ਦਸੰ. . 24, 2024 13:06 Back to list

Understanding Morse Taper Gauges for Precision Measurement in Tooling Applications

Understanding Morse Taper Gauges A Comprehensive Overview

Morse taper gauges are essential tools in the field of machining and engineering, primarily used for ensuring the accuracy and compatibility of Morse taper connections in various applications. Understanding the Morse taper system and the role of these gauges can greatly enhance the efficiency and effectiveness of machining operations.

What is a Morse Taper?

A Morse taper is a standardized system of tapering used to join two components, typically a tool and a machine spindle. Developed by Stephen A. Morse in the 19th century, this system allows for quick attachment and detachment of tools without the need for threading or additional fasteners. The design features a cone-like shape that provides a secure fit, enhancing stability during operation. Morse tapers are numbered from 0 to 7, with the size corresponding to the diameter of the taper and the specific angle of the taper, which is typically around 1.5 degrees.

The Importance of Gauges

Morse taper gauges are tools used to measure and verify the precise dimensions of Morse taper shanks and sockets. This ensures that tools fit securely into the appropriate machine spindles, maintaining accuracy and safety during machining operations. Without accurate gauging, there could be issues such as tool slippage, vibration, or even catastrophic tool failure, which can lead to costly downtime and potential safety hazards.

The primary purpose of a Morse taper gauge is to check the accuracy of the taper angle and diameter. These gauges are typically made from high-strength materials, offering durability and resistance to wear. They come in various shapes, such as plugs and sockets, designed to correspond to specific Morse taper sizes.

morse taper gauge

How to Use Morse Taper Gauges

Using a Morse taper gauge is a straightforward process, but it requires careful attention to detail. To check a taper shank, one would typically insert the gauge into the taper. A proper fit indicates that the shank is within tolerable limits; if the gauge does not fit correctly, it may suggest that the taper is worn, damaged, or incorrectly manufactured.

In addition to measuring the diameter and angle, the gauge can also be used to inspect for defects. Any irregularities such as chips, bends, or excessive wear can compromise the integrity of the taper connection. Regular gauging is recommended to maintain optimal performance and prolong the lifespan of tooling and machines.

Applications of Morse Taper Gauges

Morse taper gauges are widely used across different industries, including manufacturing, automotive, and aerospace. They play a vital role in ensuring that machinery operates efficiently and safely. For instance, in a CNC machining environment, where precision is paramount, the proper fit of tooling directly impacts production quality. Ensuring that each tool is accurately gauged before use can greatly reduce the likelihood of defects and improve overall productivity.

Conclusion

In summary, Morse taper gauges are indispensable tools in machining and engineering that ensure the proper fit of Morse taper connections. By providing a reliable means to measure and validate taper dimensions, these gauges minimize the risks associated with tool slippage and misalignment, leading to safer and more efficient operations. For anyone involved in machining, understanding and utilizing Morse taper gauges can significantly enhance both the quality of work produced and the longevity of tools and machinery.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

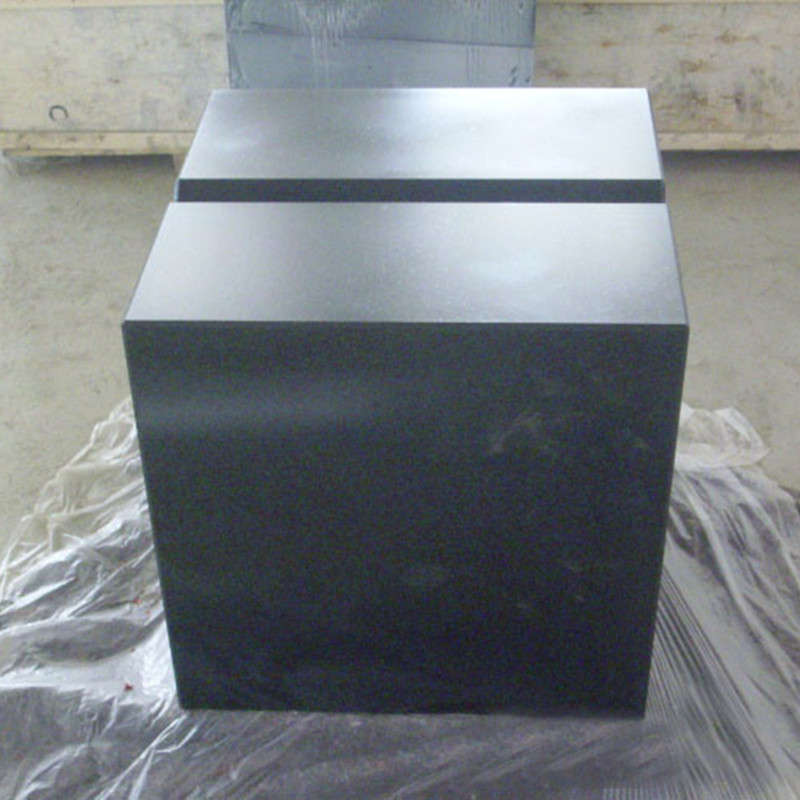

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS