ਨਵੰ. . 11, 2024 15:47 Back to list

cast iron surface plate price

Understanding the Pricing of Cast Iron Surface Plates

Cast iron surface plates have long been an essential tool in various industries, particularly in manufacturing and quality control. Their durability, stability, and precision make them a popular choice for providing a flat reference surface. However, when considering the investment in a cast iron surface plate, one of the most significant factors is its price. This article delves into the factors influencing the prices of cast iron surface plates and how to make informed purchasing decisions.

Factors Influencing Price

1. Material Quality The composition of the cast iron is paramount. Plates made from high-quality gray iron or ductile iron tend to be more expensive due to their superior characteristics. High-grade cast iron ensures better stability, reduces thermal expansion, and provides a longer lifespan, making them more cost-effective despite a higher initial price.

2. Manufacturing Process The way a surface plate is manufactured impacts its cost. High-precision surfacing techniques are employed to ensure that the plate meets stringent flatness tolerances. More sophisticated manufacturing processes that include vibration dampening and heat treatment can increase the price of the final product, but they also enhance performance.

3. Size and Thickness Surface plates come in a range of sizes and thicknesses. Larger and thicker plates generally command higher prices due to the increased material costs and the complexities involved in manufacturing them. Buyers must assess their operational needs to determine the most appropriate size without overspending on unnecessary features.

4. Brand and Reputation Different manufacturers offer various price points based on their brand reputation and market position. Renowned manufacturers with a history of producing high-quality cast iron products often charge a premium. However, investing in a well-regarded brand can provide peace of mind regarding quality and support.

5. Market Conditions Prices can fluctuate based on market conditions, including the availability of raw materials and changes in demand. For instance, if the demand for industrial equipment rises, it could drive prices up. Keeping an eye on market trends can give buyers an advantage in timing their purchases.

cast iron surface plate price

6. Additional Features Some cast iron surface plates come with additional features such as accessory options (like height gauges and surface plate stands), leveling pads, or coatings to prevent rust. These features can enhance usability and precision but will also add to the overall cost.

Average Price Ranges

As a general guideline, the price of cast iron surface plates can vary widely based on the above factors. Smaller plates (e.g., 18 x 24) might cost between $200 to $600, while larger plates (e.g., 36 x 48) can range from $1,000 to over $3,000, depending on quality and precision requirements. Custom sizes or those that require special features can significantly increase costs, sometimes reaching upwards of $5,000 or more.

Evaluating Investment Value

When evaluating the price of cast iron surface plates, it’s crucial to look beyond the sticker price. Consider the cost-benefit analysis of the investment. A high-quality plate may require a larger initial outlay but can save costs in the long run through enhanced durability, fewer replacements, and improved accuracy in measurements, which can prevent costly errors in manufacturing processes.

Conclusion

Purchasing a cast iron surface plate is not just about the initial price—it’s an investment in quality and precision. By understanding the factors that influence pricing, potential buyers can make informed decisions that best suit their operational needs and budget. Whether outfitting a workshop or enhancing an existing quality control system, selecting the right cast iron surface plate, considering factors beyond just cost, will ultimately lead to more sustainable efficiency and productivity in the long run.

-

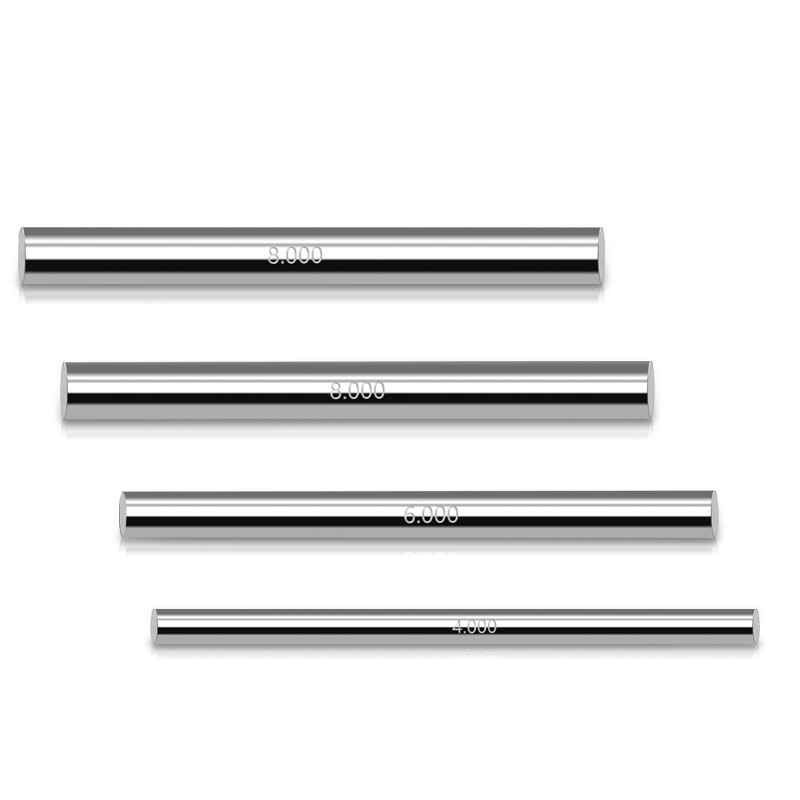

Hardened Pin Gauge Resists Wear from Frequent UseNewsJul.15,2025

-

Gate Valve Ensures Reliable Flow Control in PipelinesNewsJul.15,2025

-

Threaded Ring Gauge Measurement UncertaintyNewsJul.14,2025

-

Spirit Level Ruler Calibration CheckNewsJul.14,2025

-

Magnetic V Block Material GradesNewsJul.14,2025

-

Indicating Micrometer Digital DisplaysNewsJul.14,2025

Related PRODUCTS