ਅਕਤੂਃ . 16, 2024 10:01 Back to list

Top Globe Valve Manufacturers and Their Innovative Solutions in the Industry

The Importance of Globe Valve Manufacturers in Industrial Applications

Globe valves have long been a crucial component in various industrial applications, offering precise flow control and efficient operation. As industries around the globe continue to develop and expand, the role of globe valve manufacturers becomes ever more significant. This article will delve into the importance of these manufacturers, the complexities of globe valve design, and how they contribute to ensuring optimal performance in a wide range of settings.

Understanding Globe Valves

Globe valves are named for their spherical body shape. They are primarily used for regulating flow, unlike gate valves, which are typically used for on/off control. The internal structure of a globe valve includes a movable disk (or plug) and a stationary ring seat, which work together to control the flow of the fluid. This design allows for highly accurate control, making globe valves ideal for applications where flow regulation is critical.

The Role of Globe Valve Manufacturers

Globe valve manufacturers play a vital role in the industrial supply chain

. They are responsible for designing, producing, and distributing these crucial components, ensuring that they meet rigorous industry standards and specifications.1. Quality Control and Standards Globe valve manufacturers adhere to various domestic and international standards to ensure that their products are safe and reliable. Compliance with standards such as the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) is essential for maintaining quality and trust among customers. Regular inspections and testing throughout the manufacturing process guarantee that each valve will perform optimally under expected conditions.

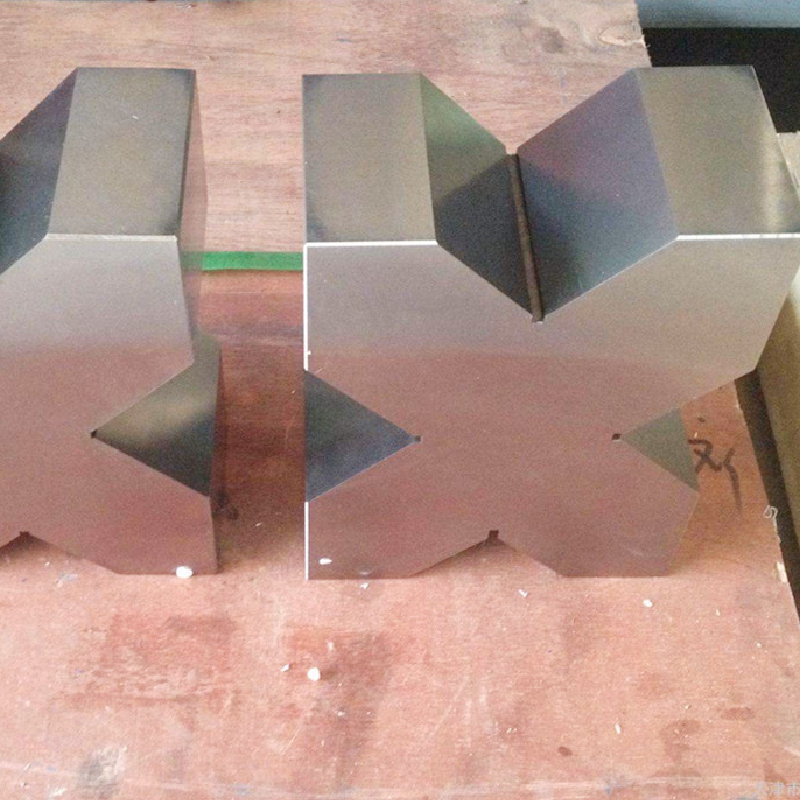

globe valve manufacturer

2. Innovation in Design Continuous innovation in valve design allows manufacturers to create more efficient and functional products. Using advanced materials, such as stainless steel and other high-performance alloys, manufacturers can produce globe valves that withstand harsh environments, high pressures, and extreme temperatures. Additionally, new designs can incorporate features like automatic controls or actuation systems that enhance the usability of globe valves in automated systems.

3. Customization Options Different industries have different requirements regarding valve functionality, size, and materials. Recognizing this need, globe valve manufacturers often offer customization options. This flexibility allows clients to tailor solutions to their unique specifications, whether for oil and gas, chemical processing, or water treatment applications.

4. Sustainability and Environmental Impact As global industries increasingly focus on sustainability, globe valve manufacturers are also adapting by producing eco-friendly designs and reducing waste in the manufacturing process. By investing in sustainable practices, these manufacturers not only contribute to environmental protection but also align their products with the growing demand for green technology.

5. Customer Support and Service A commitment to customer service is a hallmark of reputable globe valve manufacturers. They provide technical support to help clients select the appropriate valve for their specific needs and ensure proper installation and maintenance. Offering training and resources helps ensure that users can operate and maintain their valves effectively, extending the product’s lifespan and performance.

Conclusion

In conclusion, globe valve manufacturers are essential players in the industrial landscape. Their contributions to the design, production, and distribution of these critical components ensure that various industries can operate smoothly and efficiently. By adhering to quality standards, fostering innovation, offering customization, adopting sustainable practices, and providing exceptional customer support, globe valve manufacturers are instrumental in supporting the modern industrial world. As technology continues to evolve and industries adapt to new challenges, the role of these manufacturers will undoubtedly remain integral, paving the way for a future defined by precision and reliability in fluid management.

-

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS