ਸਤੰ. . 26, 2024 02:55 Back to list

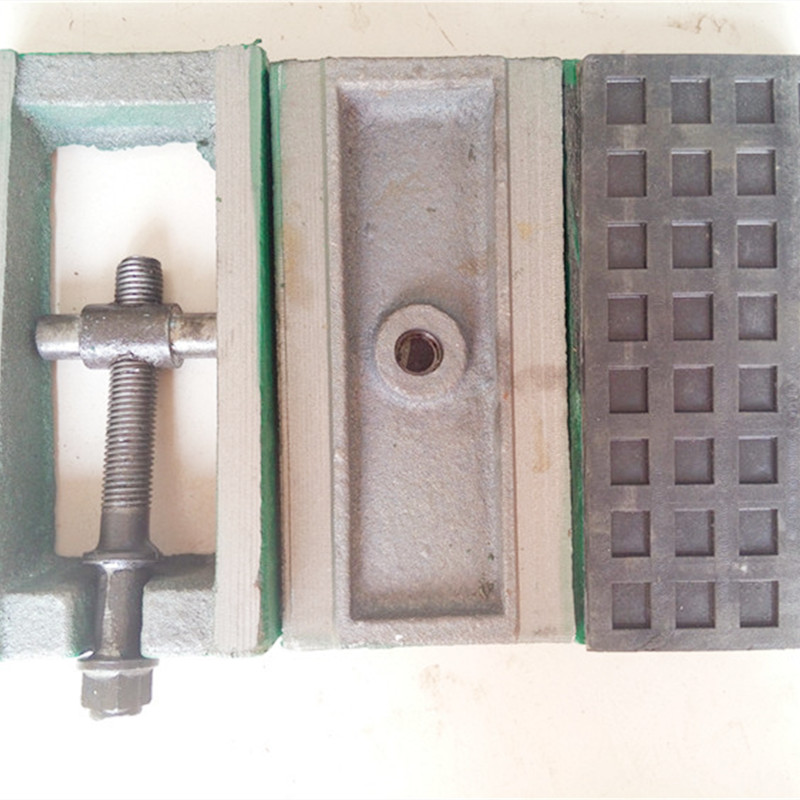

4 Inch Magnetic V Block for Precision Machining and Welding Applications

The Versatility of the 4-Inch Magnetic V Block in Precision Machining

In the realm of precision machining, the tools and accessories employed play a pivotal role in determining the effectiveness and accuracy of the workpieces being produced. One such indispensable tool used by machinists and engineers alike is the magnetic V block, particularly the 4-inch variant. This compact yet robust tool serves a variety of applications and showcases several features that contribute to its widespread use in the industry.

What is a Magnetic V Block?

A magnetic V block is a specialized workholding device designed to securely hold cylindrical or irregularly shaped workpieces in a vertical or horizontal position. The V in its name refers to the V-shaped channel that accommodates various diameters of round stock, ensuring stability during machining processes. The 4-inch version, while small in size, is powerful and versatile, making it a favorite among machinists for tasks requiring precision.

Key Features and Benefits

1. Strong Magnetic Base One of the standout features of a magnetic V block is its strong magnetic base, which allows it to attach securely to metal surfaces. This ensures that the block remains in place, providing a stable platform for machining without the risk of slipping or shifting. This reliability is crucial when working with tight tolerances and intricate designs.

2. Compact Size The 4-inch dimension makes this V block particularly portable and easy to integrate into various work environments. Its compact size does not compromise its functionality; instead, it offers the ability to handle a diverse range of workpieces, making it suitable for small-scale projects as well as larger industrial applications.

magnetic v block 4 inch

3. Versatile Mounting Options The design of the magnetic V block permits various mounting orientations. It can be used on surface plates, milling machines, lathes, and other pieces of equipment that require precise alignment. This versatility means that the same tool can effectively serve different machining needs, reducing the need for multiple accessories.

4. Durability High-quality materials are often used in the construction of these V blocks, ensuring they can withstand the rigors of a machine shop environment. The magnetic components and structural integrity allow for consistent performance over time, making them a worthy investment for any machinist.

5. Ease of Use Using a magnetic V block is straightforward; simply place the workpiece in the V groove, engage the magnetic base, and it’s ready for machining. This user-friendly design translates to increased efficiency, allowing machinists to spend less time on setup and more on production.

Applications in Machining

The 4-inch magnetic V block is particularly useful in various machining operations, including grinding, milling, and drilling. It is ideal for aligning shafts for precise drilling operations, checking runout on rotating components, and even in inspection tasks where maintaining the integrity of the workpiece is crucial. Its ability to hold workpieces securely while allowing access from multiple angles enhances productivity and accuracy.

Conclusion

In conclusion, the 4-inch magnetic V block is a vital tool in the field of precision machining. Its compact size, strong magnetic hold, and versatility make it indispensable for a variety of tasks, from basic alignment to complex machining operations. With durability and ease of use, this tool exemplifies efficiency in the workshop, ensuring that both novice and experienced machinists can achieve high levels of precision in their work. As technology continues to evolve, the reliability and effectiveness of tools like the magnetic V block will remain a cornerstone of successful machining practices.

-

Why Metric Trapezoidal Thread is Ideal for Precision Motion ControlNewsAug.05,2025

-

The Unique Properties of a Block of Granite for Industrial UseNewsAug.05,2025

-

The Role of Flanged Y Strainers in Preventing Pipeline ClogsNewsAug.05,2025

-

The Importance of Regular Calibration for Master Ring GagesNewsAug.05,2025

-

How a Cast Iron Surface Table Enhances Accuracy in ManufacturingNewsAug.05,2025

-

Comparing Different Check Valve Types for Optimal Flow ControlNewsAug.05,2025

Related PRODUCTS