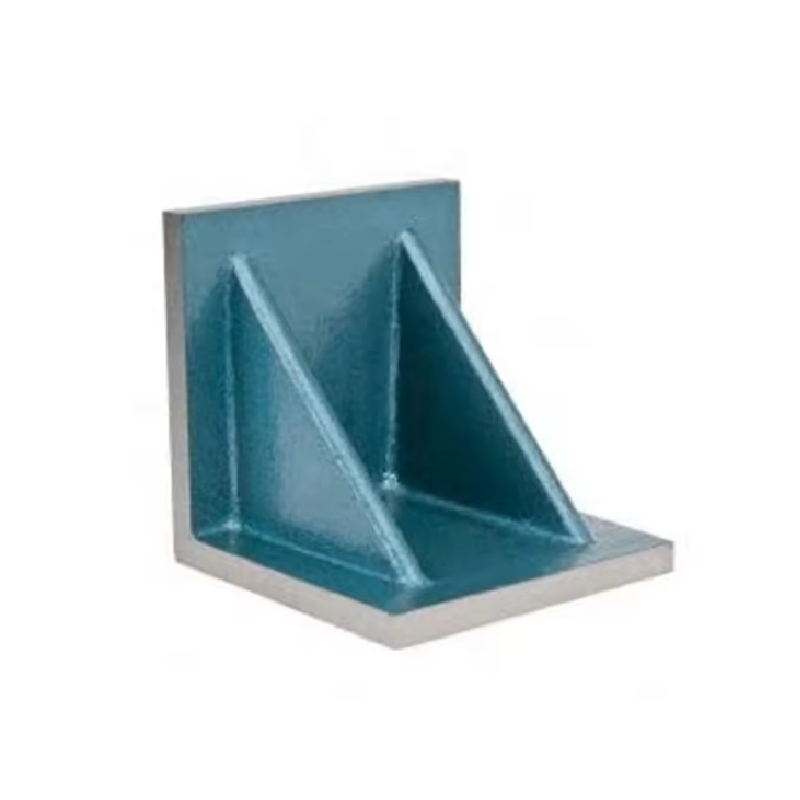

3. Product Spotlight: Cast Iron Angle Plates

- Designed for: Machine tool support, perpendicularity checks, vertical squareness, fixture base.

- Core material: High-grade HT250 cast iron, optimized for rigidity and damping.

- Manufacturing Standard: ISO 2768-1 / DIN 876 on flatness and parallelism.

- Surface Finish: 16~24 μm (Ra), hand scraped for Grade 1 and above.

- Typical Hardness: HB 180~240 (Brinell Hardness)

- Working Surface: Precision ground or scraped as required.

- Corrosion protection: Surface impregnation + painting; edge sealing.

Main Technical Specifications

| Parameter | Value Range |

|---|---|

| Dimension (mm) | 160x100x125 to 2000x1000x1200 |

| Squareness Tolerance | 0.005mm/100mm (Grade 1) |

| Parallelism | 0.006mm/100mm |

| Flatness | 0.010mm/100mm (DIN 876) |

| Net Weight | 10kg - 3200kg |

| Surface Protection | Rust-proof oil + semi-gloss paint |

4. Manufacturing Process: Surface Plate (Cast Iron) Flow Detail

HT250 premium pig iron

High compaction molding for uniform density

Pour molten iron, slow-cool, relieve stress @700°C

Remove surplus, machine datum

Surface to near-final dimension, Ra 24μm

Peak flatness & contact ratio up to 25-40%

Flatness, squareness check (ISO/DIN reference)

Coating, edge protection, wood crating

5. Product Comparison & Price Reference

Cast Iron Surface Plate Price Analysis (2024, Ex-Works, $USD)

| Model (mm) | Grade 1 | Grade 2 | Granite 1 (for ref.) |

|---|---|---|---|

| 400x400x70 | 129 | 110 | 178 |

| 1000x750x180 | 423 | 355 | 526 |

| 1600x1000x220 | 989 | 818 | 1140 |

| 3000x1250x300 | 2680 | 2205 | 2987 |

Product Feature Comparison Chart

Price Distribution – 2024 Market, Cast Iron Angle Plates vs. Granite

6. Customization, Delivery & After-Sales

-

Custom Options:

- Uniquely sized plates (up to 8000x4000mm), T-slotting, lifting hole, grid lines, bolt fixing grooves.

- Abrasion-resistant overlays or induction hardening for high-durability use.

- Optional stainless steel threaded bushings for enhanced utility.

- Delivery Cycle: For standard stock, 7-10 days. For custom plates (extra-large or special flatness), 21-45 days including QA.

- Warranty: 24~36 months after delivery; lifelong technical support. Flatness guarantee with test report.

- After-Sales Service: Free quick calibration, replacement for proven flatness errors, site start-up guidance overseas.

7. Application Scenarios & Case Studies

| Industry | Surface Plate Application | Why (technical reason) | Customer Feedback |

|---|---|---|---|

| Petrochemical | Pump set up, flange inspection, pipe assembly | Resistant to alkali, supports calibration in corrosive environments | “Cast plate offered flatness |

| Metallurgical | Roll/gear housing alignment, heavy fixture mounting | High rigidity, resists deflection under heavy load | “Installation time reduced by 18% vs. granite. Less maintenance.” |

| CNC Machining Shop | Machine bench, tool setup, CMM base support | Compatible with magnetic bases, easier minor scratch repair | “Lowered cost by 27%, achieved repeatable ±3μm accuracy.” |

| Water & Sewage Plants | Valve body inspection, repair section flatness checks | Semi-hardened surface (HB240), tolerates impact, easy cleaning | “Edge wear negligible after 4 years, routine calibration only.” |

Featured Case: Germany Automotive Toolroom

A leading German OEM upgraded to cast iron surface plates in 2022, switching from aged granite plates. After a year, quality audits recorded 26.8% improvement in calibration speed and zero major surface defects reported, attributed to the anti-abrasive finish and precision scraping according to DIN 876 Grade 0 standard.

8. Manufacturer Comparison

| Manufacturer | Country | Standard Supported | OEM/ODM | Main Advantage | Reference Clients |

|---|---|---|---|---|---|

| STR Machinery | China | ISO, DIN, ASME | Yes | Quick custom, low cost, high flatness | Bosch, NASS, Hyundai |

| Mahr GmbH | Germany | DIN, EN | No | Lab grade, ultra-high accuracy | Zeiss, Siemens |

| Starrett | USA | ANSI, ISO | Limited | Durability, strong support | NASA, Boeing |

| Black Granite Inc | India | ISO | Yes | Metric/imperial, affordable price | GE, Tata |

9. FAQ: Surface Plate & Cast Iron Angle Plates

10. Why Choose Certified Surface Plate Manufacturers?

- Long Industry Experience: 20+ years of technical expertise in surface accuracy solutions.

- ISO 9001/ISO 17025 Accreditation: Guarantees traceable QA/QC processes from raw casting to calibration certificate.

- Authoritative Standards: All plates conform to global standards like DIN 876, ISO 8512, ANSI B89.3.7M.

- Global Service: Export coverage to over 48 countries, local reference sites available on request.

- Innovation Leader: Customization, non-standard structures, corrosion-resistant and lightweight options.

11. Summary & References

Whether you’re sourcing a surface plate for laboratory-grade metrology, heavy machine tool setups, or specialized assembly, choosing the right plate type—cast iron, granite, or steel—defines your measurement reliability and operational longevity. Emphasizing manufacturer credibility, compliance with ISO/DIN/ANSI standards, and investing in technical after-sales guarantees optimal ROI and risk mitigation.

- [1] Mordor Intelligence: Surface Plate Market Report 2023

- [2] ZEISS Metrology Forum: Surface Plate Calibration

- [3] ResearchGate: Surface Plate Inspection & Standardization

- [4] Wikipedia: Surface Plate

- [5] NIST: Handbook - Checking the Flatness of a Surface Plate (PDF)

This is the last article

-

Precision Manufacturing with Advanced Spline Gauge DesignNewsJul.31,2025

-

Industrial-Grade Calibrated Pin Gauges for Exact MeasurementsNewsJul.31,2025

-

Industrial Filtration Systems Depend on Quality Filter DN50 SolutionsNewsJul.31,2025

-

High-Performance Gate Valve WholesaleNewsJul.31,2025

-

Granite Surface Plate The Ultimate Solution for Precision MeasurementNewsJul.31,2025

-

Granite Industrial Tools The Ultimate Guide for Bulk BuyersNewsJul.31,2025

Related PRODUCTS