ਦਸੰ. . 06, 2024 01:35 Back to list

Exploring the Features and Applications of 18% Butterfly Valve in Industrial Settings

The Significance of the 18% Butterfly Valve in Industrial Applications

Butterfly valves are essential components in various industrial applications, serving as critical instruments for controlling the flow of fluids in pipelines. Among the many types of butterfly valves available in the market, the 18% butterfly valve holds a particular significance, especially in industries that require precise flow regulation and handling of different media.

Understanding Butterfly Valves

Butterfly valves are quarter-turn rotational devices that utilize a disk or butterfly to regulate flow. When the valve is fully open, the disk is parallel to the flow, minimizing resistance and allowing maximum flow capacity. Conversely, when the valve is closed, the disk rotates to a position perpendicular to the flow, effectively blocking it. The simple design and ease of operation make butterfly valves an attractive choice for many applications.

Features and Benefits of the 18% Butterfly Valve

The term 18% butterfly valve typically refers to the specific design or configuration that caters to flow characteristics that can handle 18% of the total flow capacity in a given system. This designation can relate to the valve's size, design, or its functionality for particular applications.

Some key features that make the 18% butterfly valve valuable are

1. Flow Control and Regulation The 18% valve allows for fine control of fluid flow, enabling operators to adjust settings easily for precise applications. This feature is crucial in processes where specific flow rates must be maintained to ensure optimal performance and product quality.

2. Space Efficiency Compared to other types of valves, butterfly valves, including the 18% variety, are relatively compact. This space-saving design is advantageous in facilities where space is at a premium, allowing for easy installation and maintenance without excessive modifications to existing structures.

3. Cost-Effectiveness Butterfly valves are generally more economical than other valve types, such as gate or globe valves. As a result, the 18% butterfly valve provides an affordable solution for industries looking to enhance their operations without incurring significant costs.

18 butterfly valve

4. Versatility The 18% butterfly valve is suitable for a wide range of media, including water, oils, gases, and slurries. This versatility makes it a popular choice across different sectors, such as wastewater treatment, chemical manufacturing, food and beverage processing, and HVAC systems.

5. Durability and Reliability Constructed from a variety of materials, including stainless steel, cast iron, and plastic, the 18% butterfly valve can withstand harsh conditions. Its robust design ensures a long service life, thereby reducing the need for frequent replacements and maintenance.

Applications of the 18% Butterfly Valve

The 18% butterfly valve finds applications in various industries due to its unique advantages.

1. Water and Wastewater Management In water treatment plants and municipal wastewater systems, the valve plays a vital role in regulating flow and controlling discharge rates. It ensures efficient management of resources while minimizing potential environmental impacts.

2. Pumping Stations In pumping stations, the valve’s ability to handle varying flow rates aids in maintaining system balance. Proper flow control prevents equipment damage and optimizes pump performance.

3. Chemical Processing The chemical industry requires valves that can operate safely under high pressure and corrosive conditions. The 18% butterfly valve's materials and design make it a solid choice for handling a wide range of chemicals without compromising safety.

4. HVAC Systems In heating, ventilation, and air conditioning applications, butterfly valves are employed to regulate airflow and maintain desired temperature levels. The 18% variant ensures efficiency in heating and cooling processes.

Conclusion

In conclusion, the 18% butterfly valve serves as a crucial component in numerous industrial applications, offering reliable flow control, versatility, and space efficiency. Its cost-effectiveness and robust design contribute to its popularity across various sectors. As industries continue to evolve and demand more sophisticated solutions for fluid management, the significance of the 18% butterfly valve will only grow, ensuring that it remains a key player in modern industrial innovations.

-

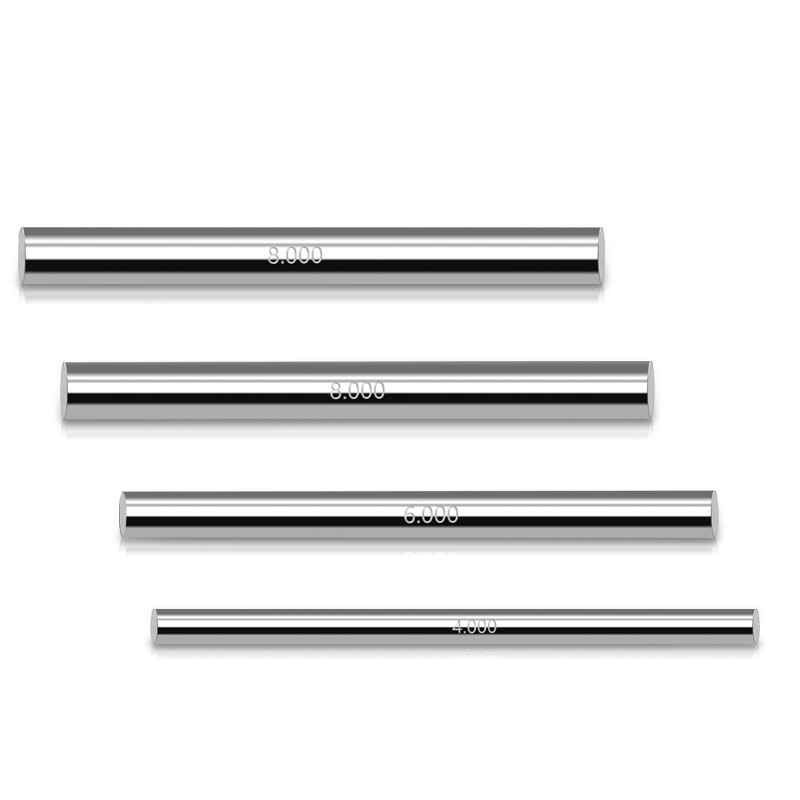

thread-plug-gauge-our-promise-of-measurement-excellenceNewsAug.22,2025

-

gauge-pin-class-reflecting-quality-legacyNewsAug.22,2025

-

check-valve-types-for-high-rise-buildingsNewsAug.22,2025

-

water-control-valve-for-irrigation-systemsNewsAug.22,2025

-

gate-valve-with-soft-seal-technologyNewsAug.22,2025

-

y-type-strainer-for-oil-and-gas-applicationsNewsAug.22,2025

Related PRODUCTS